Device and method for dehydrating and dehumidifying wellhead natural gas

A technology for natural gas and natural gas pipelines, which is applied in the direction of gas fuel, earthwork drilling, wellbore/well components, etc. It can solve the problems of a large amount of external energy input, affect the dehydration effect, and absorb solvent failure, so as not to be affected by seasons and temperature fluctuations , wide application range and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0022] The present invention provides a wellhead natural gas dehydration and dehumidification device and method to solve the problems of complex process flow, high equipment investment cost and high energy consumption during operation faced by the existing wellhead natural gas dehydration and dehumidification process.

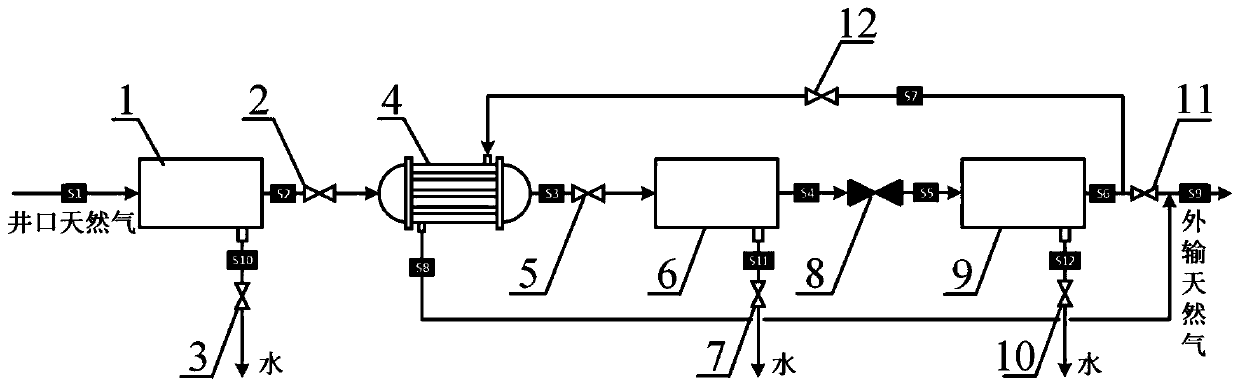

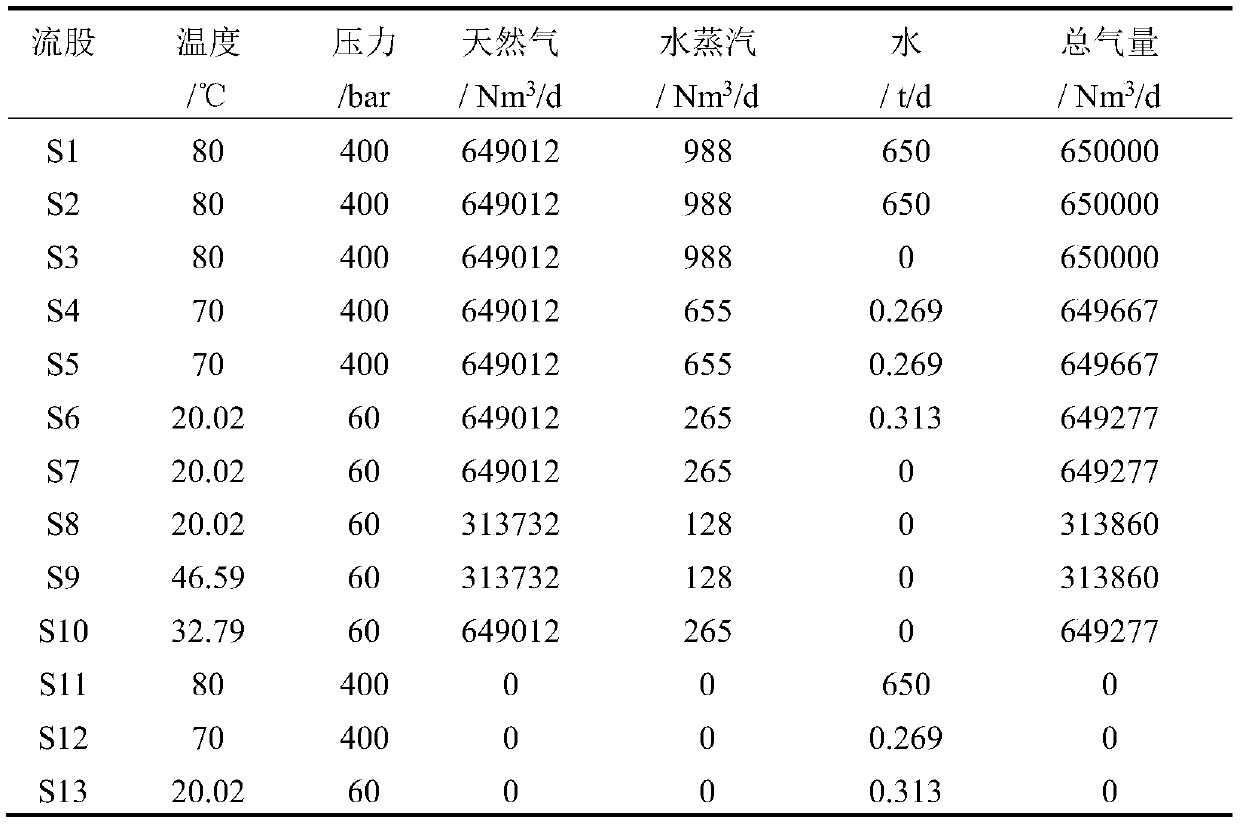

[0023] The device includes a gas-liquid pre-separator 1, a heat exchanger 4, a primary gas-liquid separator 6, a throttling tube 8, a final gas-liquid separator 9 and control valves on each pipeline;

[0024] The input end of the gas-liquid pre-separator 1 is connected to the wellhead natural gas pipeline, the gas output end of the gas-liquid pre-separator 1 is connected to the hot fluid input end of the heat exchanger 4, and the liquid ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com