Rectification-type supersonic cyclone separator

A cyclone separator, supersonic technology, applied in cyclone devices, devices whose axial direction of cyclone remains unchanged, etc., can solve the problems of unstable transportation, no consideration of natural gas pipeline transportation problems, losses, etc., and achieve volume Small, swirl effect elimination, high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

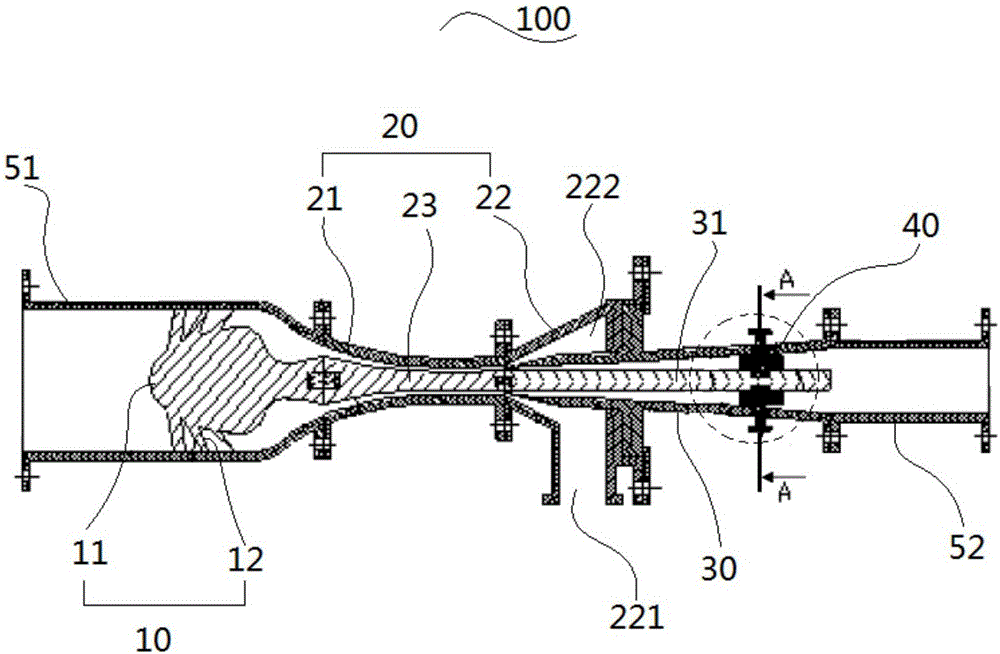

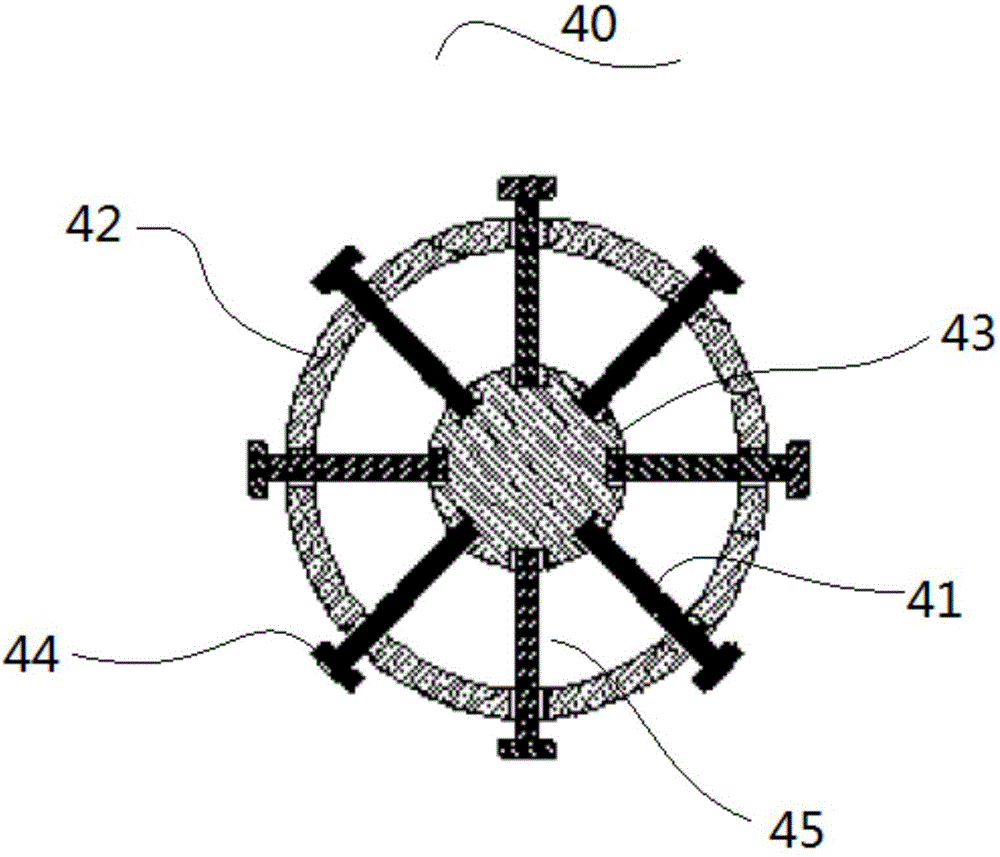

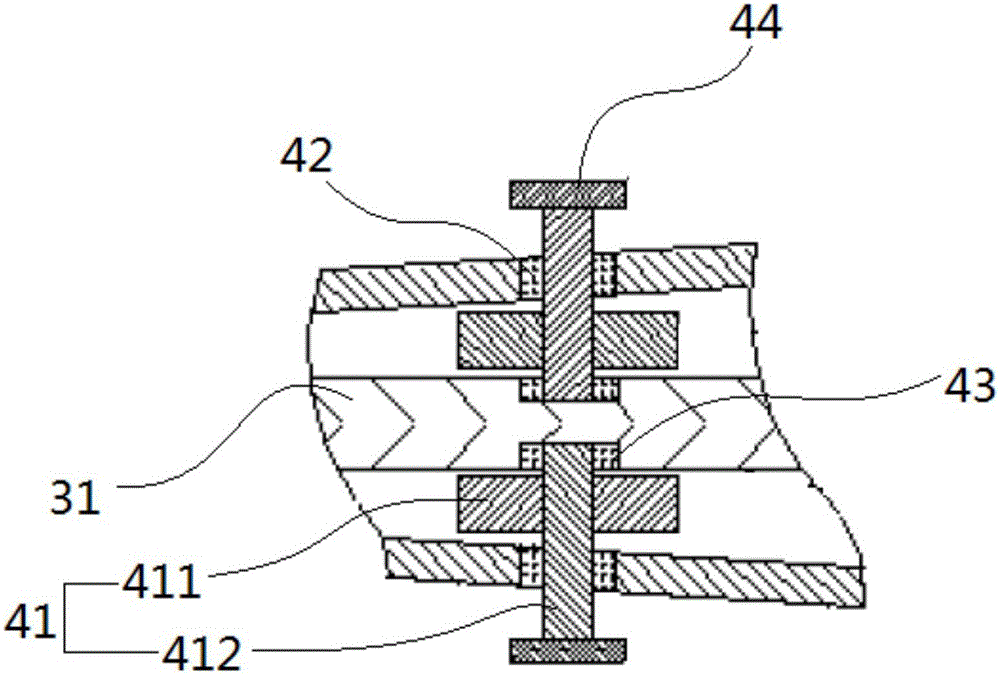

[0039] see figure 1 , which shows a rectified supersonic cyclone separator 100 according to an embodiment of the present invention. The rectifying supersonic cyclone separator 100 includes a cyclone 10 , a separator 20 and a diffuser 30 connected in sequence, and a rectifier 40 is arranged in the cavity of the diffuser 30 . When in use, the wet natural gas passes through the cyclone 10 and then enters the separator 20 for gas-liquid separation to form a cyclone-dried natural gas. The cyclone-dried natural gas is rectified by the rectifier 40 and then flows out of the rectification-type supersonic cyclone separator 100 .

[0040] In an example of the present invention, an inlet rectifying pipe 51 is connected to one end of the separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com