Device for treating wastewater during production of pentaerythritol

A technology for the production of waste water and treatment devices, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of difficulty in normal survival and decomposition of pollutants, and difficulty in stably meeting discharge standards for effluent , without considering the formaldehyde removal process and other issues, to achieve the effects of easy automatic control, improved biochemical performance, and easy operation management and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

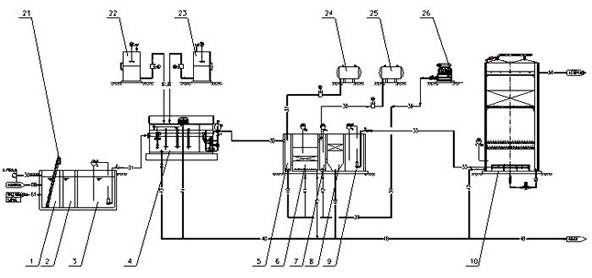

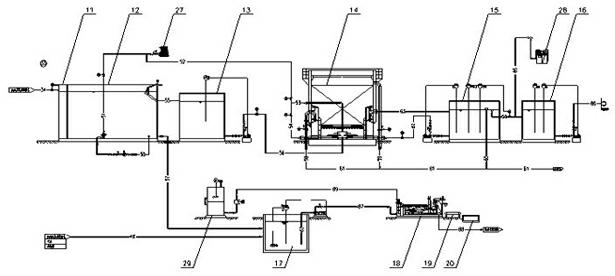

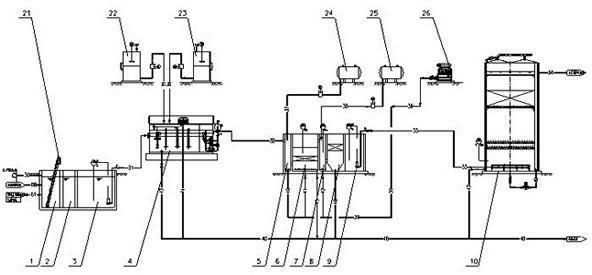

[0013] like figure 1 , figure 2 As shown, a pentaerythritol production wastewater treatment device consists of a grid tank, a mechanical grid, a grease trap, a regulating tank, a combined air flotation system, an aerated micro-electrolysis system, a high-efficiency anaerobic reactor, an improved SBR reaction tank, and a sump , biological aerated filter, monitoring tank, reuse pool and supporting acid dosing system, alkali dosing system, PAC dosing system, PAM dosing system, sludge tank, sludge filter press system and blower, and Supplemented by on-line monitoring instruments such as PH, COD, liquid level gauge and thermometer, each system is connected in an orderly manner through pipelines, and the production

[0014] The waste water inlet pipe 30 is connected to the grid tank 1, and the grid tank 1, the grease trap 2, and the adjustment tank 3 are built together on the same wall. The mechanical grid 21 is installed in the grid tank 1, and the adjustment tank 3 is discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com