Train loading and unloading integrated machine

An all-in-one machine and train technology, which is applied in the direction of loading/unloading, conveyors, conveyor objects, etc., can solve the problems of unadjustable loading and unloading height, high labor intensity, and difficulty in meeting loading and unloading needs, and achieve flexible and multi-faceted operations and scope of application Wide, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and examples, and the contents of the examples are not intended to limit the protection scope of the present invention.

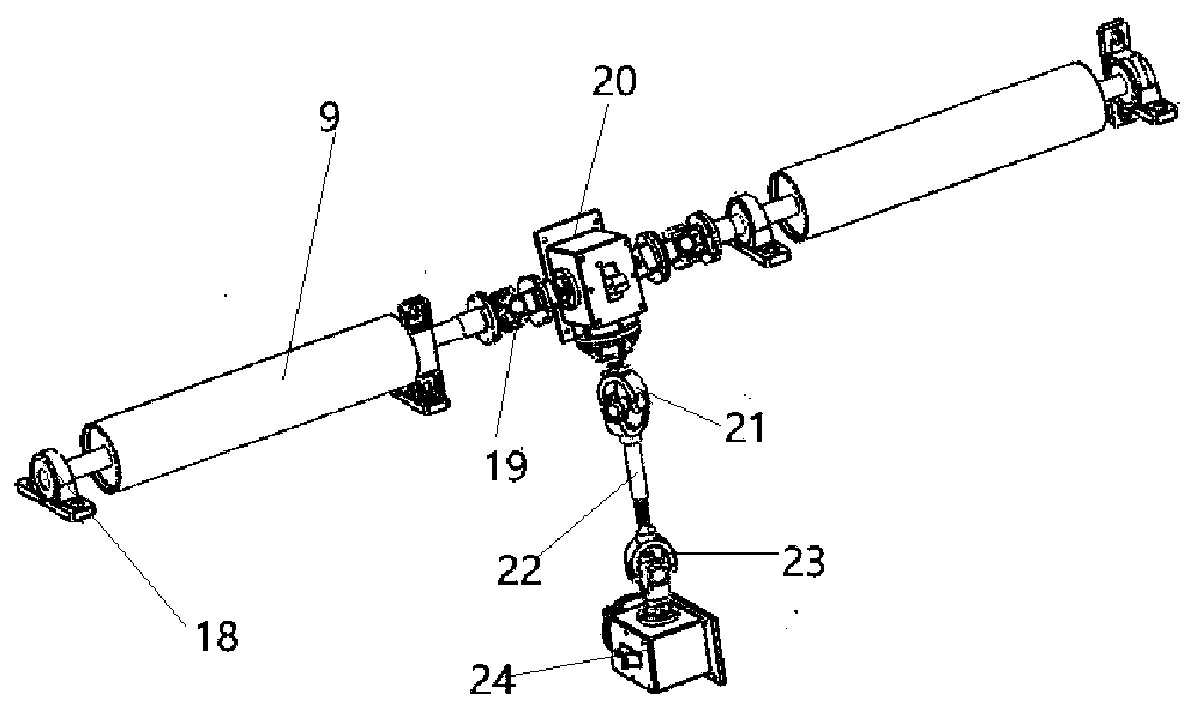

[0025] The invention relates to a train loading and unloading integrated machine, which uses the friction between the outer surface of the driving roller and the inner surface of the conveyor belt to make the conveyor belt move forward, so as to achieve the purpose of transporting materials to a designated position.

