Air supersonic-velocity condensation and cyclone separation spray pipe

A swirl separation and supersonic technology, applied in the direction of gas fuel, separation method, dispersed particle separation, etc., can solve the problems of large fluid flow loss, increased processing capacity, large pressure loss, etc., to strengthen and stabilize swirl, improve Separation efficiency and high swirling ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The structural features and working principles of the present invention will be further described below in conjunction with the accompanying drawings.

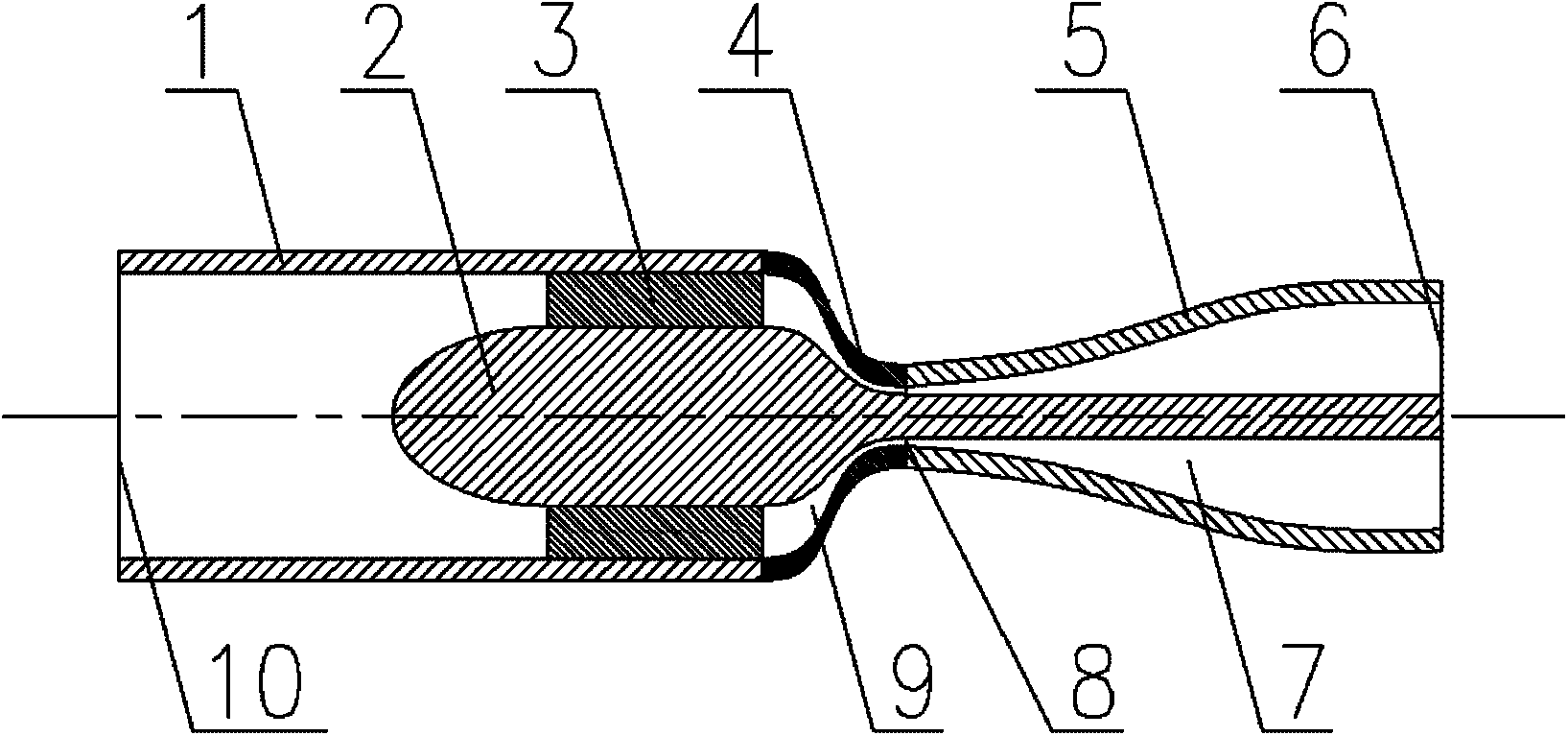

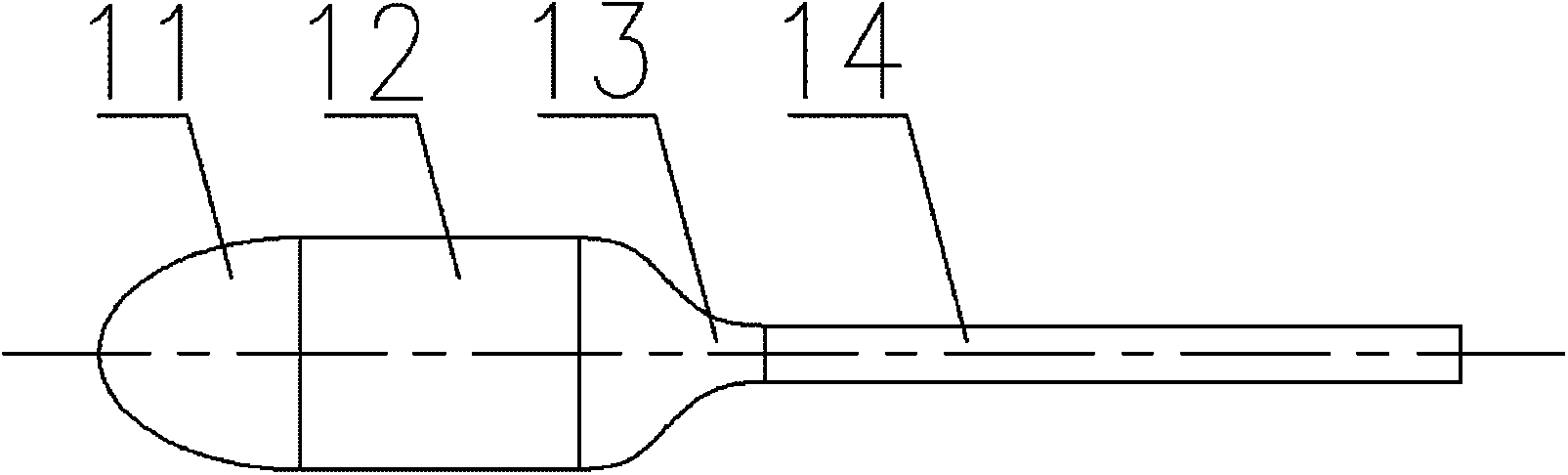

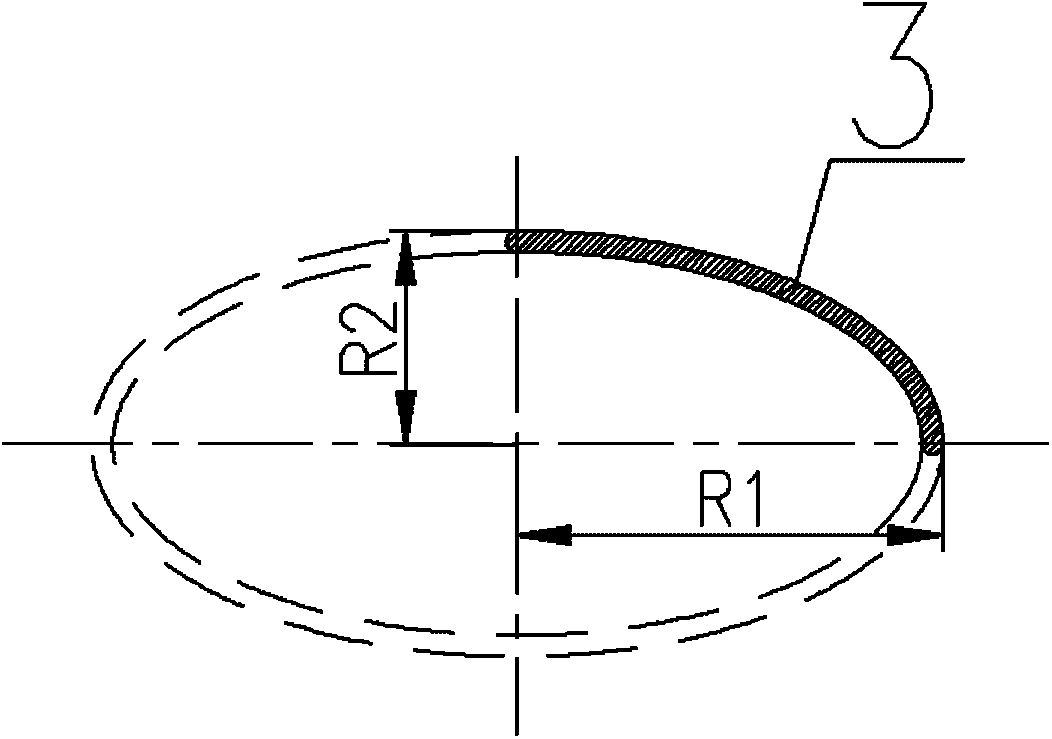

[0025] Such as figure 1 , figure 2 with image 3 As shown, the present invention is mainly composed of a straight pipe section 1, a central body 2, swirl vanes 3, a contraction section 4, an expansion section 5, an inlet 10 and an outlet 6; - Expansion of the nozzle to form a subsonic contraction channel 9, a throat 8 and a supersonic expansion channel 7; the upper end of the swirl vane 3 is fixedly connected to the inner wall of the straight pipe section 1, and the lower end is fixedly connected to the surface of the central body 2.

[0026] Such as figure 1 As shown, the shrinkage section 4 of the present invention is a tapered structure, and its contour curve is designed according to the following curve equation:

[0027] D x = D cr ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com