Natural gas multi-tower external cycle anaerobic regeneration dewatering method

A technology of natural gas and external circulation, which is applied in the fields of natural gas dehydration and natural gas purification in oilfields. It can solve the problems of increased resistance of the dehydration system, decreased dehydration efficiency, and increased economic costs, and achieves the effects of reducing energy consumption, saving operating costs, and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

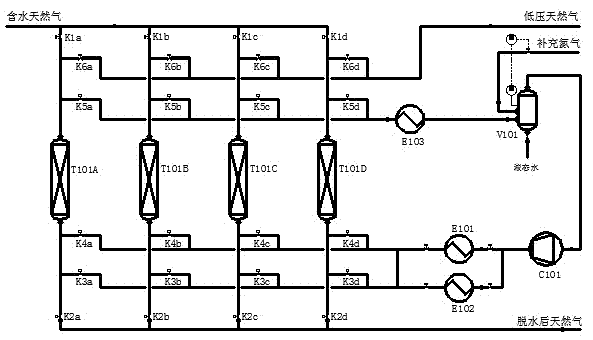

[0024] see figure 1 , for the convenience of description, the following four adsorption towers T101A~D are taken as an example to illustrate the present invention. Among them, the adsorption tower T101A and the adsorption tower T101B are in the adsorption process, the adsorption tower T101C is in the heating process, and the adsorption tower T101D is in the cooling process.

[0025] Adsorption process

[0026] This embodiment adopts double-tower parallel adsorption, that is, there are two towers in the adsorption step at any time, and the feeding time of the two towers differs by half an adsorption cycle.

[0027] Raw natural gas (including saturated water) enters from the top of adsorption towers T101A and T101B through valves K1a and K1b at room temperature, and comes out from the bottom of adsorption towers T101A and T101B through valves K2a and K2b, and is sent outside the boundary through valves K2a and K2b. During this process, the raw material gas water, heavy hydroca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com