Comprehensive natural gas processing

a technology of natural gas processing and natural gas, applied in the direction of gaseous fuels, liquefaction, lighting and heating apparatus, etc., can solve the problems of high capital and operational costs, process is extremely energy-consuming, and global ng consumption may eventually exceed all other fossil fuels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

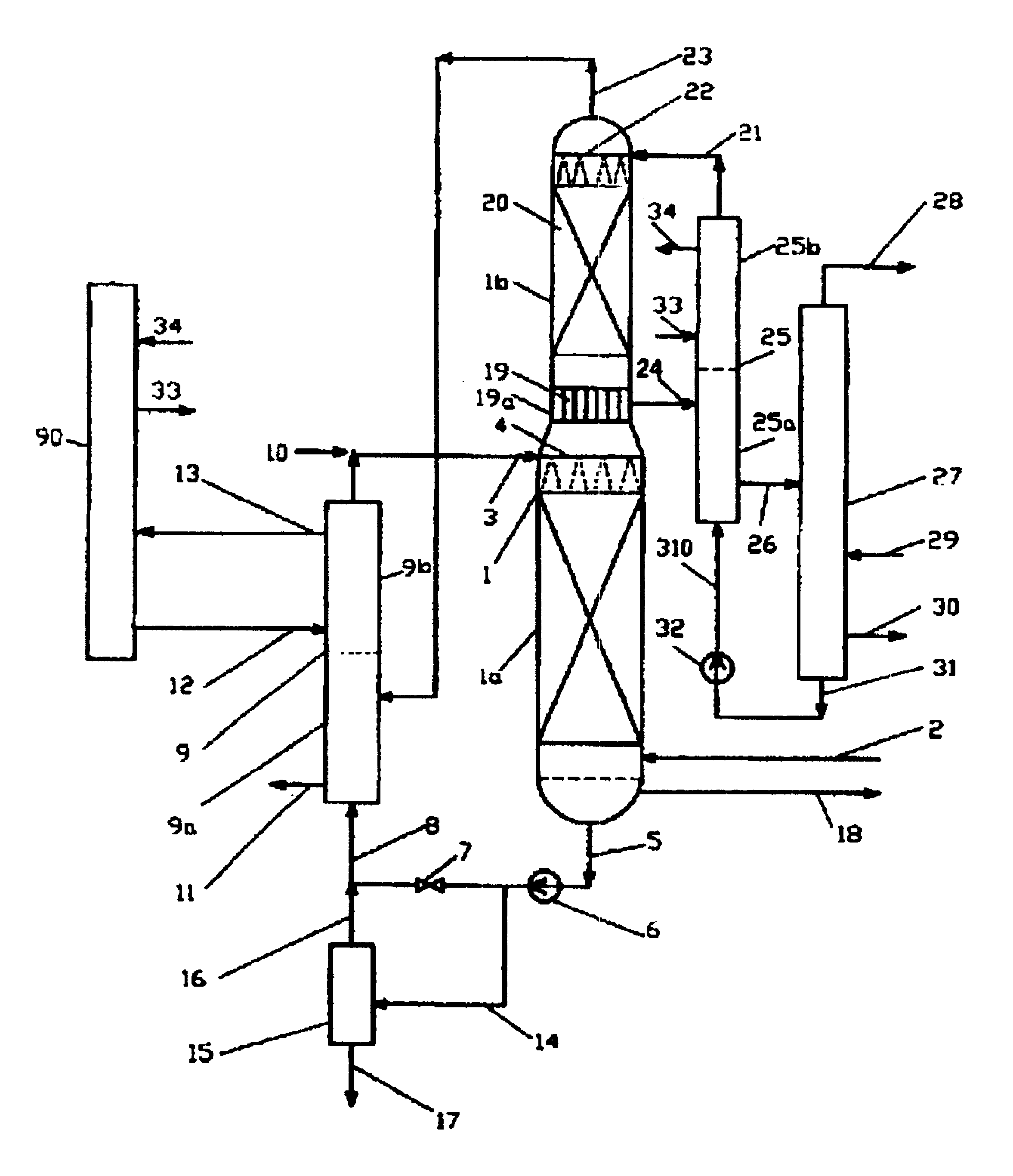

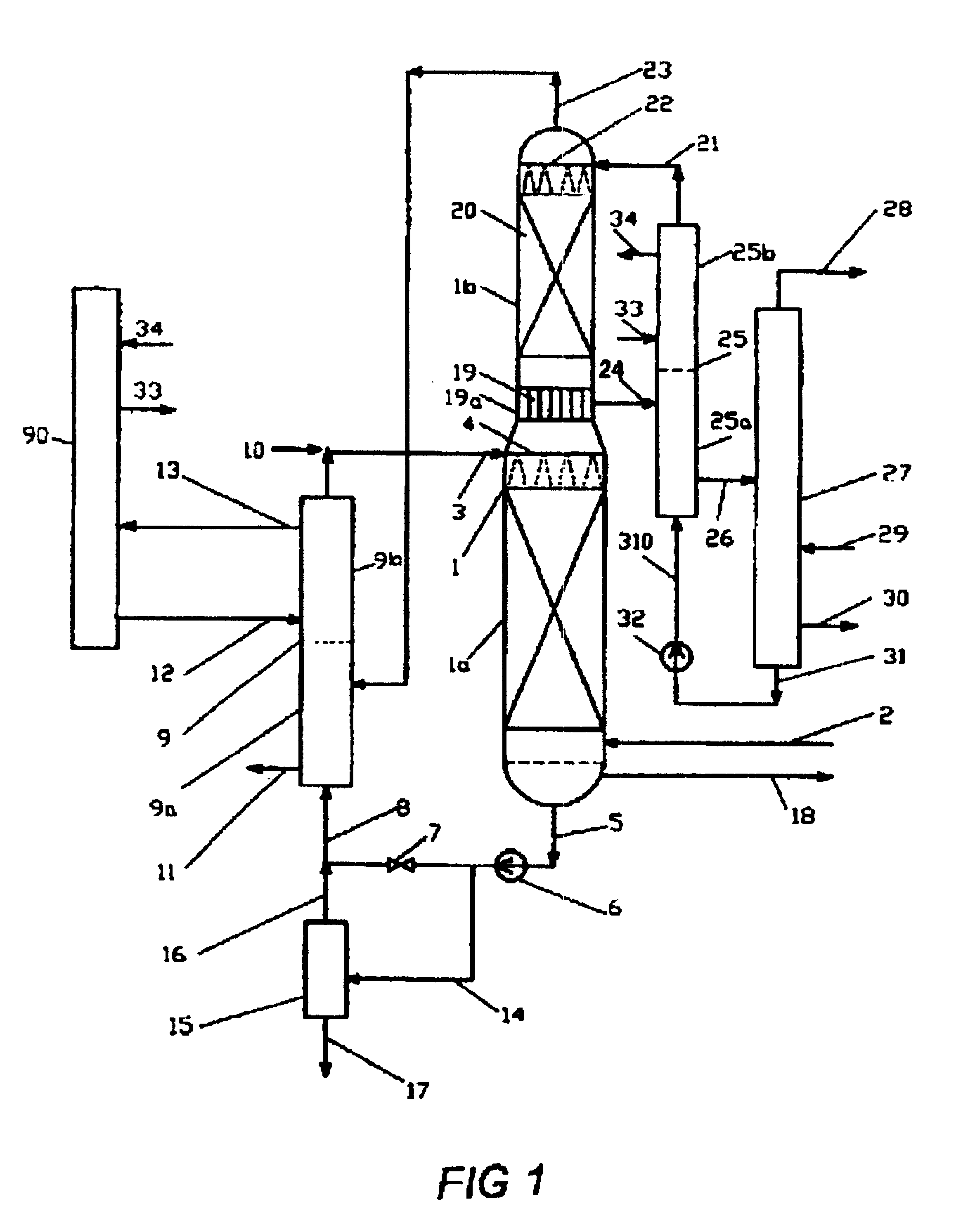

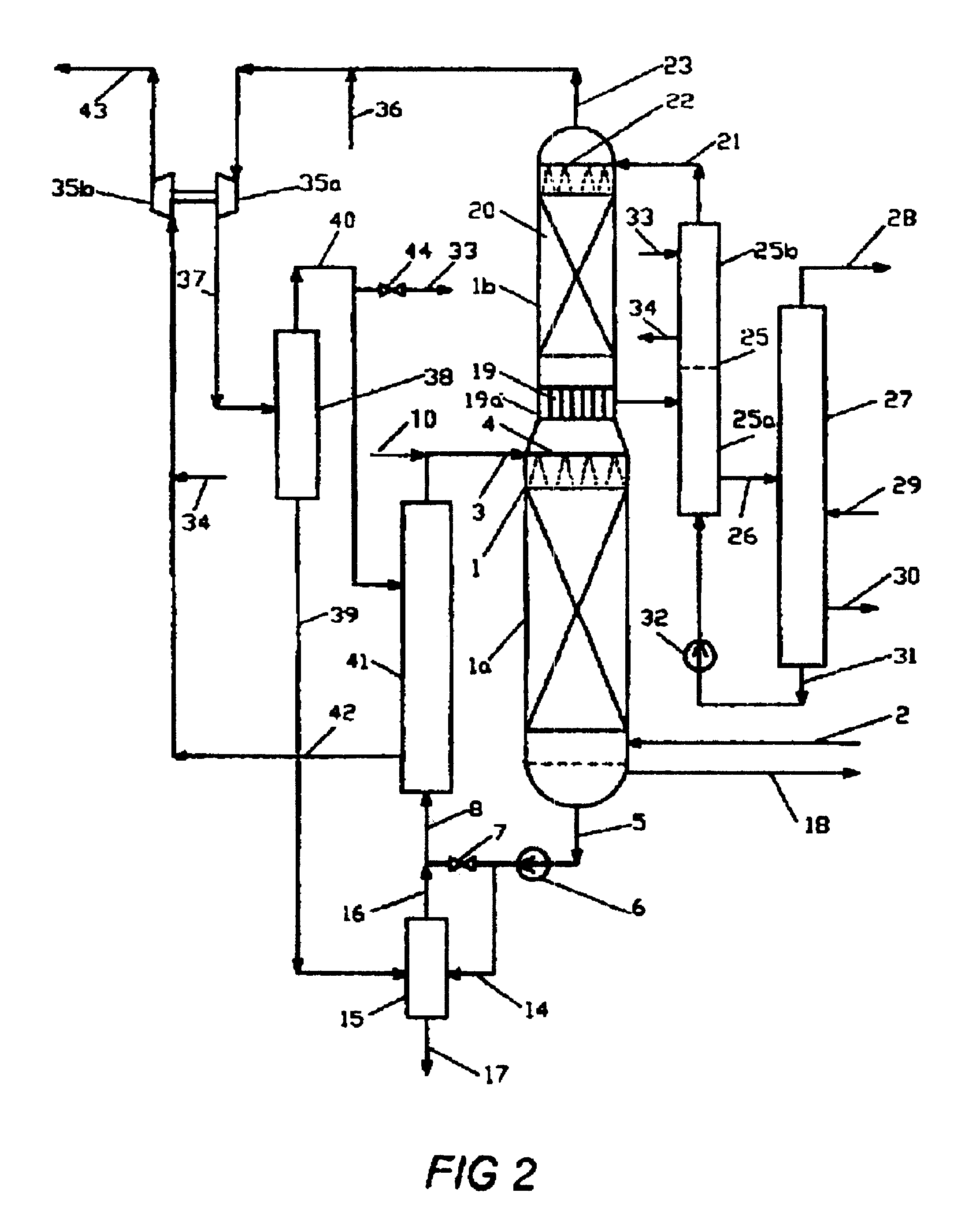

[0018]FIG. 1 illustrates one preferred embodiment of the comprehensive NG processorprocessing of the present invention wherein a separate industrial refrigeration unit is used to provide the required refrigeration.

[0019]The said apparatus comprises the following major components: a processor 1 comprising a dehydrator 1a and an absorber 1b; a medium cooler 9 comprising a pre-cooler 9a and a deep-cooler 9b; an absorbent cooler 25 comprising a pre-cooler 25a and a deep-cooler 25b; a fractional distiller 27; an inhibitor regenerator 15, and a refrigeration unit 90.

[0020]The inlet NG, laden with moisture and all the higher hydrocarbon components, i.e., C2, C3, C4, and C5+, enters the dehydrator 1a from the bottom via the raw NG inlet pipeline 2 and flows upward.

[0021]A low-temperature medium, containing an inhibitor, enters from the top of the dehydrator via the medium inlet pipeline 3. The medium is distributed or dispersed with the medium distributor 4 over the whole cross-section of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling points | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com