Paint wastewater treatment system

A wastewater treatment system and paint technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problem of high operating cost, secondary pollution and low reliability and other problems to achieve the effect of improving flocculation effect, reducing downtime and preventing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

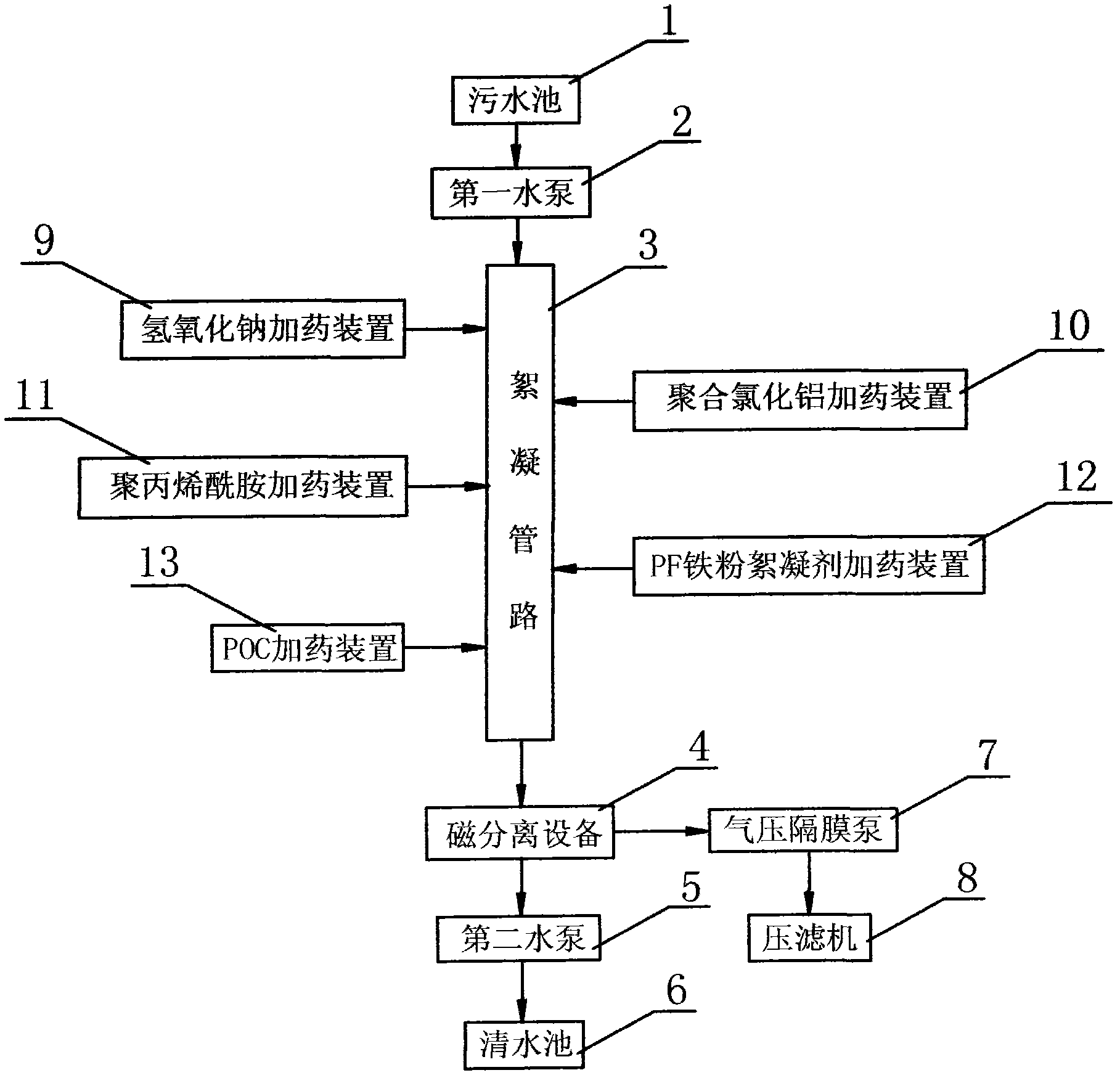

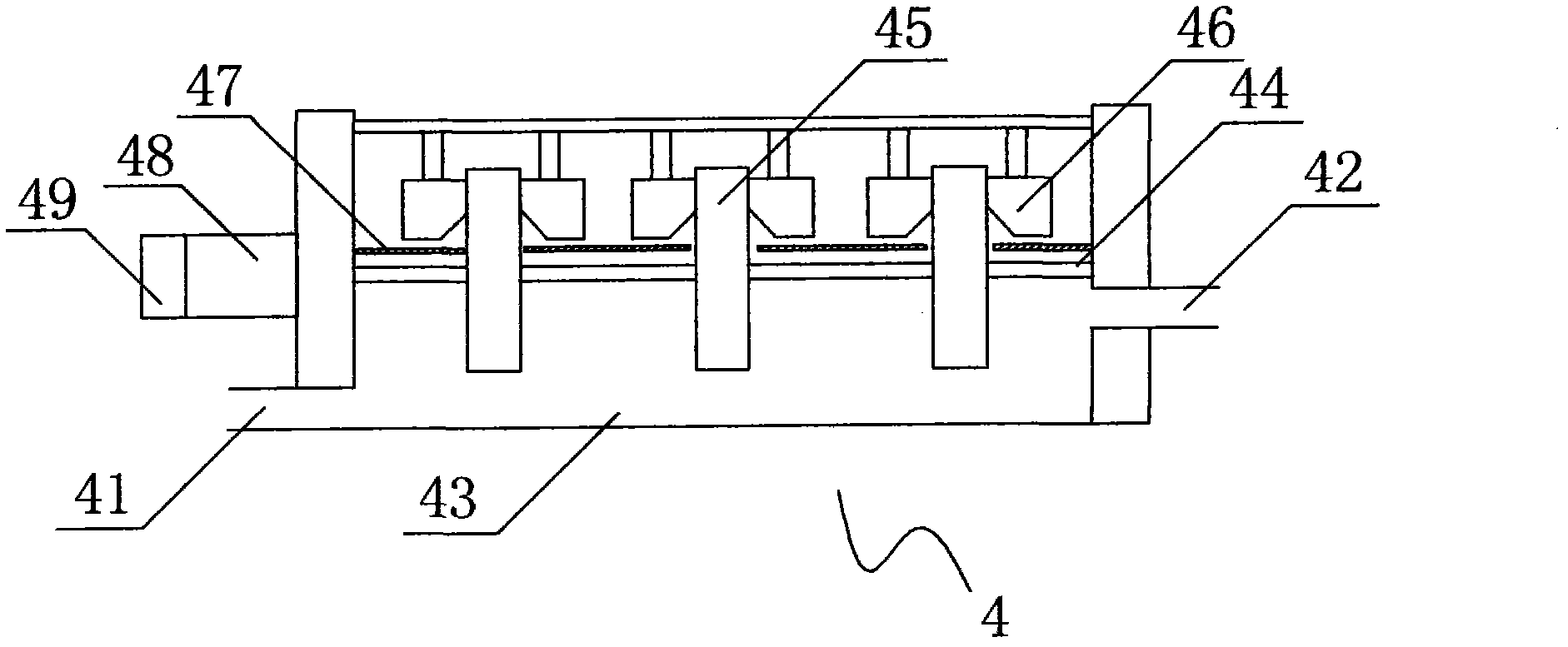

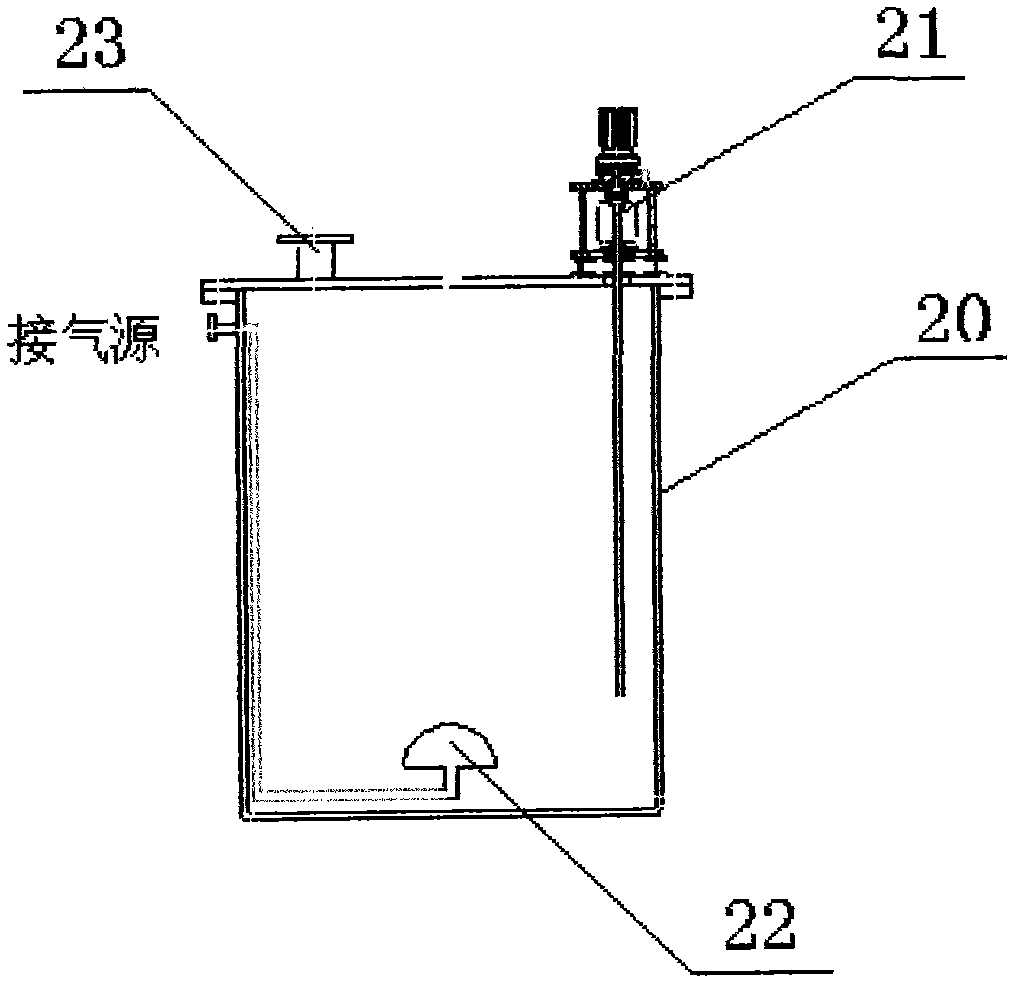

[0016] Such as figure 1 As shown, the paint wastewater treatment system of the present embodiment includes a sewage tank 1, a first water pump 2, a flocculation pipeline 3, a magnetic separation device 4, a second water pump 5, a clean water tank 6 and a dosing device, wherein the magnetic separation device 4 The water inlet pipe communicates with the sewage tank 1 through the flocculation pipeline 3 and the first water pump 2, the outlet pipe of the magnetic separation device 4 communicates with the clean water tank 6 through the second water pump 5, and the slag cleaning area of the magnetic separation device 4 communicates with the sewage tank 1 through the pneumatic diaphragm pump 7. The filter press 8 is connected. The dosing device is communicated with the flocculation pipeline 3, and the dosing device is sequentially provided with a sodium hydroxide dosing device 9, a polyaluminum chloride dosing device 10, a polyacrylamide dosing device along the waste water flow dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com