Composite paper making pulp substrate and manufacturing method thereof

A substrate and pulping technology, which is applied in the field of pulping and pulp-based pulping, can solve problems such as product properties, textures, and differences in use, and achieve lower chemical oxygen consumption, good filtration, and good finish. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

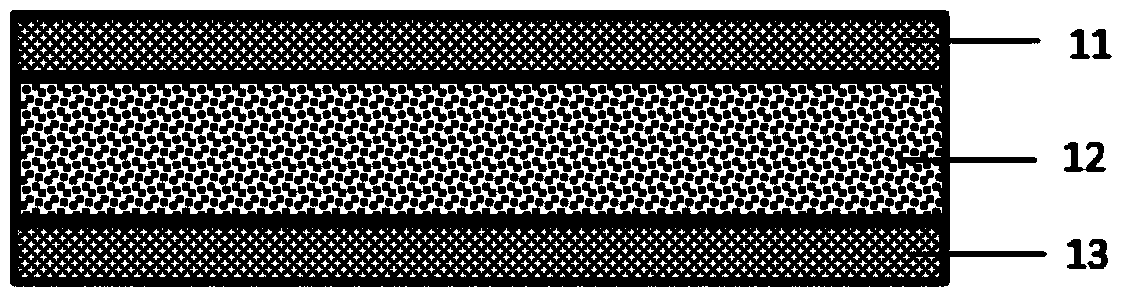

[0078] As shown in the above process steps, the bamboo fiber slurry, sugarcane slurry, and coal cinder are subjected to pulping, slurry mixing, high-concentration sand removal, low-concentration sand removal, sieving, and pulping to obtain the core surface layer slurry. The bamboo fiber pulp and the sugarcane pulp are pulped, blended, high-concentration desanding, low-concentration desanding, sieving, and pulping to obtain surface layer and bottom layer pulp.

[0079] The surface layer, the core layer slurry, and the bottom bamboo fiber slurry are compositely made by a three-layer laminated wire making machine.

[0080] The slurry of the core layer is 20-60wt%, the bamboo fiber slurry of the surface layer is 30-60wt%, and the bamboo fiber slurry of the bottom layer is 10-20wt%. The change in thickness of each layer is mainly controlled by increasing or decreasing the flow rate of the pulp. Normally, the core layer and the surface layer are stable, and the pulp in the bottom la...

Embodiment 2

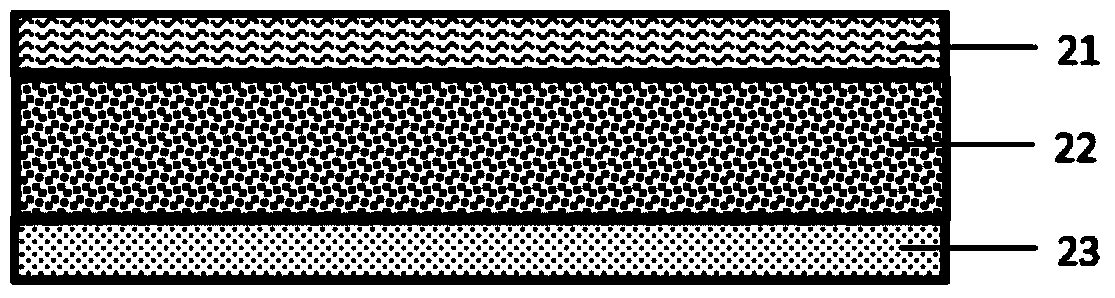

[0083] Experiments have shown that the liquid that needs to be filtered is different in its physical form, such as suspended solids concentration, particulate matter concentration, chromaticity, etc., and its chemical form, such as chemical oxygen demand (COD), is different, and the object of removal is different, such as removing liquid Organic and inorganic impurities in the In this regard, in addition to adjusting the content of the above-mentioned bamboo fiber slurry, sugarcane slurry, and cinder, according to the direction of the filtered liquid, the structure of the core layer, surface layer, and bottom layer can also be adjusted to form a coarse to fine filter layer. It is conducive to the graded filtration of impurities in the liquid from large particles, small particles, and fine particles, and keeps the liquid flowing smoothly and filtered step by step. Surface layer density 0.4±0.05g / cm 3 , the core density is about 0.35±0.05g / cm 3 , the density of the bottom laye...

Embodiment 3

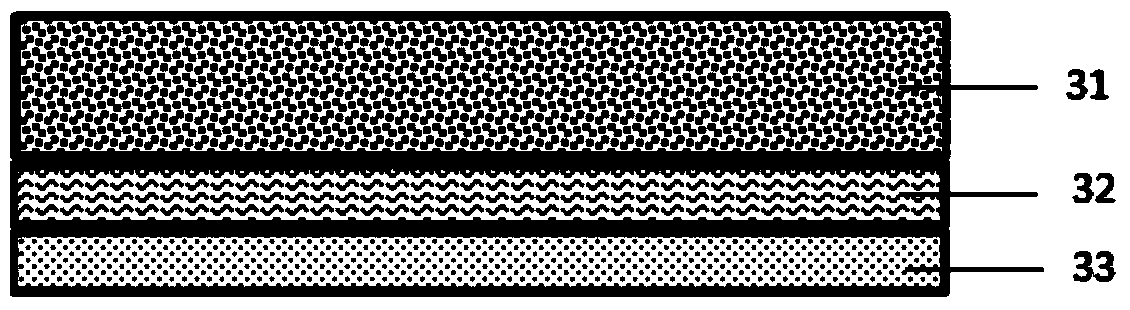

[0085] For some liquids with low concentration of suspended matter, particle concentration and turbidity, relatively high requirements for chromaticity and brightness, such as beer filtration in food processing, etc., the core layer can also be put at the lowest value of cinder ratio or even Without cinder, the bamboo fiber slurry and sugarcane slurry are mixed as the core layer, and the bamboo fiber slurry is used as the surface layer and the bottom layer, or the bamboo fiber slurry and sugarcane slurry are mixed as the core layer, and the sugarcane slurry is used as the surface layer , the bamboo fiber pulp is the bottom pulp substrate structure. ( Figure 4 with Figure 5 )

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com