Car washing method

A car washing and car washing machine technology, applied in the field of machinery, can solve the problems of no sewage recycling function, large environmental pollution, poor controllability of engineering quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be further described below in conjunction with accompanying drawing.

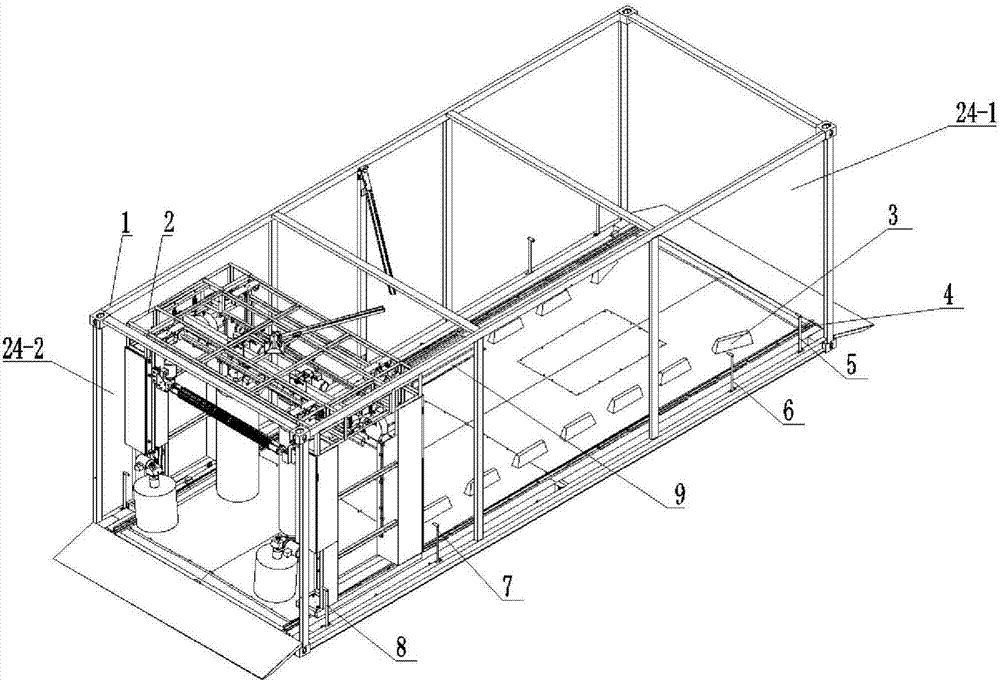

[0068] Such as figure 1 As shown, a relocatable integrated car washing machine adopted in a car washing method includes a control system, a frame, a water circulation system 1 and a car washing system 2 .

