Full-automatic guide valve comprehensive performance testing platform

A comprehensive performance testing, fully automatic technology, used in fluid tightness testing, mechanical component testing, machine/structural component testing, etc., to solve problems such as high safety hazards, low work efficiency, and heavy manual operation workload. , to achieve the effect of high reliability, stable equipment operation and accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

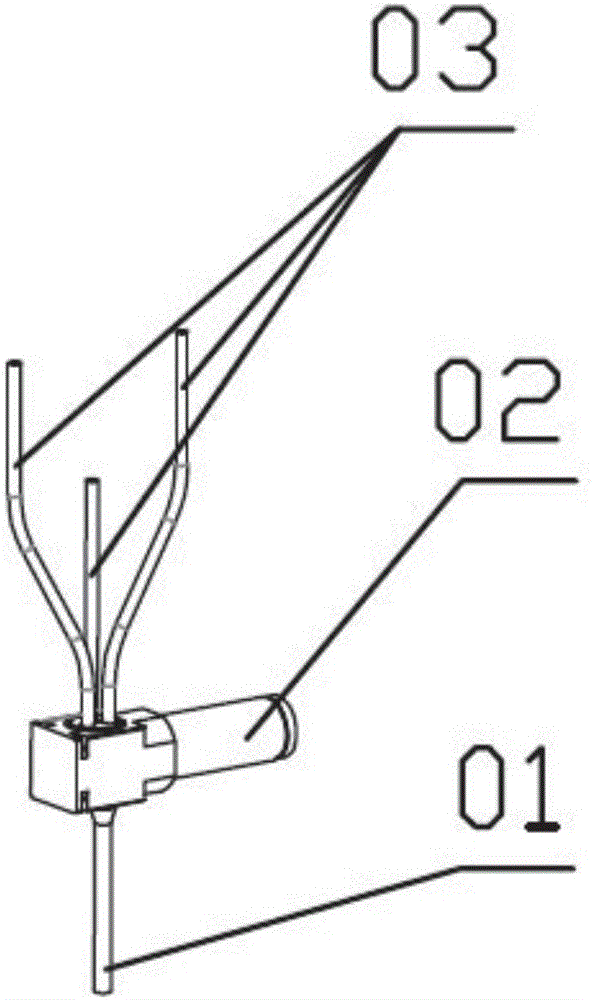

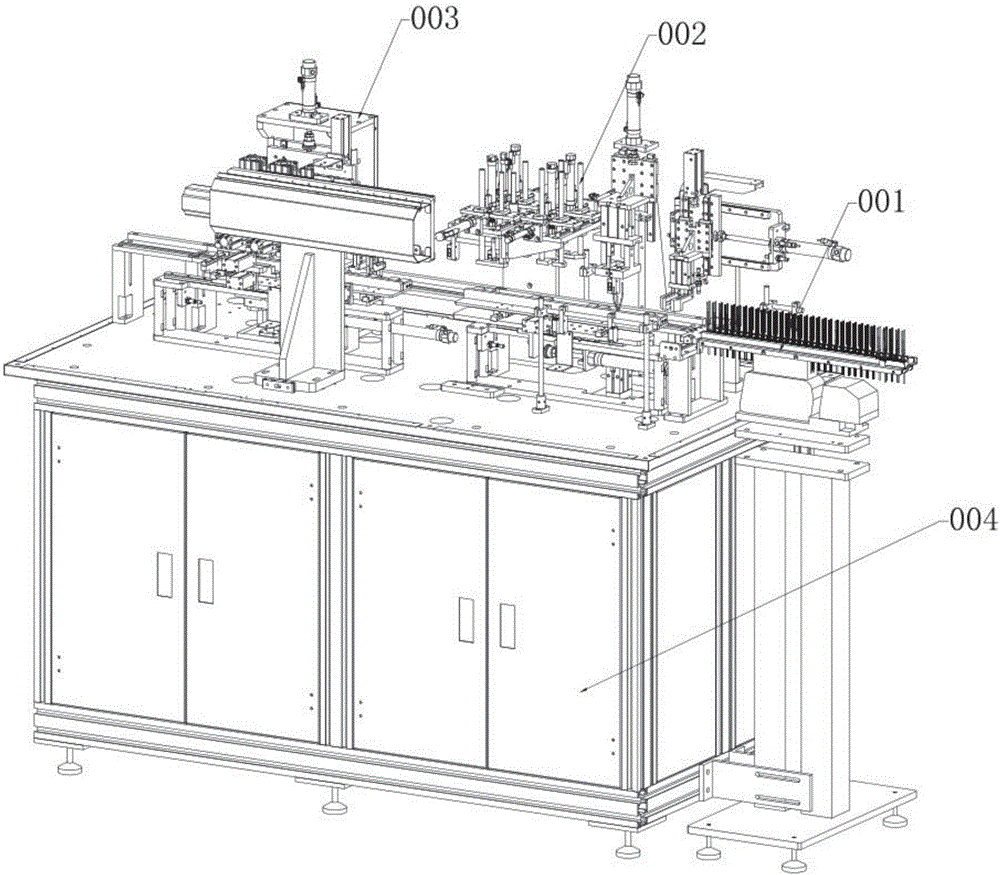

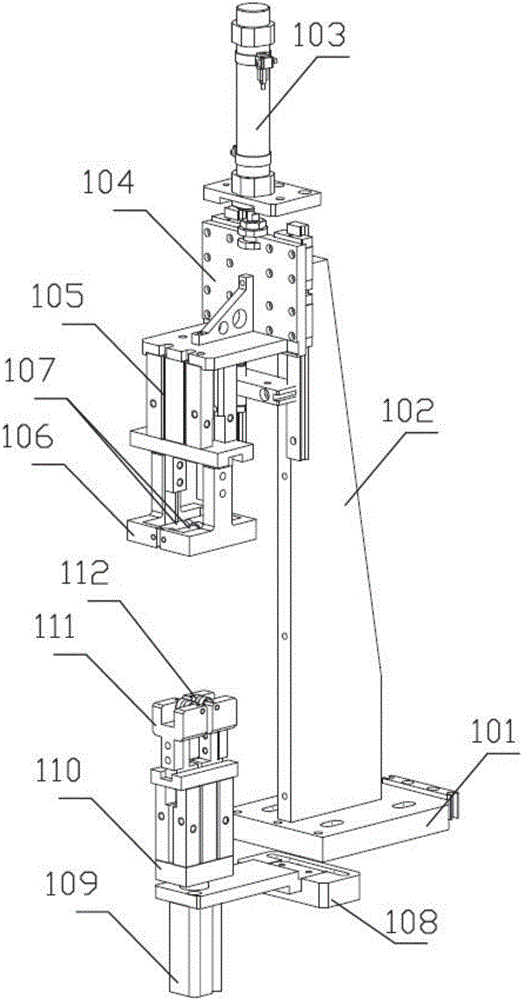

[0027] combined with figure 2 to attach Figure 9 , a fully automatic pilot valve comprehensive performance test bench, which includes a feeding device 001, a shaping device 002, a sealing device 003, a test frame 004, a detection valve island 005 and an electrical control system; the feeding device 001, the shaping device 002, Both the sealing device 003 and the detection valve island 005 are installed on the test frame 004; the feeding device 001 is used to transport the test piece through the shaping device 002, the sealing device 003 and the detection valve island 005 in turn, and then put it into the designated area according to the test results ; The shaping device 002 is used to comb the pipeline of the test piece into a regular product that is straight, each tube is parallel to the same plane and the ESC tube interval is 36mm; the sealing device 003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com