Full-automatic cleaning treatment assembly line for high-clean battery cover plate

A battery cover, cleaning technology, applied in cleaning methods and utensils, cleaning methods using tools, cleaning methods using liquids, etc., can solve problems such as unguaranteed cleaning quality and secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings, but does not constitute any limitation to the present invention. Similar component numbers in the accompanying drawings represent similar components. As mentioned above, the present invention provides a fully automatic assembly line for cleaning the battery cover plate with high cleanliness, which is used to realize the fully automatic cleaning process for the battery cover plate, so as to ensure the service life of the battery.

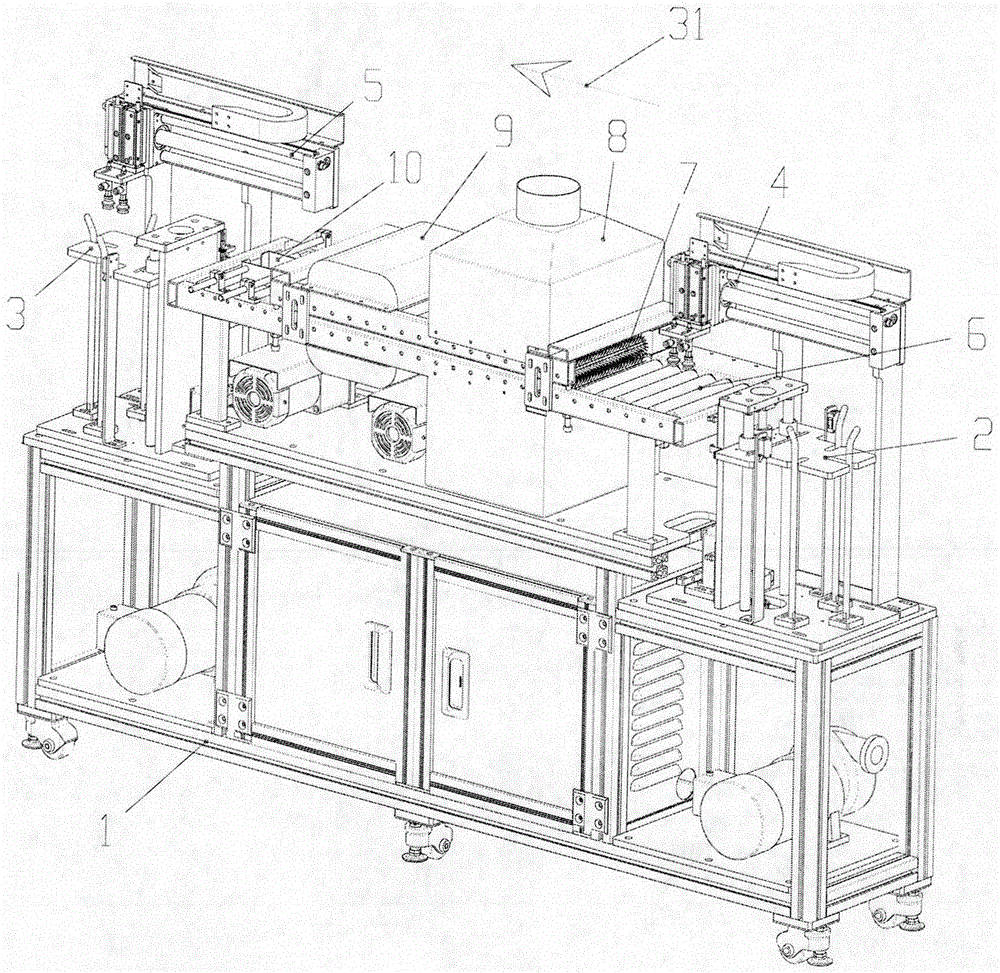

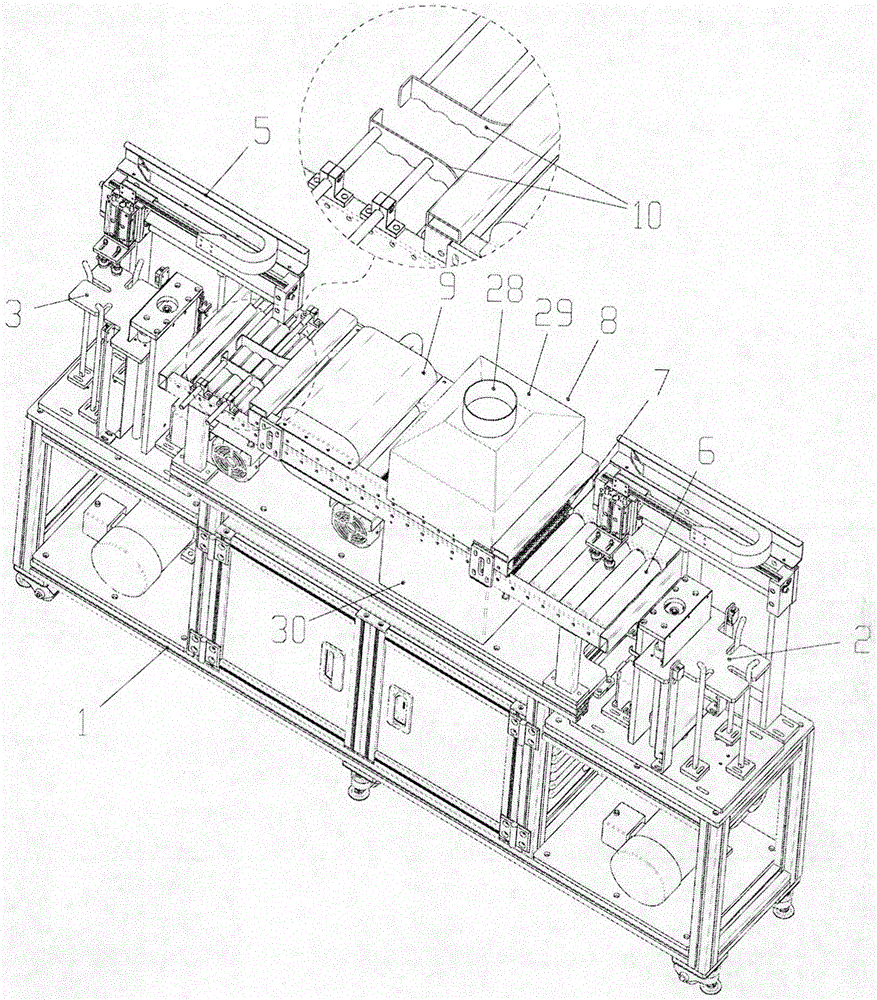

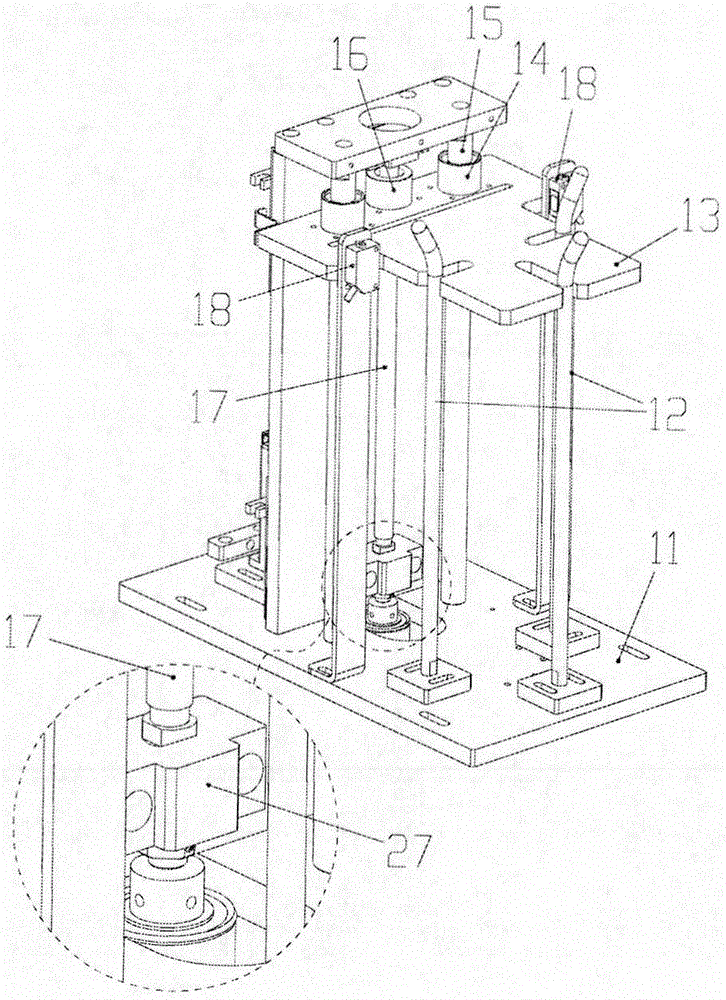

[0025] figure 1 It is a schematic diagram of the three-dimensional structure of the fully automatic assembly line for cleaning the high-clean battery cover plate of the present invention, figure 2 It is a structural schematic view of the fully automatic assembly line for cleaning the high-clean battery cover plate of the present invention from another perspective, image 3 , 4 It is a structural schematic diagram of the dynamic fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com