Low-temperature removing method of CO2 in natural gas and natural gas liquefying device adopting method

A technology for low-temperature removal and liquefaction device, applied in the field of low-temperature removal of CO2 in natural gas and natural gas liquefaction device, can solve problems such as corrosion, and achieve the effects of improving economy, less side reactions, and simple and efficient process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

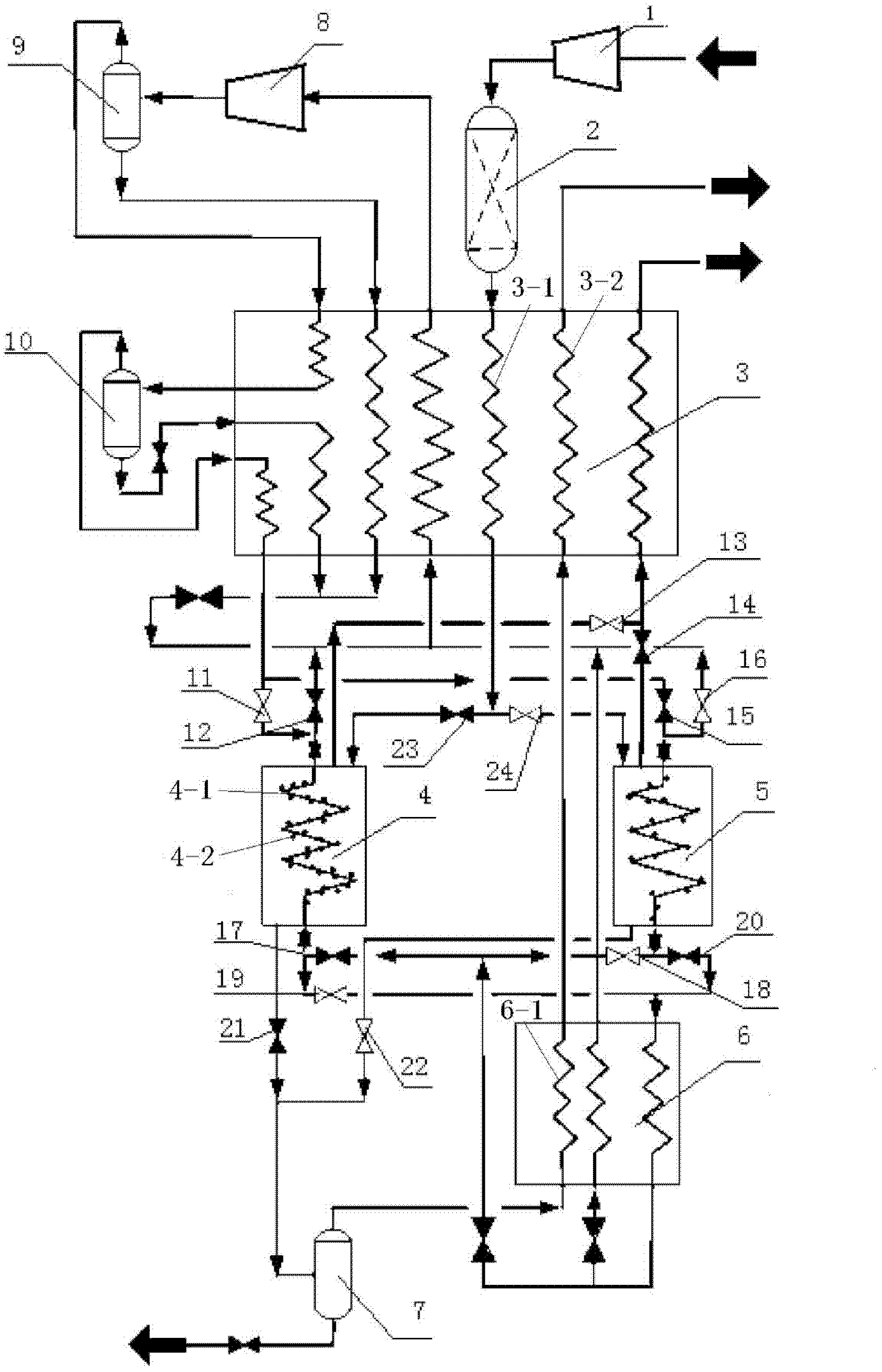

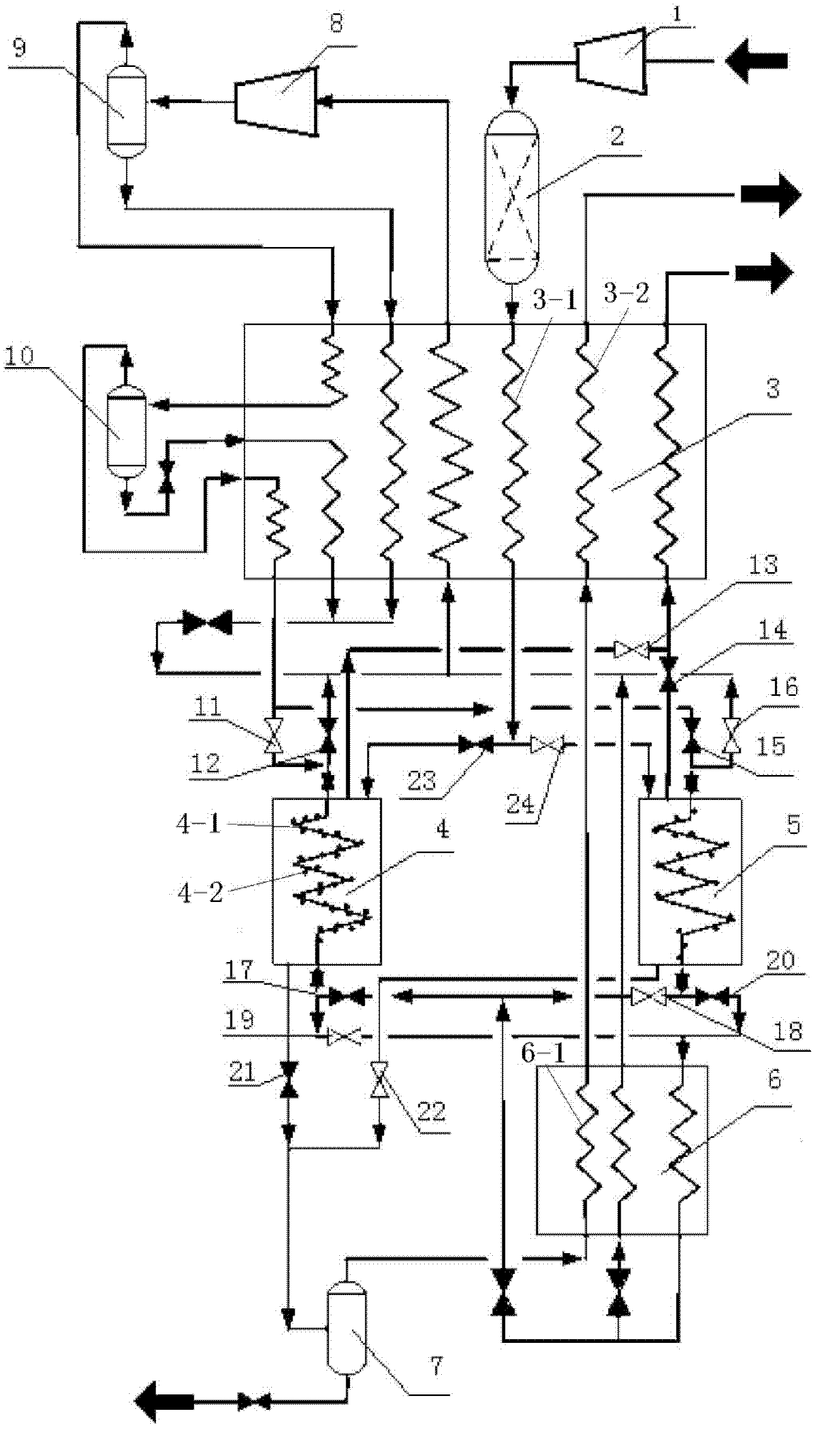

[0022] Specific Embodiment 1: The present embodiment will be specifically described below with reference to FIG. 1 . CO in natural gas 2 The low-temperature removal method includes the following steps: 1. Compressing natural gas with a natural gas compressor 1; 2. Dehydrating and drying the natural gas with a natural gas dehydration drying tower 2; 3. Precooling the natural gas with a pre-cooling heat exchanger 3; Four, use the refrigeration heat exchanger 4 to freeze the natural gas, so that the CO in the natural gas 2 Frozen into a solid state and adhered to and fixed in the freezing chamber; 5. The natural gas is discharged from the freezing chamber, thereby obtaining the removal of CO 2 of natural gas.

specific Embodiment approach 2

[0023] Specific Embodiment 2: The present embodiment will be specifically described below with reference to FIG. 1 . The difference between this embodiment and Embodiment 1 is that it also includes step 6, raising the temperature in the freezing cavity of the freezing heat exchanger 4, so as to freeze into solid CO 2 Converted to gas discharge. able to obtain CO 2 gas.

specific Embodiment approach 3

[0024] Specific Embodiment Three: The present embodiment will be specifically described below with reference to FIG. 1 . This embodiment applies CO in natural gas 2 The natural gas liquefaction device of the low-temperature removal method, which includes a refrigeration cycle system, and it also includes a natural gas compressor 1, a natural gas dehydration drying tower 2, a pre-cooling heat exchanger 3 and a freezing heat exchanger 4, and the refrigeration cycle system is a pre-cooling heat exchange Device 3 and refrigerating heat exchanger 4 provide the cooling capacity of refrigeration, the inlet of natural gas compressor 1 is used as the inlet of natural gas, the outlet of natural gas compressor 1 is connected with the natural gas inlet of dehydration drying tower 2, and the natural gas outlet of dehydration drying tower 2 is connected with pre-heater One end of the heat exchange coil 3-1 in the cold heat exchanger 3, the other end of the heat exchange coil 3-1 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com