Tubular parallel flow type gas-liquid contact absorber

A gas-liquid contact and absorber technology, which is applied in gas fuel, chemical instruments and methods, petroleum industry, etc., can solve the problems of poor particle size uniformity, low efficiency and large atomization pressure difference of atomized micro-droplets. Achieve the effect of high gas-liquid mass transfer efficiency, wide adaptability and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0025] The preferred embodiment of the tubular parallel-flow gas-liquid contact absorber of the present invention is:

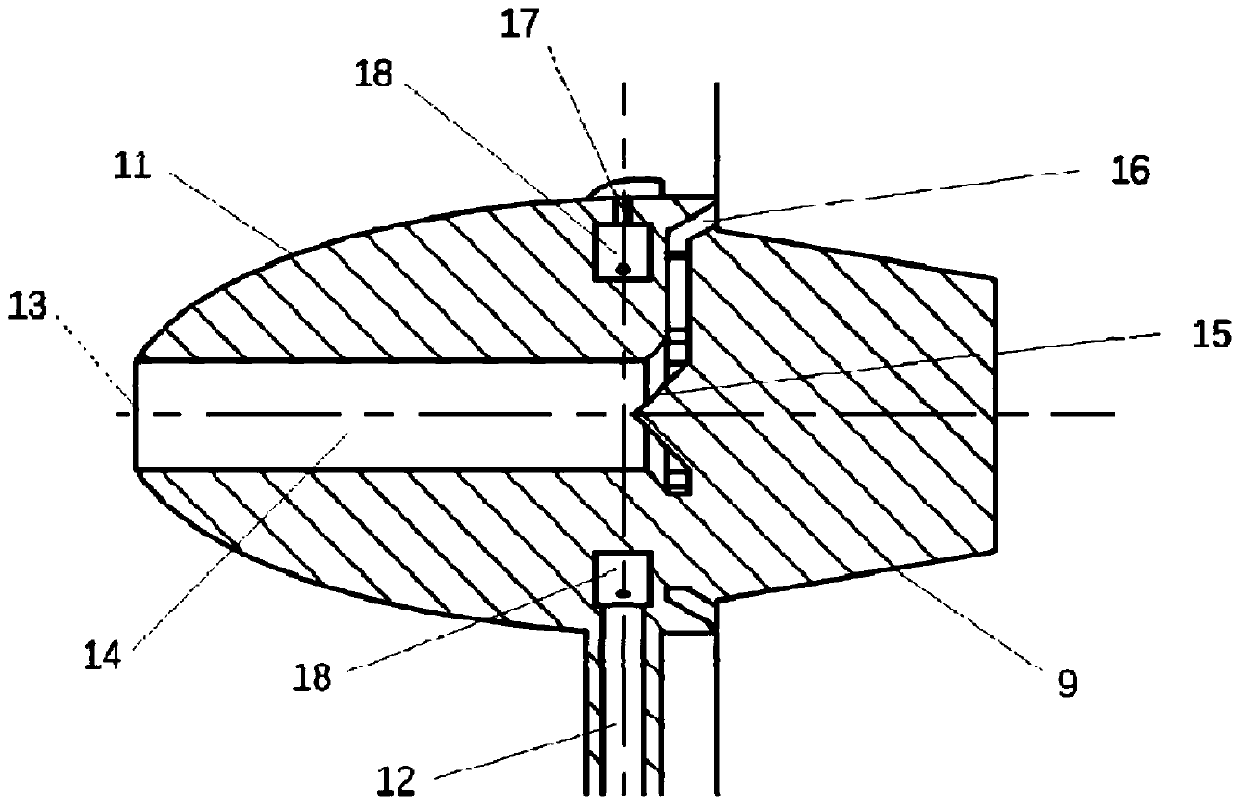

[0026] From the perspective of functional division, it mainly includes a gas steady flow straight pipe section, a gas shrinkage acceleration section, a gas dispersion expansion section, and a gas-liquid uniform mixing mass transfer absorption section connected in sequence. The gas shrinkage acceleration section and the gas dispersion expansion section are equipped with liquid absorption. The agent is injected into the atomization part, and the liquid absorbent injection atomization part includes a built-in ellipsoidal diversion cone and a trapezoidal cone;