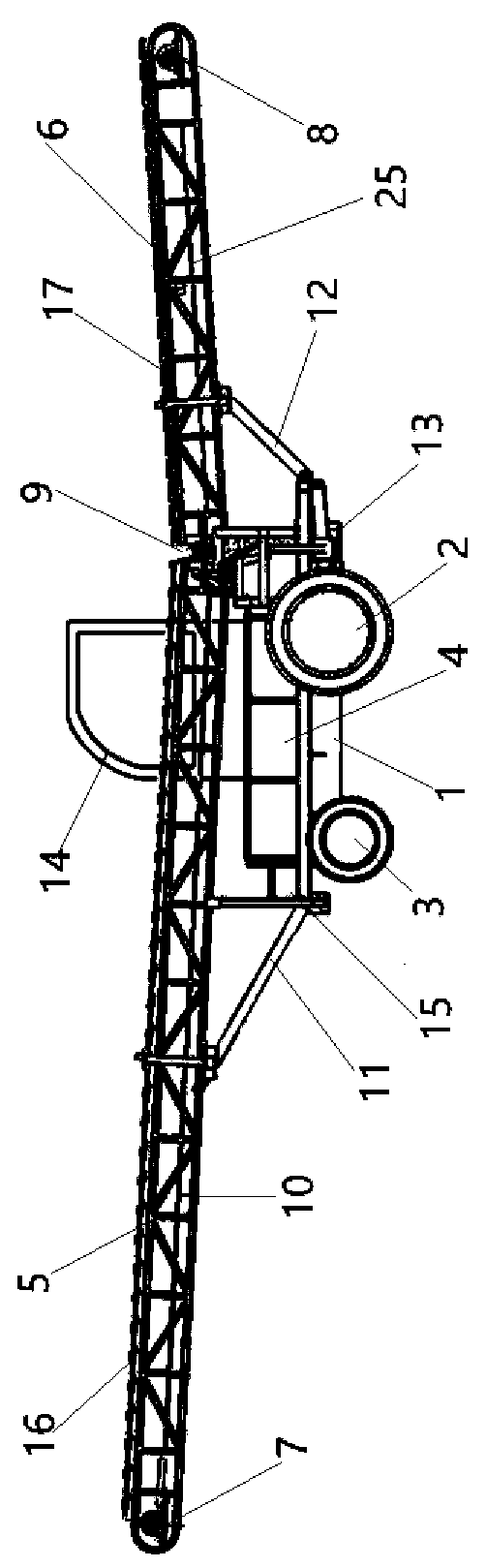

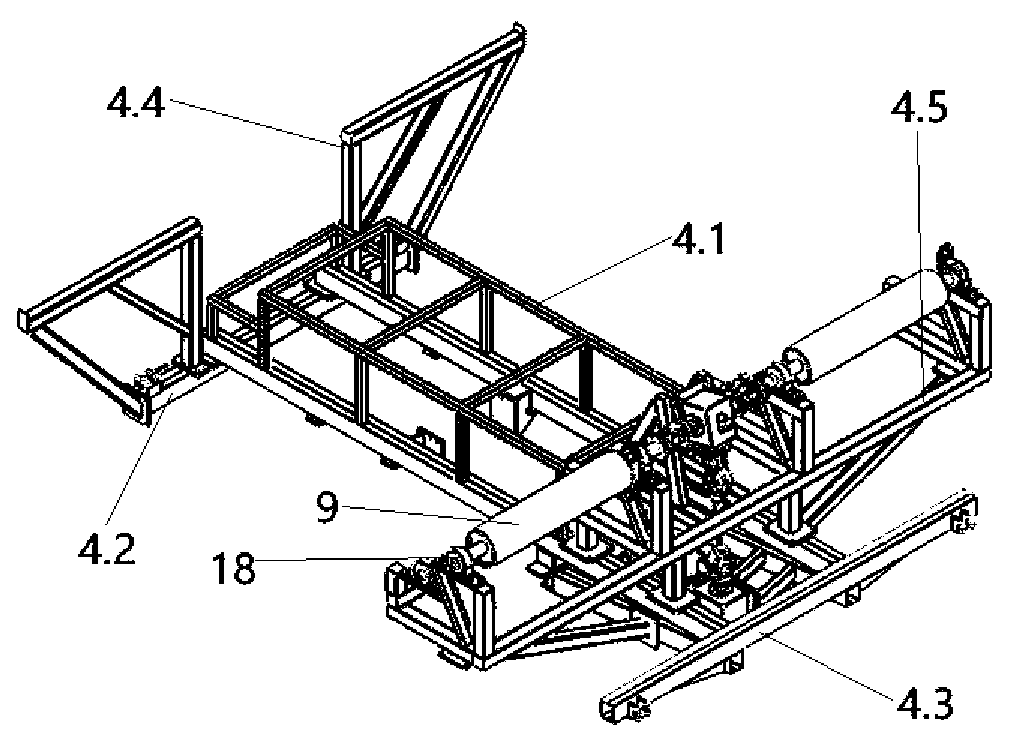

[0026] figure 1 It shows the front view of the integrated train loading and unloading machine of the present invention. Such as figure 1 As shown, the integrated train loading and unloading machine of the present invention includes a chassis 1 . The chassis 1 is used to provide support for other components of the integrated train loading and unloading machine.

[0027] Preferably, the chassis 1 is a wheeled chassis, that is, a vehicle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com