Natural gas molecular sieve adsorption dehydration system provided with heat recycling structure, and method

A technology of natural gas and molecular sieve, which is applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problems of waste of heat energy, decrease of adsorption capacity, waste of resources, etc., achieve high-efficiency dehydration operation, reduce heating load, and reduce complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

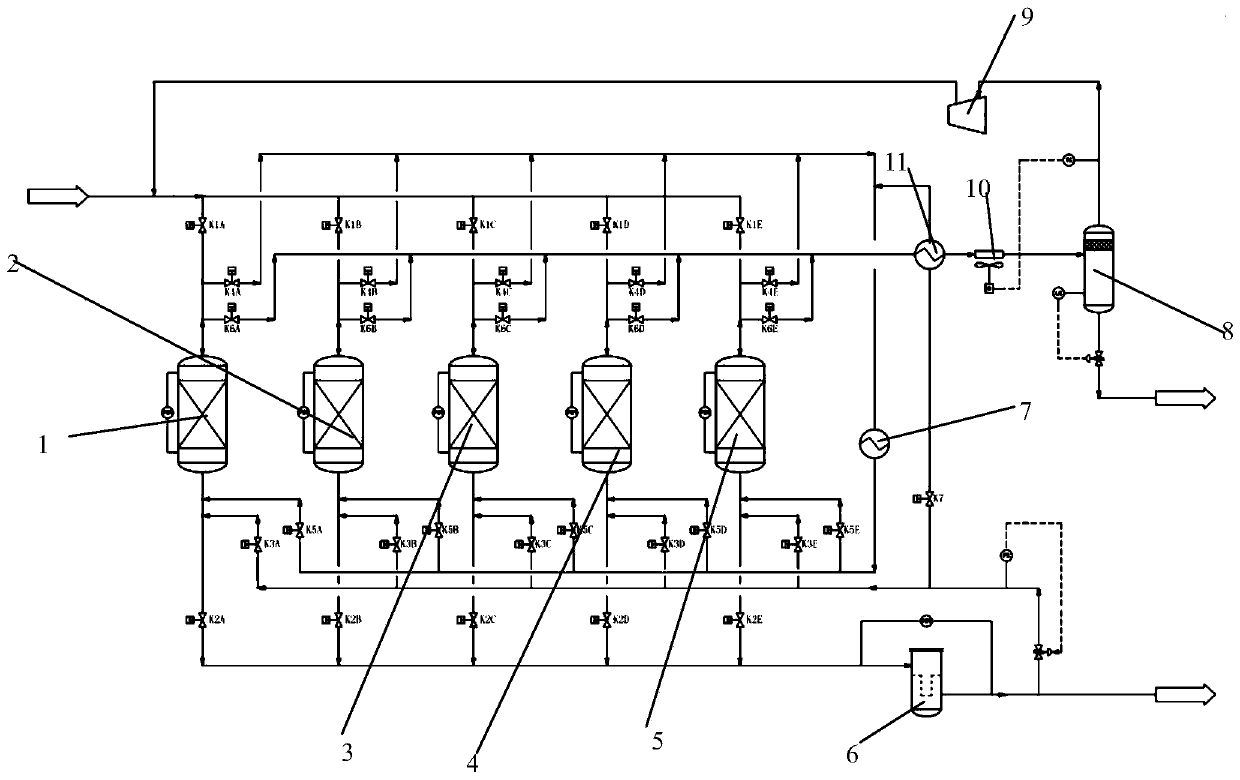

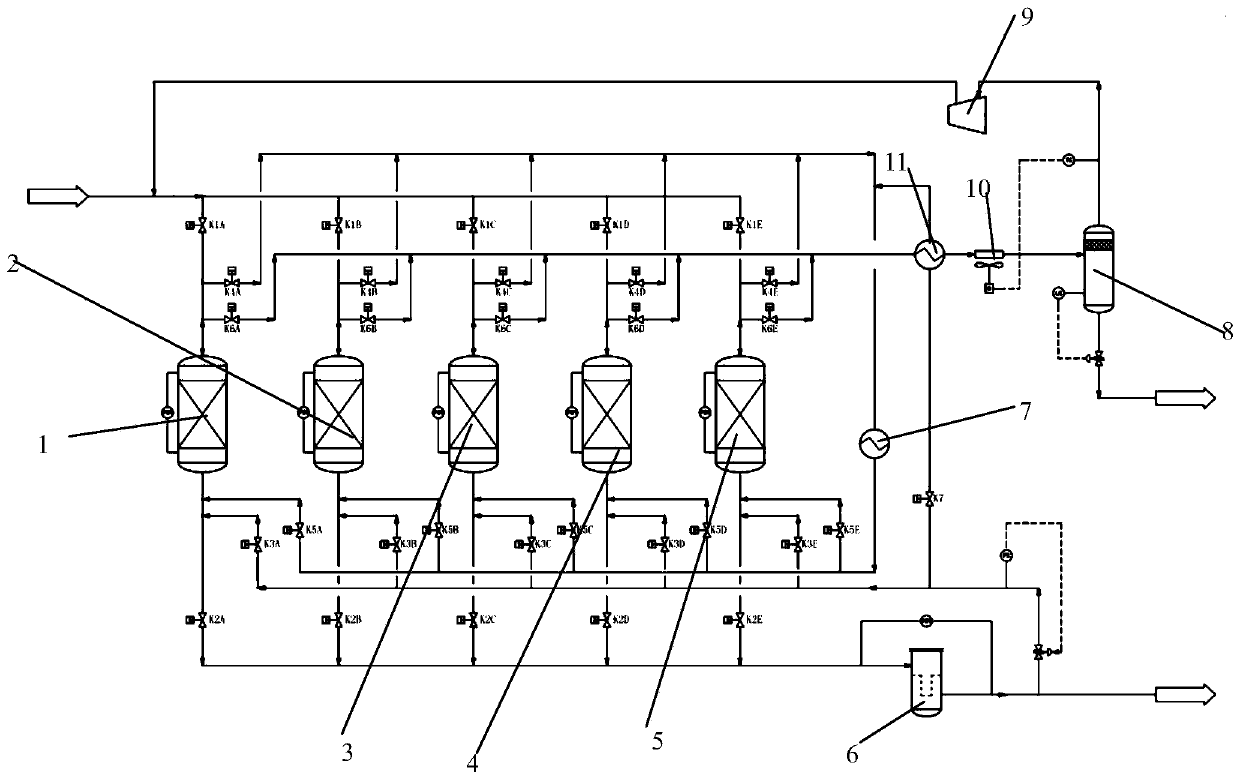

[0046] Specific embodiment 1: According to the operation sequence of adjusting the adsorption tower and each switching valve, the alternate switching of adsorption and regeneration can be realized:

[0047] When the two towers of adsorption tower A1 and adsorption tower B2 are adsorbed and dehydrated, the adsorption tower C3 is cold-regenerated, the adsorption tower D4 is hot-regenerated, and the adsorption tower E5 is standby; at this time, the adsorption tower A1 and the adsorption tower B2 are two dehydration towers, and the adsorption tower C3 is Cold regeneration tower and adsorption tower D4 are hot regeneration towers, and adsorption tower E5 is a standby tower;

[0048] Open the valves on the dehydration inlet branch pipe and the dehydration gas outlet branch pipe on the adsorption tower A1 and the adsorption tower B2, and close the valves on the cooling gas inlet branch pipe, the cooling gas outlet branch pipe, the hot gas inlet branch pipe and the hot gas outlet branc...

specific Embodiment 2

[0054] When the two towers of adsorption tower B2 and adsorption tower C3 are adsorbed and dehydrated, the adsorption tower D4 is cold-regenerated, the adsorption tower A1 is hot-regenerated, and the adsorption tower E5 is standby. At this time, the adsorption tower B2 and the adsorption tower C3 are two dehydration towers, and the adsorption tower D4 is Cold regeneration tower and adsorption tower A1 are hot regeneration towers, and adsorption tower E5 is a standby tower;