[0027] The gas steady flow straight pipe section is a straight pipe from the absorber inlet to the gas shrinkage acceleration section;

[0028] The structure of the gas shrinkage acceleration section is a gas channel with a tapered flow area composed of an inner cone with a tapered diameter and an outer w...

specific Embodiment

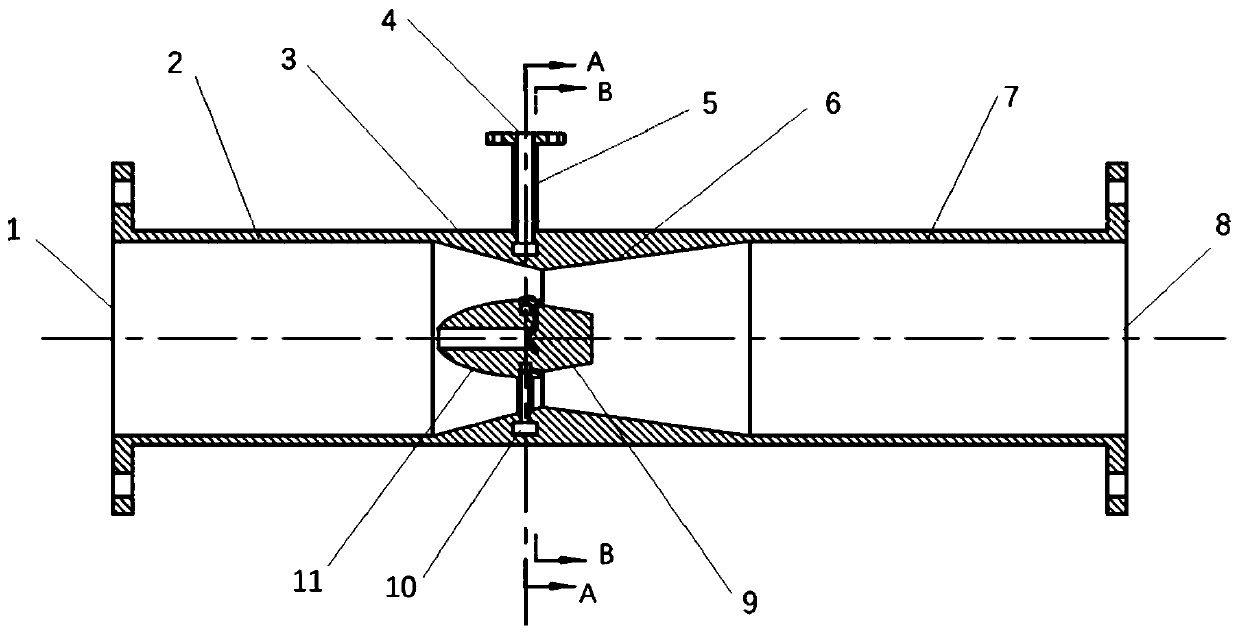

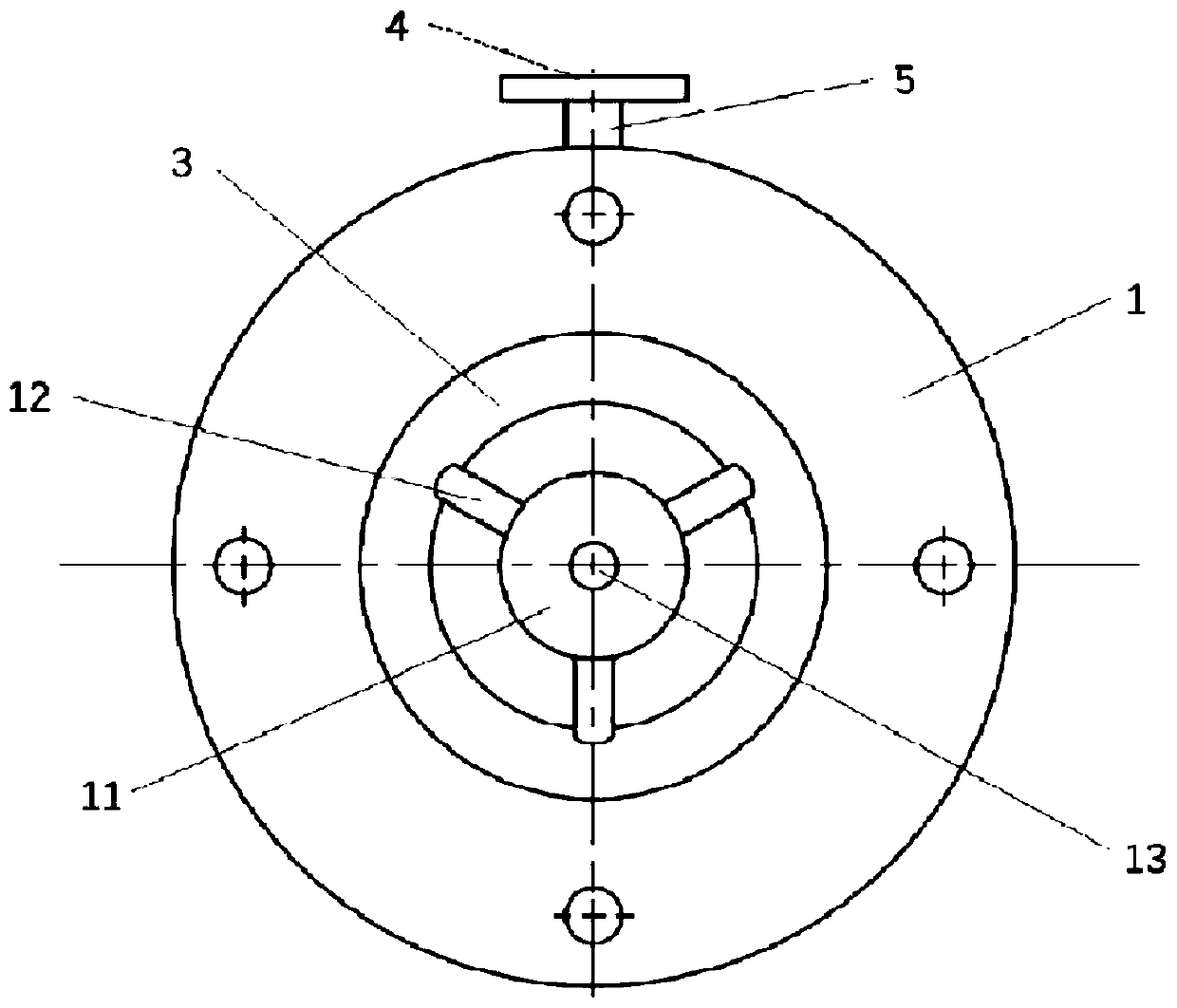

[0048] Such as Figure 1 to Figure 5 As shown, the embodiment of the present invention provides a tubular co-current gas-liquid contact absorber. The outer tube of the contact absorber includes the gas inlet 1 of the absorber, the gas steady flow straight pipe section 2, and the inner cone 3 with tapered diameter. , inner cone 6 with gradually expanding diameter and gas-liquid mixed mass transfer straight pipe section 7. The tubular parallel-flow gas-liquid contact absorber is connected to the gas upstream process pipeline by means of flanges or welding, the gas inlet 1 of the tubular parallel-flow gas-liquid contact absorber is connected to the inner cone 3 with tapered diameter of the outer pipe The circular pipe part between is the gas steady flow straight pipe section 2, and the gas steady flow straight pipe section 2 is connected with the gas shrinkage acceleration section, and the gas shrinkage acceleration section is the inner wall of the outer pipe diameter tapered inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com