De-heavy hydrocarbon apparatus and process for gas dehydration

A process method and technology for removing heavy hydrocarbons, which are applied in the petroleum industry, gas fuel, fuel and other directions to achieve the effect of saving construction period, facilitating transportation and installation, and saving heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

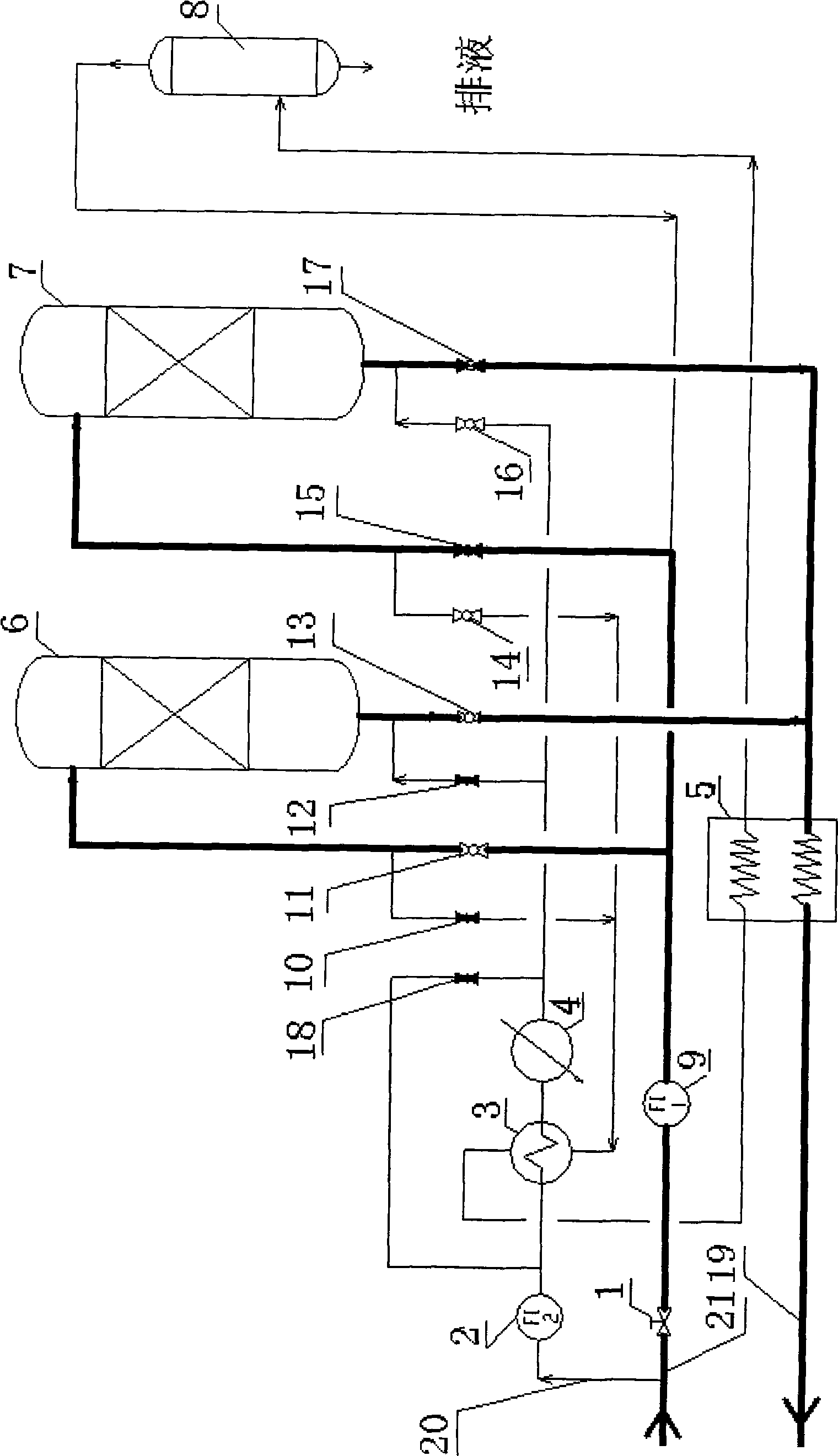

Image

Examples

example

[0029] Component molar composition Component molar composition Component molar composition C 1 91.934 iC 5 0.094 c 9 0.012 C 2 4.96 c 5 0.046 c 10 0.005 C 3 0.948 c 6 0.11 C 11+ 0.003 iC 4 0.172 c 7 0.104 CO 2 0.701 c 4 0.165 c 8 0.024 N 2 0.722

[0030] The water in it is saturated water.

Embodiment 1

[0032] ① The amount of activated alumina is 10 times the mass of the maximum saturated water in the gas;

[0033] ②13X molecular sieve, the dosage is 10 times of the total mass of C6~C8 heavy hydrocarbons and CO2 to be removed;

[0034] ③B-type silica gel, the specific surface area is about 420-500m2 2 / g, the average pore size is 3.5nm, and the particle size is 40 mesh; the dosage is 20 times of the total mass to be removed ≥C8+;

[0035] ④Mesoporous coal-based activated carbon AFX-II, the dosage is 20 times of the total mass of ≥C11+ to be removed.

Embodiment 2

[0037] ① The amount of activated alumina is 11 times the mass of the maximum saturated water in the gas;

[0038]②13X molecular sieve, the dosage is 12 times of the total mass of C6~C8 heavy hydrocarbons and CO2 to be removed;

[0039] ③B-type silica gel, the specific surface area is about 420-500m2 2 / g, the average pore size is 3.5nm, and the particle size is 40 mesh; the dosage is 25 times of the total mass to be removed ≥C8+;

[0040] ④Mesoporous coal-based activated carbon AFX-II, the dosage is 25 times the total mass of ≥C11+ to be removed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com