Hypergravity-process triglycol natural gas dehydration system and process using system

A technology of triethylene glycol and natural gas, which is applied in gas fuel, petroleum industry, fuel and other directions, can solve the problems of large loss of triethylene glycol, large area of buffer tank, complicated process, etc., and achieves good absorption and mass transfer effect. Small footprint and high dehydration balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

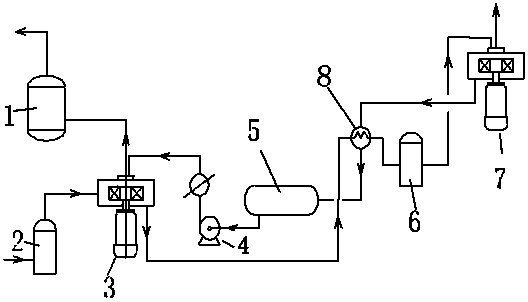

[0030] The technical process of the dehydration of TEG natural gas by the supergravity method of the present invention mainly includes the absorption and regeneration process, and the main equipment is a gas-liquid separator, a filter separator, an absorption supergravity machine, a flash tank, a regeneration supergravity machine and The composition of the buffer tank mainly includes the process of absorption and regeneration. The absorption process adopts a conventional external circulation supergravity machine, the regeneration process adopts an external circulation or internal circulation supergravity machine, the absorbent uses triethylene glycol absorbent (TEG), the operating pressure is 0-10Mpa, the temperature is 15-250℃, and the supergravity level is 10 -500g. The operation steps are as follows: the water-containing natural gas enters from the gas phase inlet of the supergravity machine, and contacts and reacts with the poor absorbent liquid entering the supergravity mac...

Embodiment 2

[0037] Use the device and process of embodiment 1 to carry out natural gas dehydration:

[0038] Capacity: 10m 3 / h, pressure 0.1MPa, water content in raw gas 25g / m 3 , triethylene glycol TEG as absorbent (concentration of poor solution is over 99%), the amount of TEG in the absorption solution is 0.5m 3 / h, the speed of absorption supergravity machine is 600r / min. After using this process, the dew point of the exported natural gas is below -15°C, the dehydration balance is above 95%, the concentration of rich liquid is about 95%, and the concentration of lean liquid after regeneration can reach above 99%.

Embodiment 3

[0040] As shown in Example 2, other conditions remain unchanged, and the speed of the absorption supergravity machine is adjusted to 800r / min. After using this process, the dew point of the exported natural gas is below -17°C, the degree of dehydration balance is above 95%, and the concentration of the rich liquid About 95%, after regeneration, the concentration of barren solution can reach more than 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com