Method for flue gas desulfurization by using dyeing wastewater, and absorption tower

A printing and dyeing wastewater and absorption tower technology, which is applied in the direction of separation methods, chemical instruments and methods, textile industry wastewater treatment, etc., can solve the problems of high desulfurization operation costs, affecting implementation and application, and unfavorable environmental protection, so as to reduce pollution control costs, Save resources and promote the effect of governance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

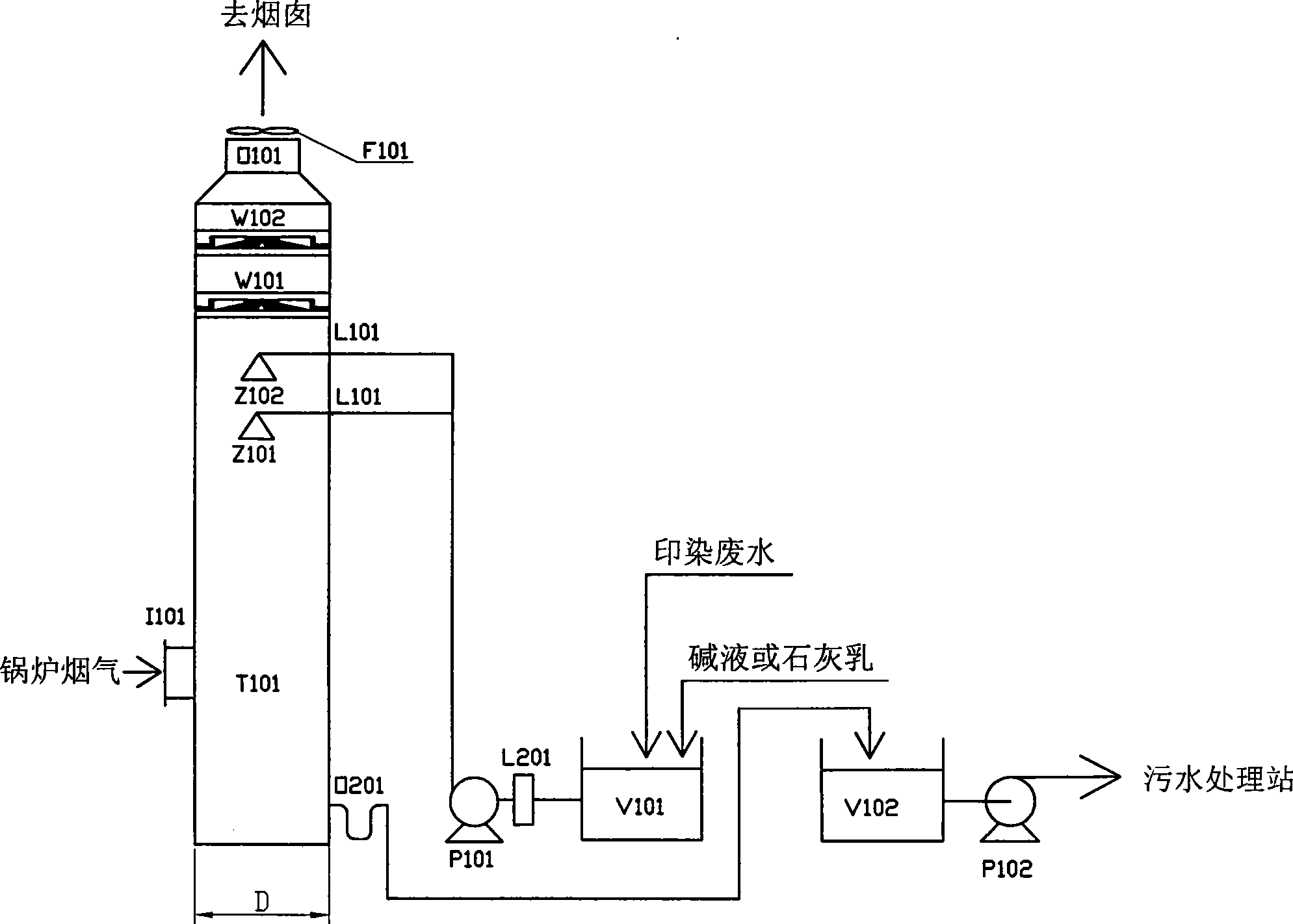

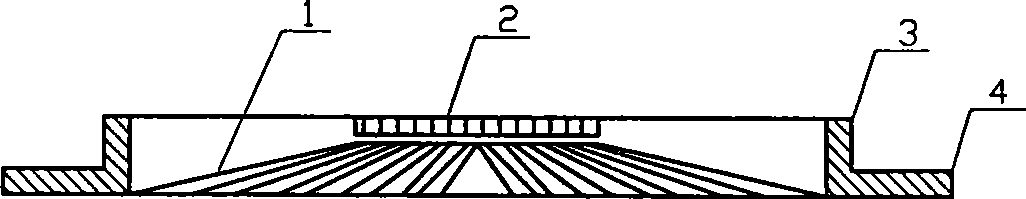

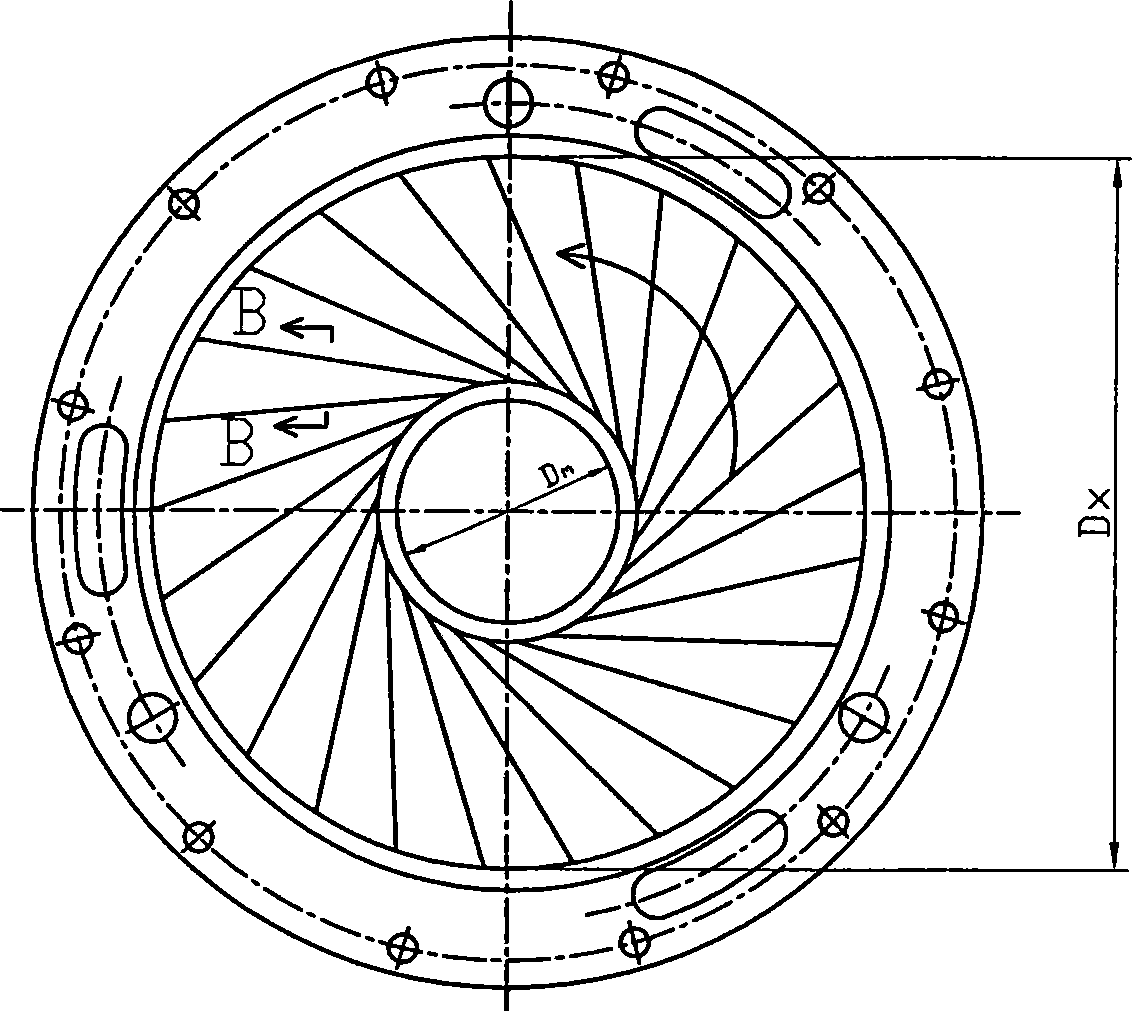

[0032] The tower diameter D=3.6~3.8m of the absorption tower T101 of the present embodiment, tower body is made of marble, its diameter Dx=3.4m of ring plate 4 of swirl plate mist eliminator, gets blind plate diameter Dm=0.33Dx= 1.1m, using 84 blades 1, blade elevation angle α=25°.

[0033] The printing and dyeing wastewater is sent to the waste lye pool V101 by the waste lye pump P101 from the collection place, and the pH of the waste lye pool is measured to be 10, and sodium alkali (containing 30% NaHO) is added to make the pH value of the waste