A two-petal submerged nozzle electromagnetic swirling device and its supporting device

A technology of swirl device and support device, which is applied to casting melt containers, manufacturing tools, metal processing equipment, etc., can solve the problems of inconvenient on-site continuous casting operation, interruption of swirl effect, low magnetic field efficiency, etc., to ensure smooth operation. , The effect of controlling the flow of molten steel and high utilization of the magnetic field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

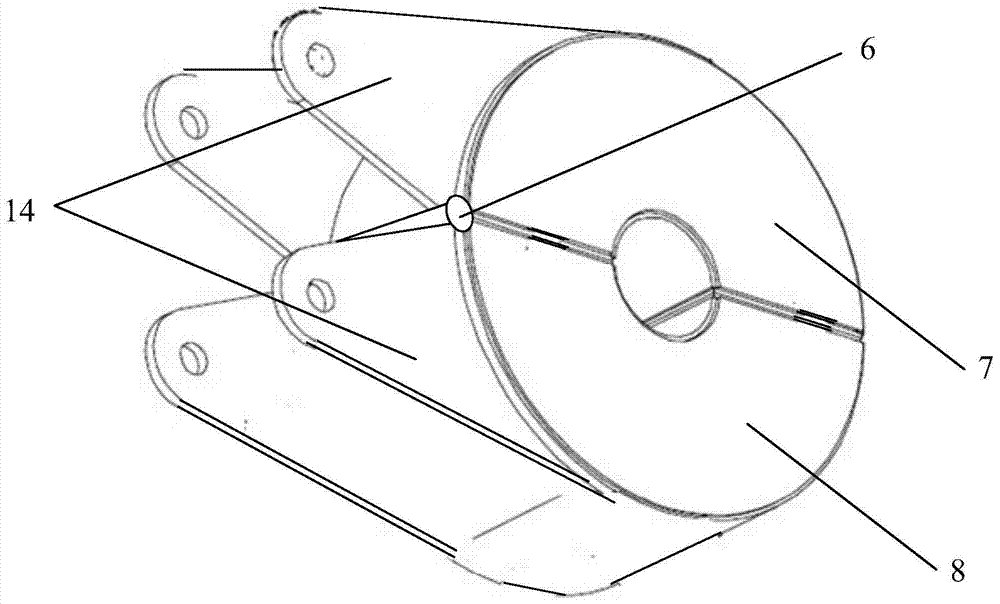

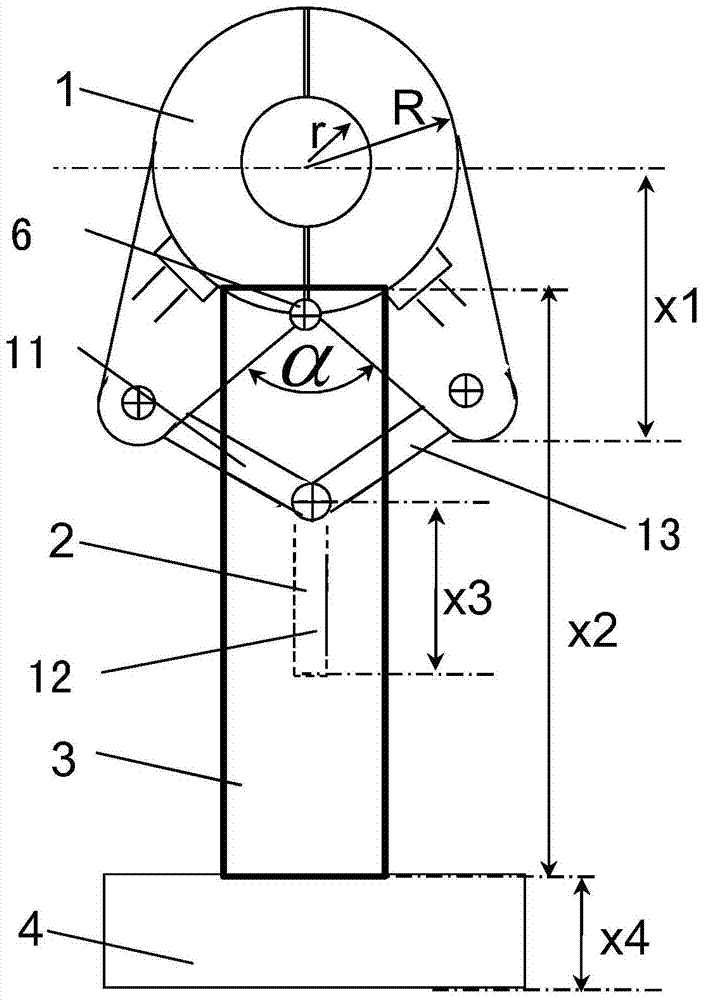

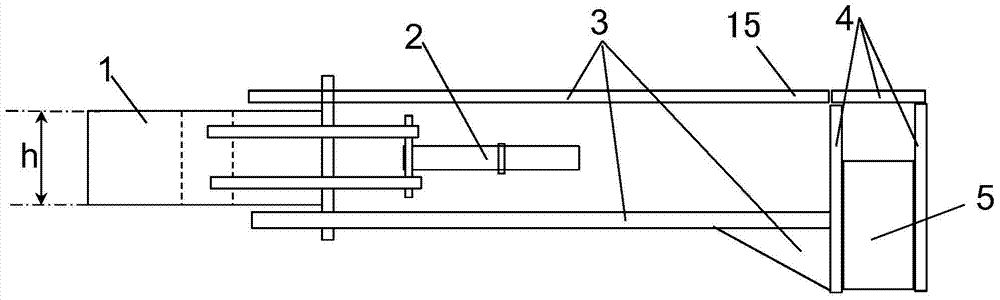

Embodiment 1

[0032]In this embodiment, the power cabinet can provide 8Hz, 1000A current, which can make the magnetic field rotate clockwise. The winding in the body 1 of the electromagnetic swirl device adopts the cogging type centralized winding. The height h of the body 1 of the electromagnetic swirl device is 80mm, the inner diameter r is 25mm, the outer diameter R is 80mm, and the opening and closing angle α is 10°. The distance x1 from the center of the electromagnetic swirl device body 1 to the lowermost end of the ear plate 14 is 100 mm. The opening and closing control mechanism 2 adopts a pneumatic method, and the length x3 of the control end of the opening and closing control mechanism 2 is 200mm. The support rod 15 is a telescopic structure, which is driven by pneumatic means, and its length x2 after positioning is 600mm. The fixed steel plate 4 of the tundish beam is fixed on the tundish beam 5 by welding. The support rod 15 is fixedly connected with the fixed steel plate 4 of...

Embodiment 2

