Hydrocarbon injection dewaxing device and technology suitable for dehydration and hydrocarbon removal of wax-containing natural gas

A natural gas and hydrocarbon removal technology, applied in the petroleum industry, gas fuel, fuel, etc., to achieve the effect of avoiding clogging and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

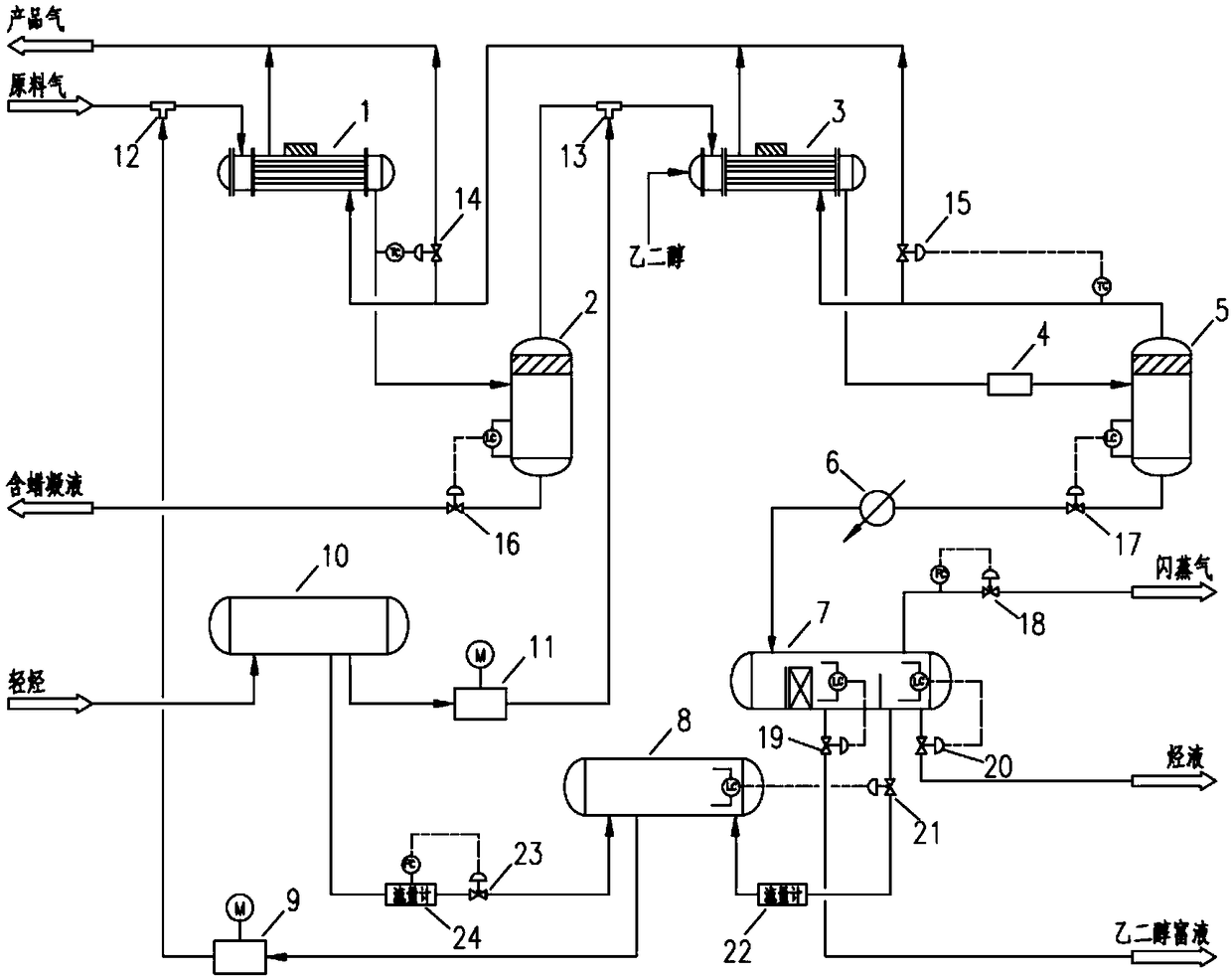

[0018] A hydrocarbon injection dewaxing device suitable for dehydration and dehydrocarbonation of waxy natural gas, such as figure 1 As shown, it includes: feed gas precooler 1, feed gas separator 2, feed gas aftercooler 3, refrigeration facility 4, low temperature separator 5, heater 6, three-phase separator 7, hydrocarbon liquid storage tank 8, Hydrocarbon liquid injection pump 9, light hydrocarbon storage tank 10 and light hydrocarbon injection pump 11, hydrocarbon liquid atomizer 12, light hydrocarbon atomizer 13, feed gas precooler shell side bypass regulating valve 14, feed gas aftercooler Shell side bypass regulating valve 15, raw material gas separator liquid level regulating valve 16, low temperature separator liquid level regulating valve 17, three-phase separator pressure regulating valve 18, three-phase separator water phase liquid level regulating valve 19, three-phase Separator oil phase liquid level regulating valve 20, hydrocarbon liquid storage tank liquid lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com