Automatic material taking control device and method of material piling and taking machine

A technology of automatic reclaiming and control method, applied in the field of stacker reclaimer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

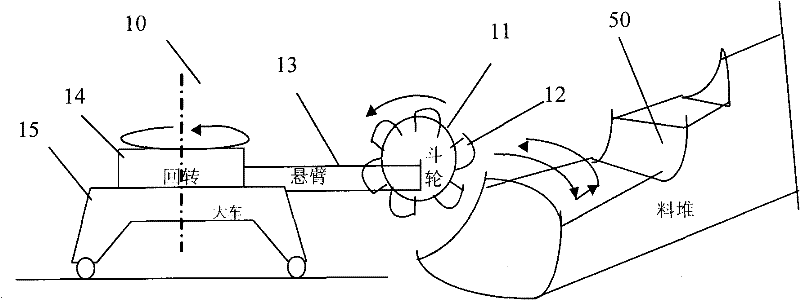

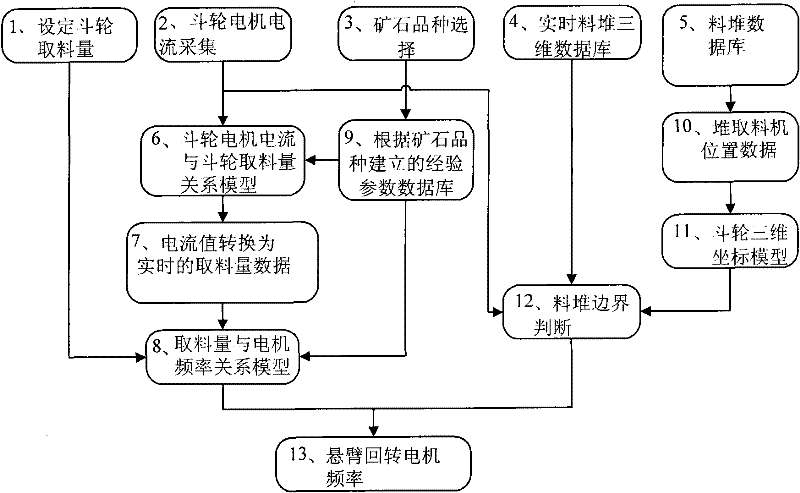

[0057] refer to figure 1 1. During the reclaiming operation of the stacker-reclaimer 10, the rotational speed of the bucket wheel 11 itself is constant, and the speed of the rotary mechanism 14 is adjustable. The faster the revolving speed, the higher the reclaiming capacity of the bucket wheel 11. The higher the amount of material taken, the greater the current of the bucket wheel motor that drives the bucket wheel 11 to rotate itself.

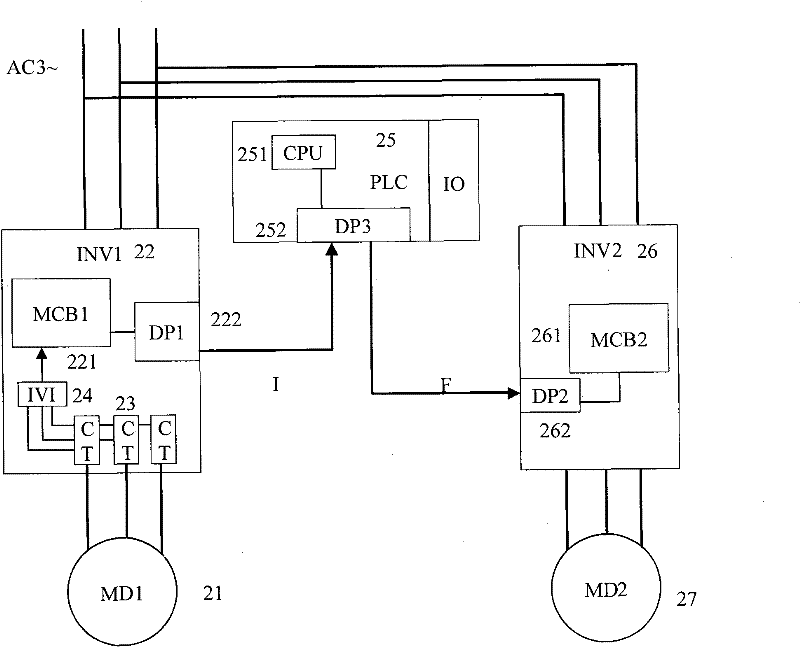

[0058] The present invention is by sampling the current value of the bucket wheel motor of the stacker reclaimer 10, and establishes a corresponding functional relationship with the actual bucket wheel reclaiming amount and the frequency and speed of the rotary motor that drives the rotary mechanism 14 to rotate. In the control, the current of the bucket wheel motor is used as a negative feedback signal to automatically adjust the rotation speed of the driving rotary mechanism 14 (the rotation speed of the cantilever 13) when taking materials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com