Medium-drive dirt cleaning machine for transmission pipelines

A technology of conveying pipeline and cleaning machine, applied in the field of machinery, can solve the problems of removing the dirt of conveying pipeline, and achieve the effect of good cutting effect and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

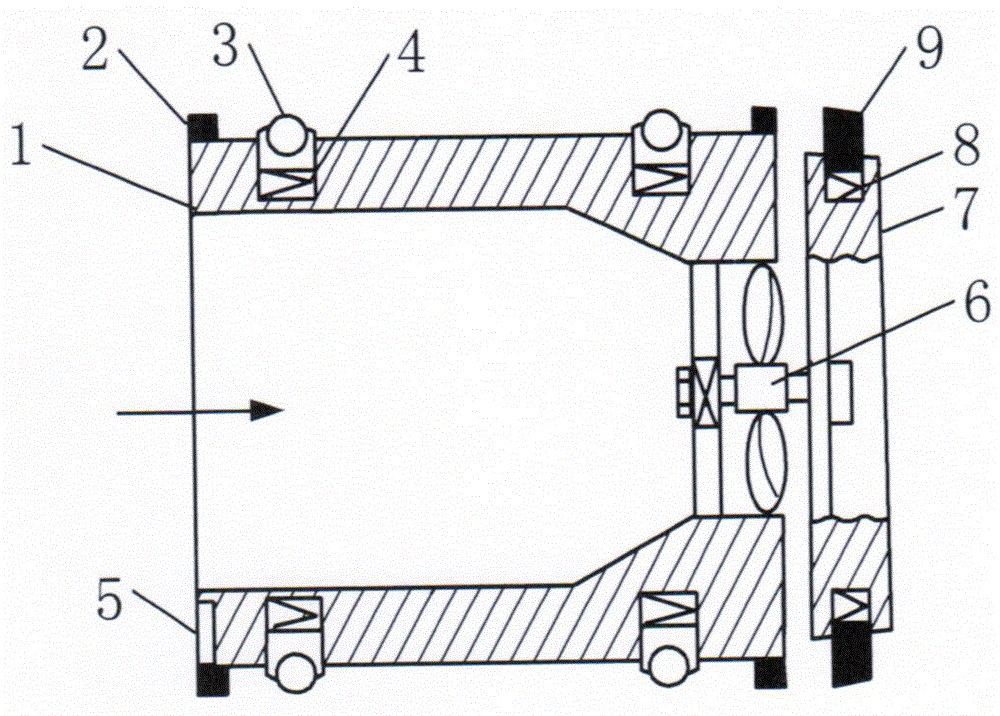

[0011] according to figure 1 As shown, sealing rings 2 are set on the front and rear sides of the cylinder body 1, and the walking support wheel 3 is installed through the compensation spring 4. The cutting head 7 is installed on the front of the cylinder body through the rotating shaft, and the cutting head ring passes through the cutter spring 8. A cutting tool 9 is installed.

[0012] A positioning sensor 5 is installed on the cylinder wall.

[0013] The driving rotating mechanism 6 is an impeller.

[0014] The front end of the barrel is provided with a conical diversion chamber.

[0015] The diversion cavity increases the flow rate of the liquid passing through the cylinder, and the generated rotational force and torque are large, which can make the cutting head rotate with a relatively large torque.

Embodiment 2

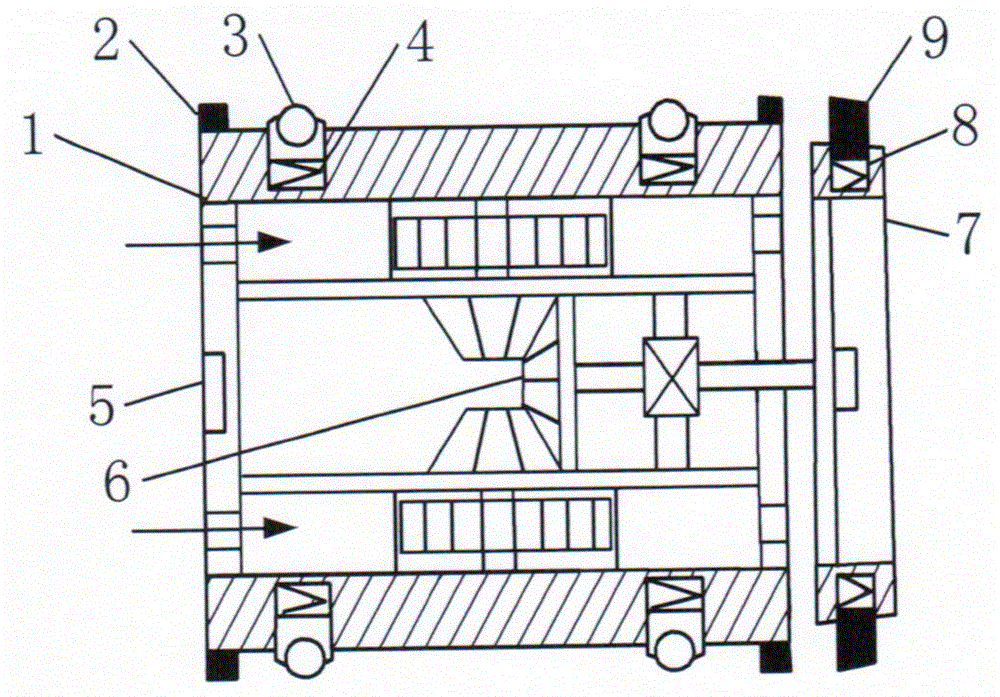

[0017] according to figure 2 As shown, there are blocking plates on both sides of the cylinder, medium inlets and medium outlets on the blocking plates, and impellers are installed in the formed diversion cavity, which are connected with bevel gears. The bevel gear is meshed with the bevel gear for transmission connection, and the bevel gear is installed and connected with the cutting head through a shaft.

[0018] The driving rotation mechanism is driven by impeller, bevel gear and bevel gear. The diversion cavity is arranged on the front and rear blocking plates.

[0019] When the bevel gear and the bevel gear are meshed for transmission, when the cutting head has a large torque and stalls, the cylinder is pushed forward by the medium to increase the thrust.

[0020] Positioning sensors are installed on the blocking plate.

[0021] The cutting head is a conical body, and the outer edge is provided with one to three layers of cutting tools arranged at a distance.

[0022...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com