Natural gas dewatering system for using waste heat of molecular sieve regenerated gas

A technology for regenerating gas and natural gas, applied in the field of natural gas liquefaction, can solve the problems of wasting energy, consuming fuel gas, and consuming water and electricity in heating and cooling of regenerative gas, so as to reduce flue gas emissions, reduce operating costs, and save operating costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

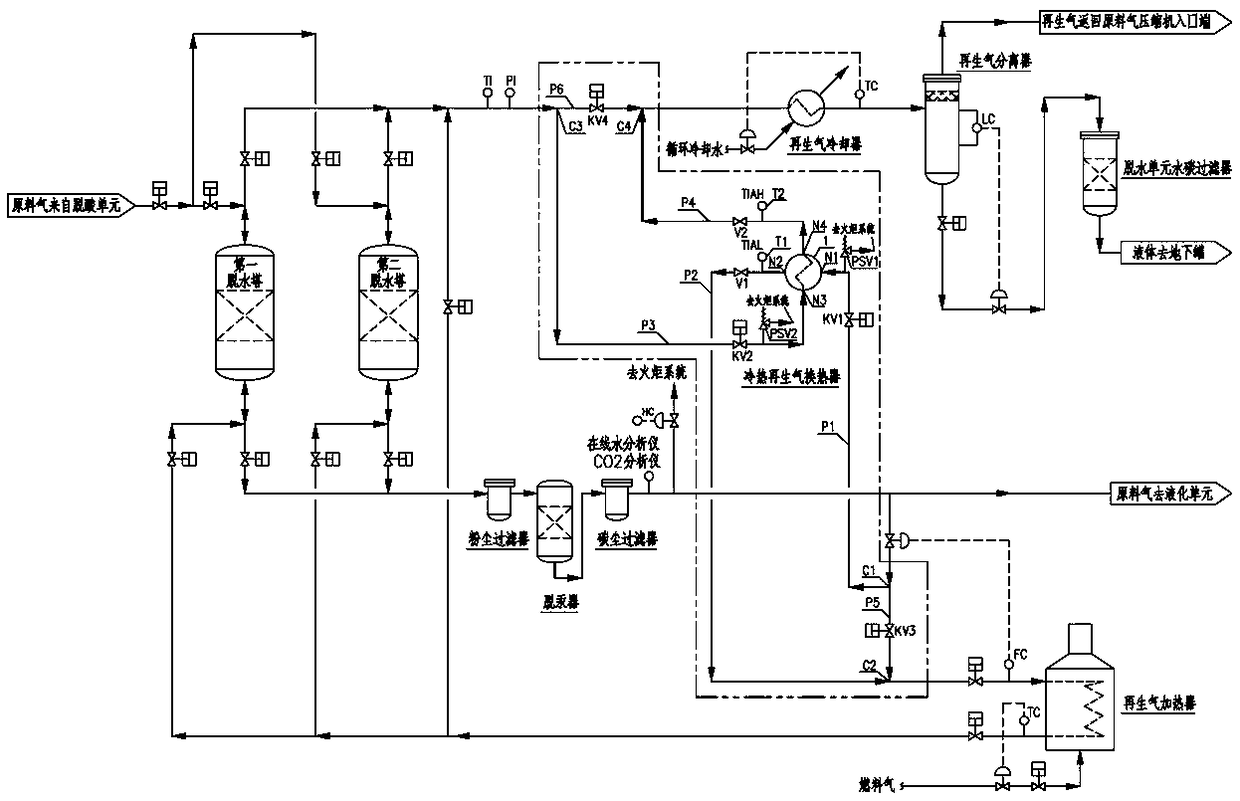

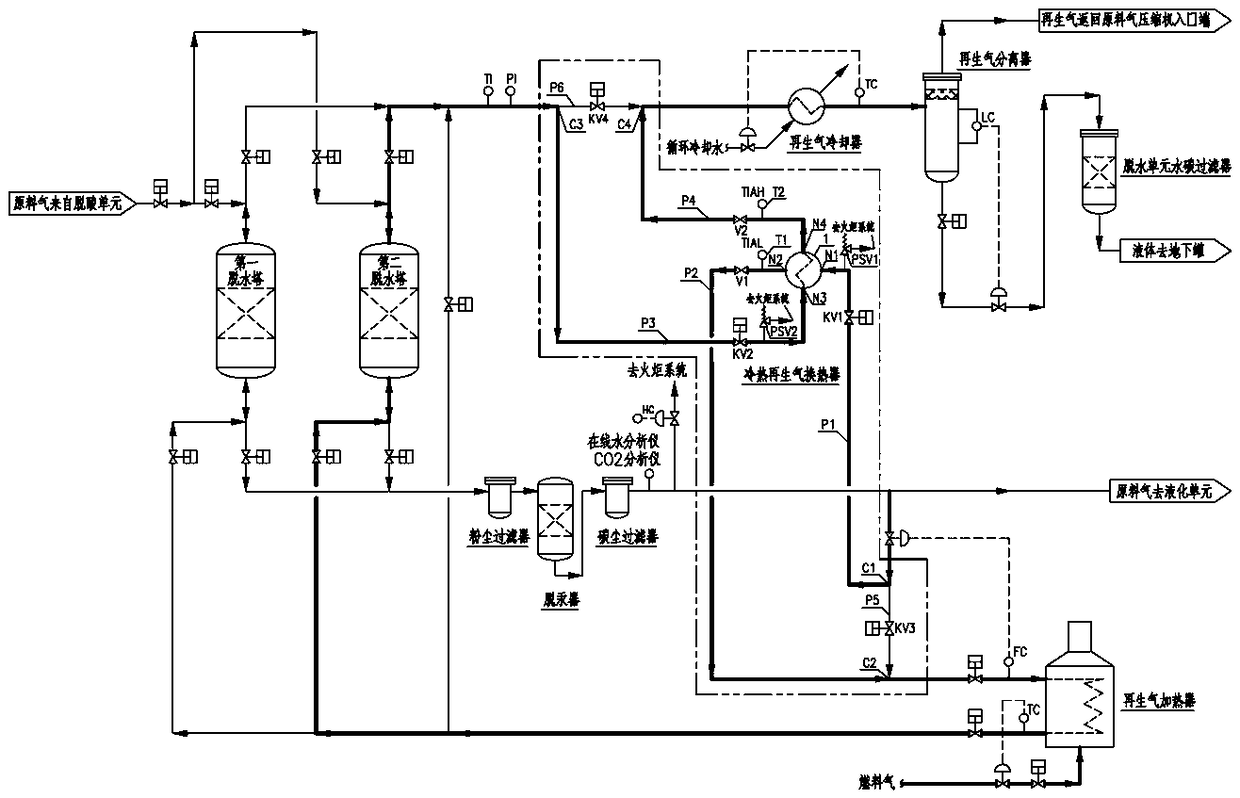

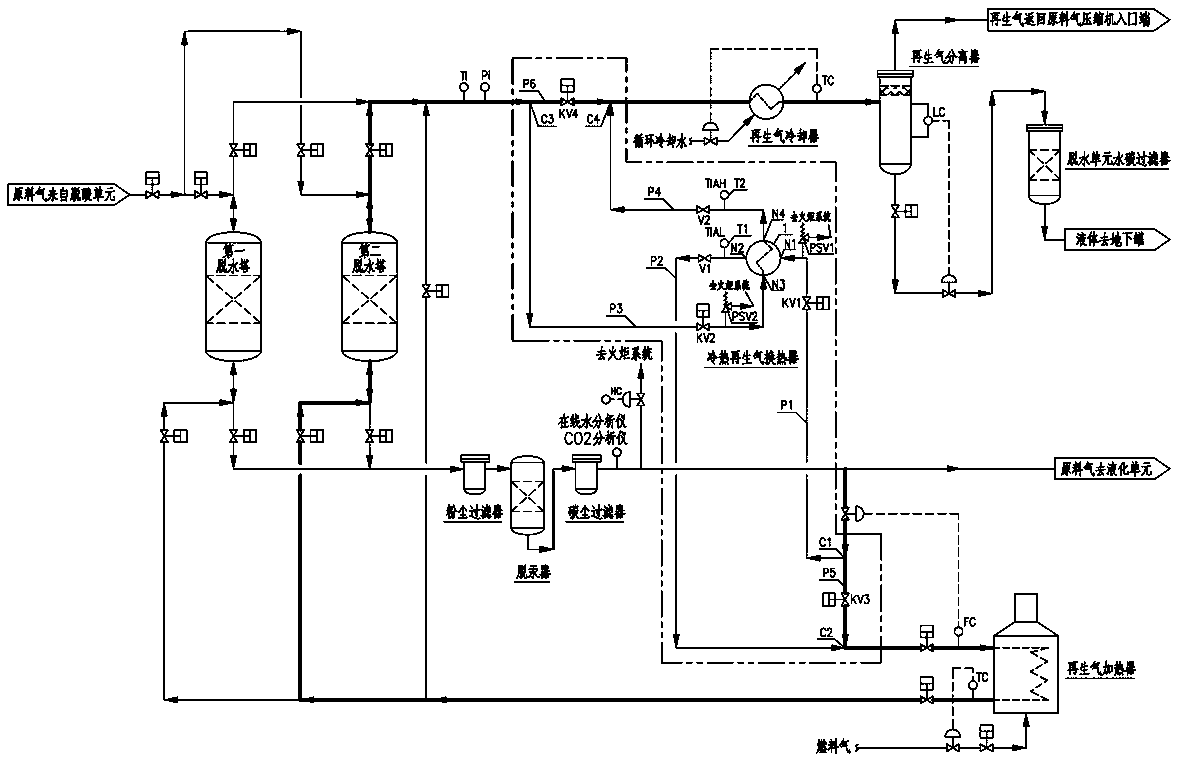

[0034] see figure 1 , a natural gas dehydration system with molecular sieve regeneration gas waste heat utilization includes a first dehydration tower, a second dehydration tower, a dust filter, a mercury remover, a carbon dust filter, a regeneration gas heater, a regeneration gas cooler, and a regeneration gas separation device and dehydration unit water carbon filter; the first dehydration tower and the second dehydration tower are connected in parallel; the regeneration gas cooler, regeneration gas separator and dehydration unit water carbon filter are sequentially connected in series at the top of the first dehydration tower The regenerated gas outlet and the regenerated gas outlet at the top of the second dehydration tower; the dust filter, the mercury remover and the carbon dust filter are sequentially connected in series with the bottom outlet of the first dehydration tower and the bottom outlet of the second dehydration tower; The outlet of the regenerative gas heater ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com