lye in the pool Adjusted to 12.5, the alkali concentration is 0.0316mol / L, the waste lye is filtered through the filter L201, and the short fibers of the printing and dyeing wastewater are filtered out, and pumped to the spray pipes L101 and L102 located on the upper side of the absorption tower T101. The shower pipes L101 and L102 spray downward through 12 nozzles connected to them, spraying and dispersing the waste caustic soda int...

Embodiment 2

[0036] The tower diameter D=2.5~2.6m of the absorption tower T101 of the present embodiment, the tower body is made of marble, its diameter Dx=2.4m of the ring plate 4 of the swirl plate mist eliminator, get the blind plate diameter Dm=0.33Dx=0.79 m, 42 blades 1 are used, and the blade elevation angle α=25°.

[0037] The printing and dyeing wastewater is sent from the collection place to the waste lye pool V101 with the waste lye pump P101, and the pH of the waste lye pool is measured to be 11. Add lime milk to adjust the pH value of the waste lye in the pool to 13.5. The concentration is 0.3656mol / L. The waste lye is filtered through the filter L201 to filter out the short fibers of the printing and dyeing wastewater, and is pumped to the spray pipes L101 and L102 located on the upper side of the absorption tower T101. The waste water is passed through the spray pipes L101 and L102 It is sprayed downwards through the 7 nozzles connected to it, and the waste lye is sprayed and...

Embodiment 3

[0040] The tower diameter D=1.5m of the absorption tower T101 of the present embodiment, the tower body is made of granite, its diameter Dx=1.4m of the annular plate 4 of swirl plate mist eliminator, gets blind plate diameter Dm=0.33Dx=0.46m, 24 blades 1 are used, and the blade elevation angle α=25°.

[0041] The printing and dyeing wastewater is sent from the collection place to the waste lye pool V101 with the waste lye pump P101, and the pH of the waste lye pool is measured to be 12. Add lime milk to adjust the pH value of the waste lye in the pool to 12. The concentration is 0.0100mol / L. The waste lye is filtered through the filter L201 to filter out the short fibers of the printing and dyeing wastewater. It is pumped to the spray pipes L101 and L102 located on the upper side of the absorption tower T101. The waste water is passed through the spray pipes L101 and L102. Spray downwards through the 5 nozzles connected to it, and spray and disperse the waste lye into droplets...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com