[0034] In this embodiment, the power cabinet can provide a current of 100 Hz and 500 A, which can cause the magnetic field to rotate counterclockwise. The winding in the electromagnetic swirl device body 1 adopts toroidal (Clemme) winding. The height h of the electromagnetic swirl device body 1 is 300mm, the inner diameter r is 100mm, the outer diameter R is 300mm, and the opening and closing angle α is 90°. The distance x1 from the center of the electromagnetic swirl device body 1 to the lowermost end of the ear plate 14 is 600 mm. The opening and closing control mechanism 2 adopts a mechanical method, and the length x3 of the control end of the opening and closing control mechanism 2 is 300 mm. The support rod 15 is a telescopic structure, which is driven by mechanical means, and its length x2 after positioning is 1200mm. The fixed steel plate 4 of the tundish beam is fixed on the tundish beam 5 by means of bolt connection. The support rod 15 is fixedly connected with the ...

Embodiment 3

[0036] In this embodiment, the power cabinet can provide 800Hz, 200A current, which can make the magnetic field rotate clockwise. The winding in the body 1 of the electromagnetic swirl device adopts a cogged type centralized winding. The height h of the electromagnetic swirling device body 1 is 500 mm, the inner diameter r is 150 mm, the outer diameter R is 500 mm, and the opening and closing angle α is 180°. The distance x1 from the center of the electromagnetic swirl device body 1 to the lowermost end of the ear plate 14 is 1000 mm. The opening and closing control mechanism 2 adopts a pneumatic method, and the length x3 of the control end of the opening and closing control mechanism 2 is 500mm. The support rod 15 is of fixed length, and its length x2 is 2000mm. The fixed steel plate 4 of the tundish beam is fixed on the tundish beam 5 by welding. The support rod 15 is fixedly connected with the fixed steel plate 4 of the tundish beam by means of bolt connection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com