[0055] Open the valves on the dehydration inlet branch pipe and the dehydration gas outlet branch pipe on the adsorption tower B2 and the adsorption tower C3, and close the valves on the cooling gas inlet branch pipe, the cooling gas outlet branch pipe, the hot gas inlet branch pipe and the hot gas outlet branch pipe;

[0056] Open the valve on the cooling gas inlet branch pipe and the cooling gas outlet branch pipe on the adsorption tower D4, and close the valves on the dehydration inlet branch pipe, the d...

specific Embodiment 3

[0061] When the two towers of adsorption tower C3 and adsorption tower D4 are adsorbed and dehydrated, the adsorption tower A1 is cold regenerated, the adsorption tower B2 is hot regenerated, and the adsorption tower E5 is used for standby; at this time, the adsorption tower C3 and the adsorption tower D4 are two dehydration towers, and the adsorption tower A1 is a cold regeneration tower, adsorption tower B2 is a hot regeneration tower, and adsorption tower E5 is a standby tower;

[0062] Open the valves on the dehydration inlet branch pipe and the dehydration gas outlet branch pipe on the adsorption tower C3 and the adsorption tower D4, and close the valves on the cooling gas inlet branch pipe, the cooling gas outlet branch pipe, the hot gas inlet branch pipe and the hot gas outlet branch pipe;

[0063] Open the valves on the cooling gas inlet branch pipe and the cooling gas outlet branch pipe on the adsorption tower A1, and close the valves on the dehydration inlet branch pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com