Chemical tin plating liquid and preparation method thereof

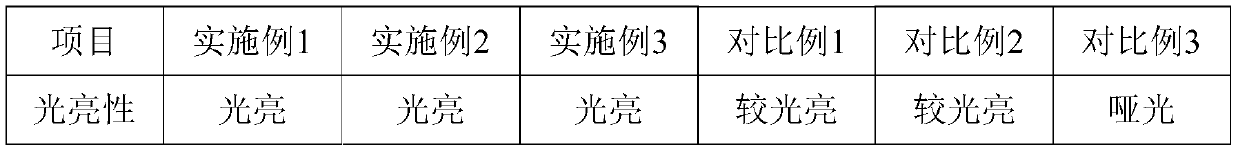

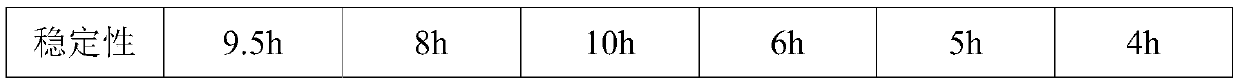

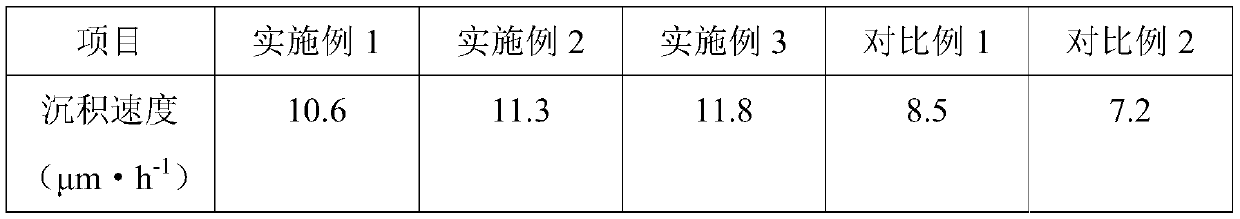

A technology of electroless tin plating and tin salt, which is applied in the direction of liquid chemical plating, metal material coating process, coating, etc. It can solve the problems of slow deposition speed, coating cannot meet the quality requirements, poor stability of plating solution, etc., and achieve improvement Stability, superior environmental protection performance, bright and beautiful coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1, a kind of electroless tin plating solution

[0035] In the electroless tin plating solution, the density is 1.84g / cm 3 The content of sulfuric acid is 33mL·L -1 , the content of tin salt is 10g·L -1 , the content of complexing agent is 85g·L -1 , the content of the multifunctional additive is 0.5g·L -1 , the content of reducing agent is 25g·L -1 , the content of functional additives is 1g·L -1 The tin salt is stannous sulfate; the complexing agent is tartaric acid; the multifunctional additive is composed of polyvinylpyrrolidone, alkyl glycoside and polyethylene glycol with an average molecular weight of 400 in a mass ratio of 1:6:15 ; The reducing agent is titanium trichloride; The functional auxiliary agent is composed of sodium lignosulfonate modified product and polysilicate ferric sulfate in a mass ratio of 5:2.

[0036] The preparation method of described sodium lignosulfonate modification is:

[0037] (1) add water to sodium lignosulfonate, b...

Embodiment 2

[0042] Embodiment 2, a kind of electroless tin plating solution

[0043] In the electroless tin plating solution, the density is 1.84g / cm 3 The content of sulfuric acid is 40mL·L -1 , the content of tin salt is 15g·L -1 , the content of complexing agent is 95g·L -1 , the content of the multifunctional additive is 1.2g·L -1 , the content of reducing agent is 40g·L -1 , the content of functional additives is 2g·L -1 ; The tin salt is stannous sulfate; the complexing agent is composed of sodium gluconate, tartaric acid and malic acid in a mass ratio of 3:1:1; the multifunctional additive is composed of polyvinylpyrrolidone, alkyl glycoside and average molecular weight 400 polyethylene glycol is composed of 2:4:12 by mass ratio; the reducing agent is titanium trichloride; 7:1 composition.

[0044] The preparation method of described sodium lignosulfonate modification is:

[0045] (1) add water to sodium lignosulfonate, be mixed with the sodium lignosulfonate aqueous soluti...

Embodiment 3

[0049] Embodiment 3, a kind of electroless tin plating solution

[0050] In the electroless tin plating solution, the density is 1.84g / cm 3 The content of sulfuric acid is 38mL·L -1 , the content of tin salt is 12g·L -1 , the content of complexing agent is 88g·L -1 , the content of the multifunctional additive is 0.7g L -1 , the content of reducing agent is 32g·L -1 , the content of functional additives is 1.2g·L -1 ; The tin salt is stannous sulfate; the complexing agent is composed of sodium gluconate and sulfamic acid in a mass ratio of 5:13; The polyethylene glycol is composed of a mass ratio of 1:5:14; the reducing agent is titanium trichloride; the functional auxiliary agent is composed of a modified sodium lignosulfonate and polysilicate ferric sulfate in a mass ratio of 5: 1 composition.

[0051] The preparation method of described sodium lignosulfonate modification is:

[0052] (1) add water to sodium lignosulfonate, be mixed with the sodium lignosulfonate aqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com