A kind of enhanced micro-bubble hedging type VOCs spray reaction device

A reaction device, hedging technology, applied in the direction of gas treatment, air quality improvement, chemical instruments and methods, etc., can solve the problems of low internal gas-liquid mass transfer efficiency, large volume, internal packing blockage, etc., to improve system flexibility , Reduction of reactor height and improvement of mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention can be better understood from the following examples.

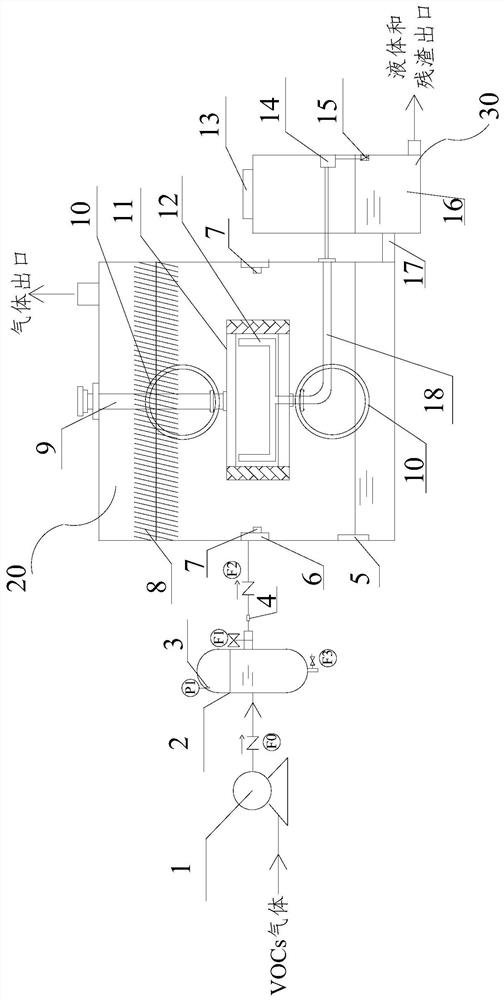

[0030] like figure 1 As shown, the enhanced micro-bubble counteracting VOCs spray reaction device of the present invention includes a fan 1 , a dissolved gas tank 2 , a spray reactor 20 and a chemical tank 30 .

[0031] Wherein, the blower 1 , the dissolved air tank 2 and the spray reactor 20 are connected by pipelines in sequence, and the VOCs waste gas to be treated is sent into the spray reactor 20 .

