A refining method and device for esterification synthesis of n-propyl acetate

A technology of n-propyl ester and refining method, which is applied in the preparation of organic compounds, carboxylic acid ester preparation, chemical instruments and methods, etc., which can solve the problems of complex extraction and separation process steps, difficult rectification and separation, and low purity of products , to achieve the effects of improving energy utilization, reducing the types of azeotropes, and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

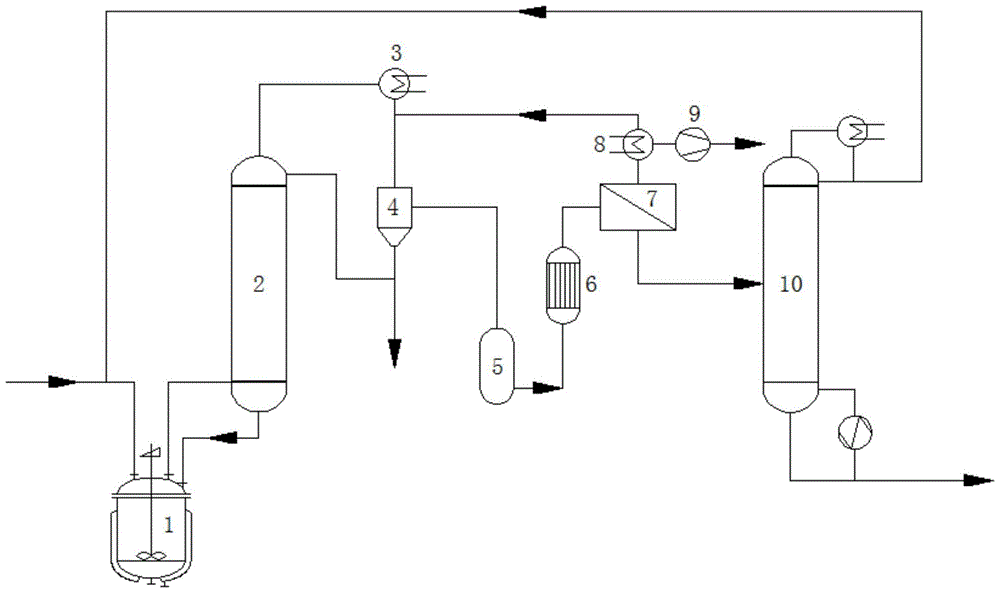

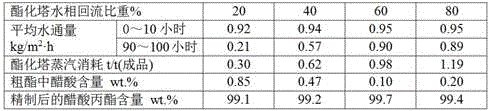

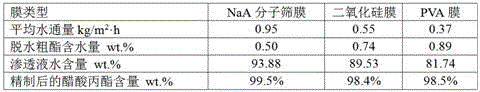

[0056] The refining method of n-propyl acetate esterification synthesis, the device used is as figure 1 As shown, the operation process comprises the following steps: the crude product obtained by the esterification tank is sent to the esterification tower from the bottom of the tower in the vapor phase, and the n-propyl acetate is initially separated by rectification in the esterification tower, and the unreacted The raw materials are returned to the esterification tank from the bottom of the esterification tower to continue the reaction, and the crude ester composed of n-propyl acetate, water, and part of n-propanol is evaporated from the top of the esterification tower. In the above process, the amount of catalyst used is 0.5% of the weight percentage of the raw material acetic acid, the molar ratio of the raw material acetic acid and propanol is 1.5:1, and the temperature is controlled at 60°C; when the equilibrium of the esterification tower is established, the temperature...

Embodiment 2

[0062] The refining method of n-propyl acetate esterification synthesis, the device used is as figure 1 As shown, the operation process comprises the following steps: the crude product obtained by the esterification tank is sent to the esterification tower from the bottom of the tower in the vapor phase, and the n-propyl acetate is initially separated by rectification in the esterification tower, and the unreacted The raw material returns to the esterification kettle from the bottom of the esterification tower to continue the reaction, and the crude ester composed of n-propyl acetate, water, and part of n-propanol is steamed from the top of the esterification tower; 0.5%, the molar ratio of raw materials acetic acid and propanol is 1.5:1, and the temperature is controlled at 60°C; when the equilibrium of the esterification tower is established, the temperature of the tower bottom is controlled at 105°C, and the gas phase temperature at the top of the tower is 85°C. After being...

Embodiment 3

[0068] The refining method of n-propyl acetate esterification synthesis, the device used is as figure 1 As shown, the operation process comprises the following steps: the crude product obtained by the esterification tank is sent to the esterification tower from the bottom of the tower in the vapor phase, and the n-propyl acetate is initially separated by rectification in the esterification tower, and the unreacted The raw material returns to the esterification kettle from the bottom of the esterification tower to continue the reaction, and the crude ester composed of n-propyl acetate, water, and part of n-propanol is steamed from the top of the esterification tower; 0.5%, the molar ratio of raw materials acetic acid and propanol is 1.5:1, and the temperature is controlled at 60°C; when the equilibrium of the esterification tower is established, the temperature of the tower bottom is controlled at 105°C, and the gas phase temperature at the top of the tower is 85°C. After being...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com