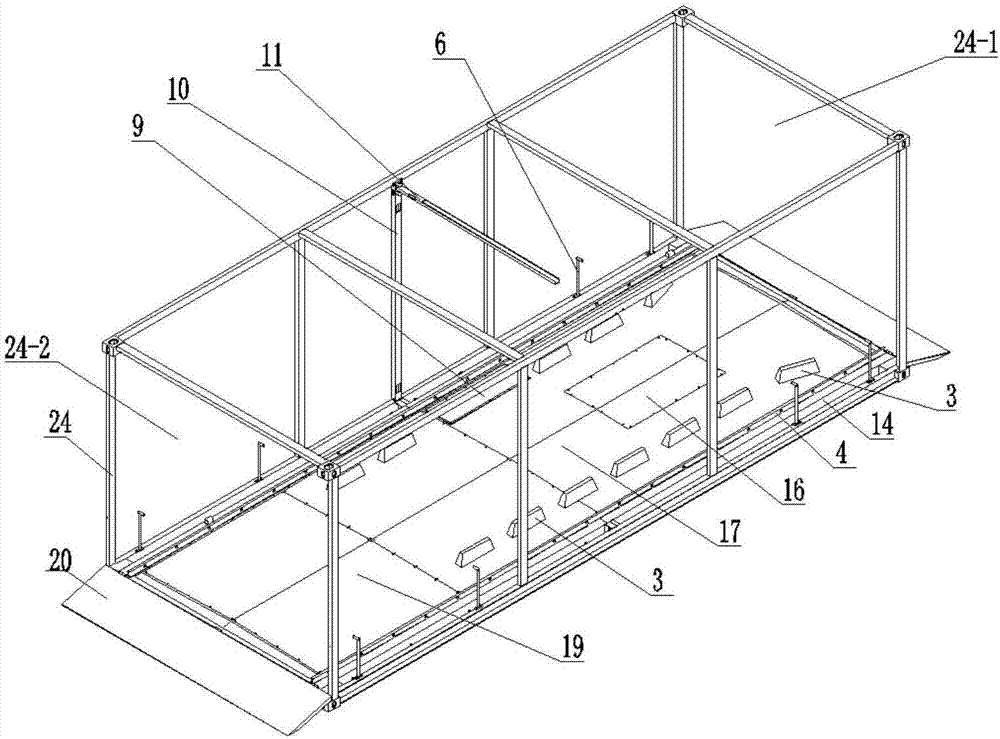

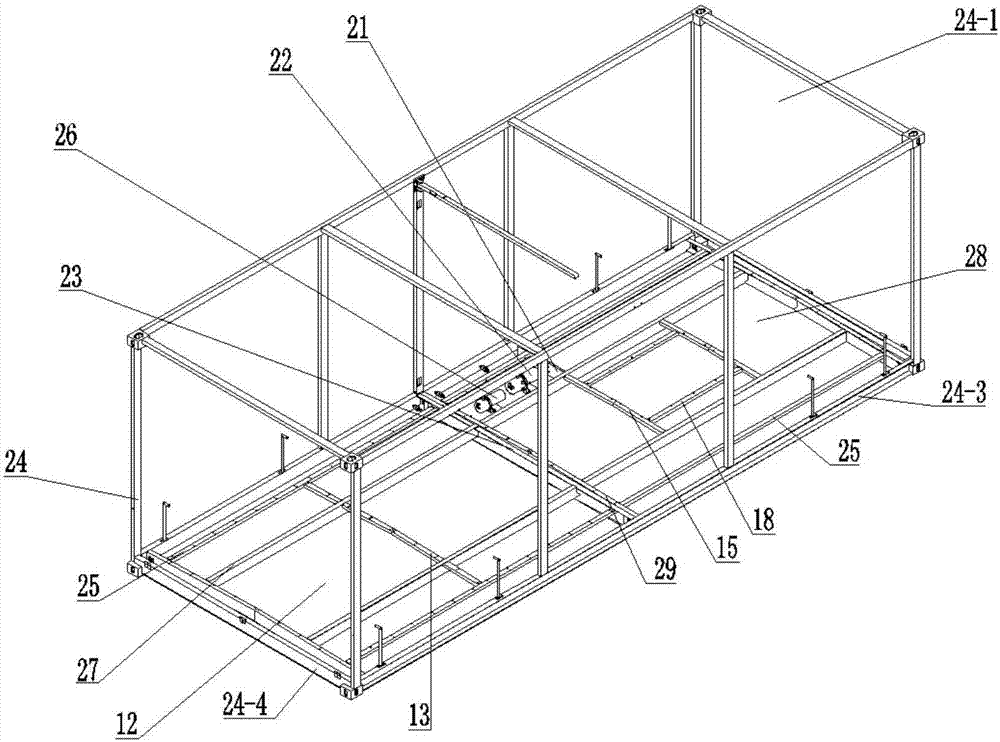

[0069] Such as figure 2 and 3 As shown, the frame and water circulation system 1 includes an outer frame 24, a wheel aligner 3, a traveling guide rail 4, a first positioning assembly 5, a second positioning assembly 6, a third positioning assembly 7, a fourth positioning assembly 8, and a sealed cabin cover 9 , water pipe guide rod 10, water pipe swing rod 11, sewage plate support frame 13, sewage tank plate 14, water purification plate support frame 15, water purification moving plate 16, water purification fixed plate 17, water purification plate support beam 18, sewage cover Plate 19, ramp plate 20, sealing plate 21, clean water pump 22, partition beam 23, guide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com