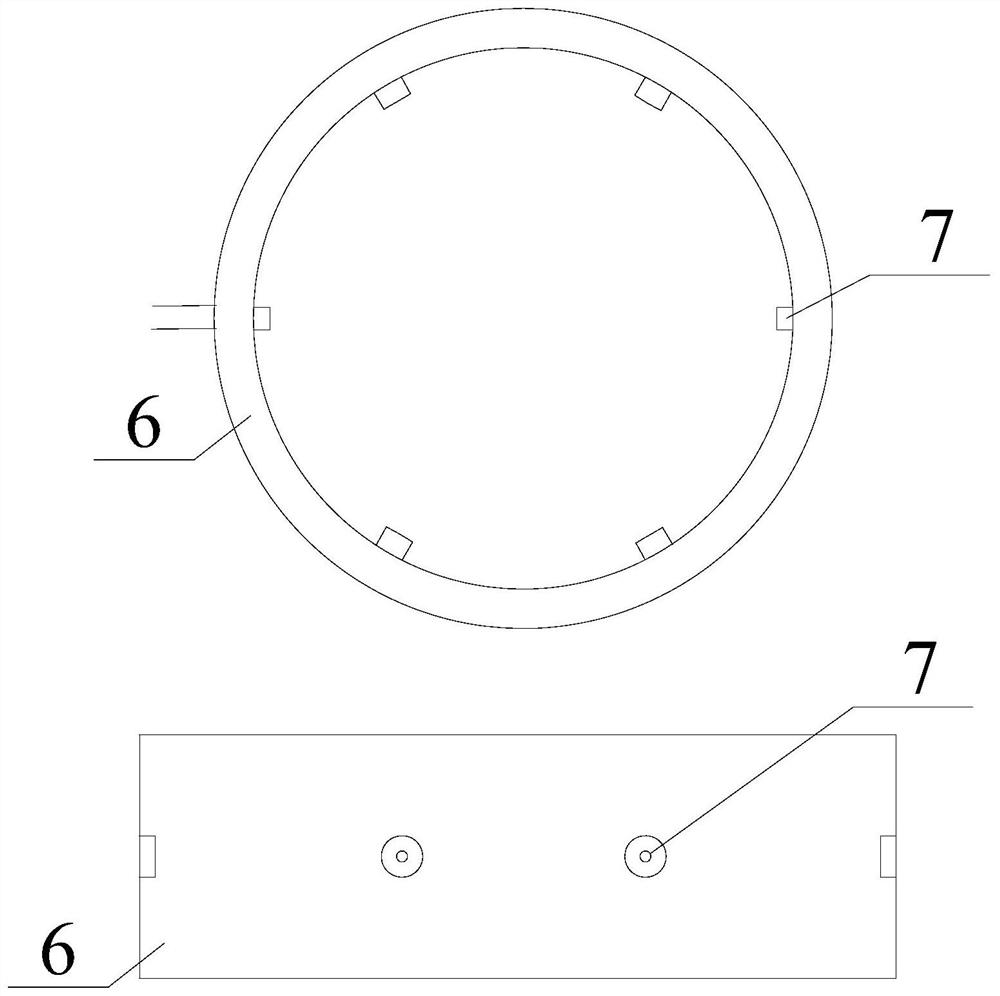

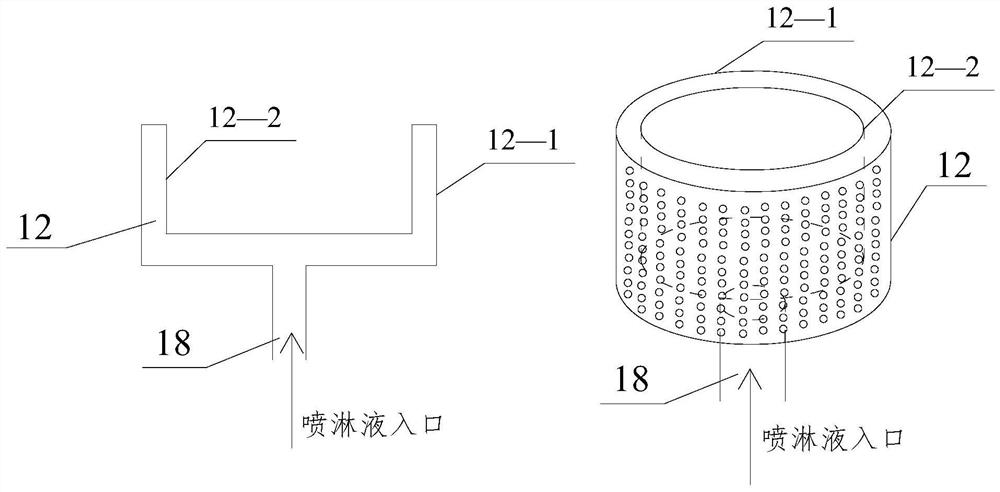

[0032] Inside the spray reactor 20, there is a rotating drum 11. The rotating drum 11 is connected to an external drive motor through the rotating shaft 9, and the rotating drum 11 is driven by the driving motor to rotate inside the spray reactor 20; the rotating drum 11 is provided with a liquid Distributor 12, the medicine tank 30 is connected to the liquid distributor 12 through the water distribution pipe 18, and the medicine in the medicine tank 30 is evenly distributed in the drum 11 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com