Device and process applied to reinforced absorption of methyl iodide in acetic acid tail gas

A technology for strengthening absorption and acetic acid, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of restricting the CO separation and purification process, increasing the production cost of acetic acid, wasting energy, etc., and achieving safe, stable and reliable production. Simple, Productive Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

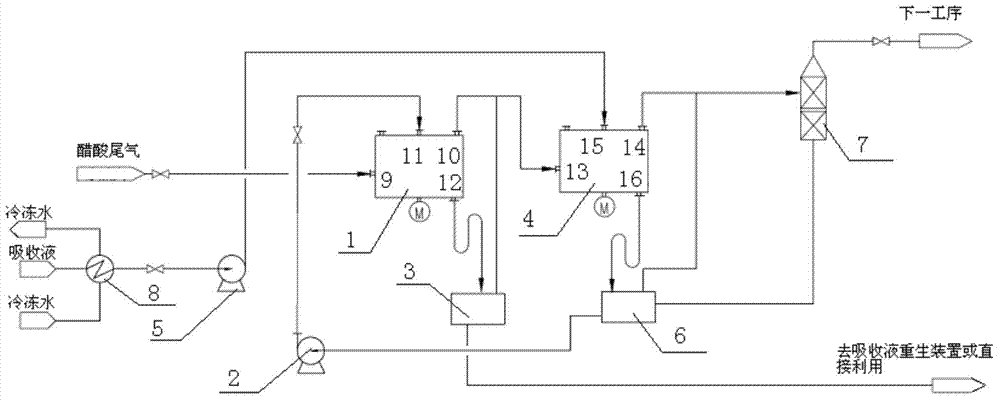

[0018] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0019] figure 1 It is a schematic diagram of the overall structure of the present invention, such as figure 1 Shown: the present invention comprises two strengthened absorption equipments, is respectively primary strengthened absorption equipment 1 and secondary strengthened absorption equipment 4, two strengthened absorption equipments are connected in series, the present invention also comprises primary absorption liquid pump 2, a Primary absorption liquid storage tank 3 , secondary absorption liquid pump 5 , secondary absorption liquid storage tank 6 , demister 7 and absorption liquid cooler 8 .

[0020] The air inlet 9 of the primary enhanced absorption equipment 1 communicates with the source of acetic acid tail gas, the gas outlet 10 of the primary enhanced absorption equipment 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com