Complexation method for extracting pyrrolidone or its dissolved substance in organic dilute aqueous solution

A technology of pyrrolidone and methylpyrrolidone, which is applied in the direction of extraction water/sewage treatment, organic chemistry, etc., can solve the problems of poor extraction effect and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

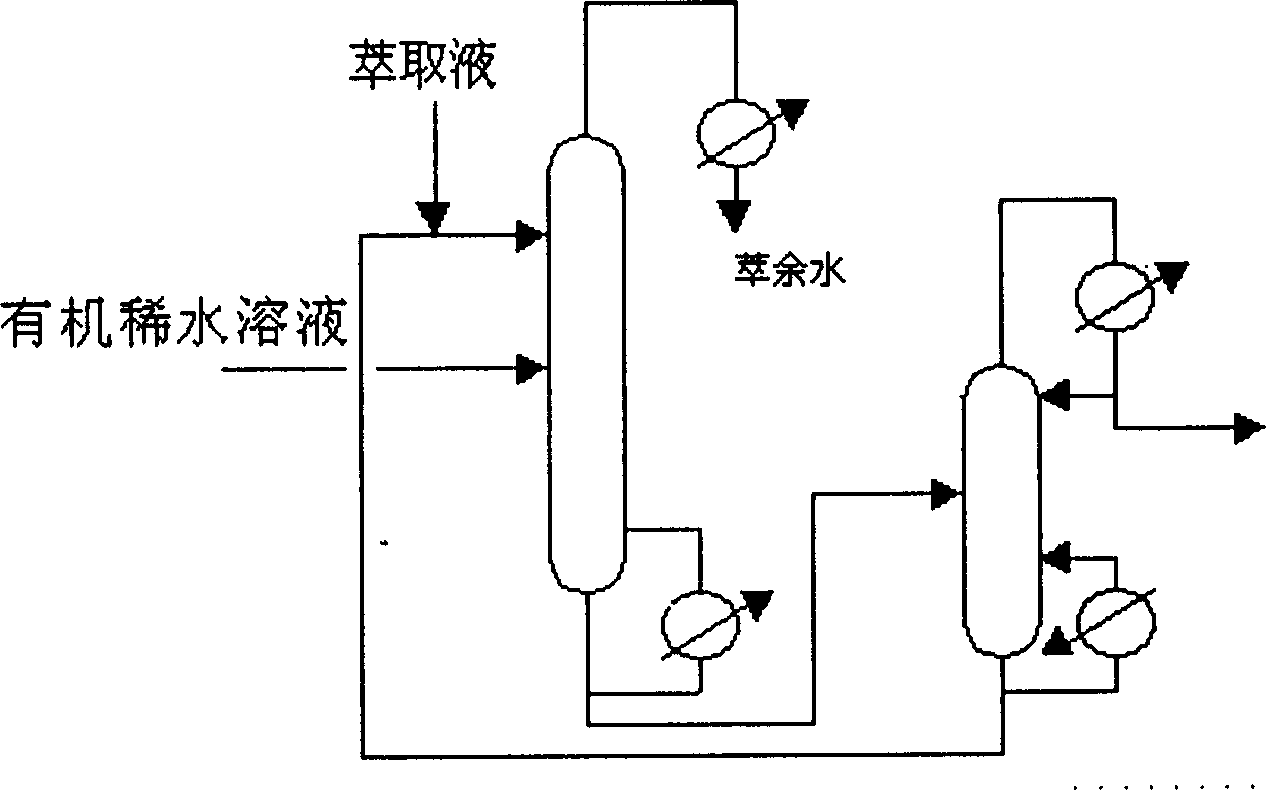

[0025] use figure 1 The flow process of a certain electronic industrial factory handles the organic dilute aqueous solution. The composition of the organic dilute aqueous solution is shown in Table 1. The extract is a mixture of 65Wt% heptanoic acid, 8Wt% oleic acid and 27Wt% kerosene. The weight ratio of the extract and the organic dilute aqueous solution is 5:3, extraction temperature 50°C, pH=6;

[0026] Send the dilute organic aqueous solution containing N-methylpyrrolidone or its compatible substance into the complexation reaction tower 1 from the middle, send the extract into the complexation reaction tower 1 from the top, and then send the complexation extraction product at the bottom of the tower into the Stripping tower 2, the raffinate water at the top of the tower is discharged;

[0027] (2) The complex extraction product sent into the stripping tower 2 is in the stripping tower, and pyrrolidone or its compatible substance is sent to the subsequent workshop section...

Embodiment 2

[0030] The composition of certain electronic industry factory organic dilute solution is shown in Table 2, adopts the complex extraction method of the present invention, and extract is the mixture of 50Wt% heptanoic acid, 5Wt% oleic acid and 45Wt% kerosene, and the weight ratio of extractant and dilute aqueous solution is 5:1, the extraction temperature was 60°C, pH=7.5, the others were the same as in Example 1, and the results are shown in Table 3.

[0031] Composition (weight)%

[0032] Example 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com