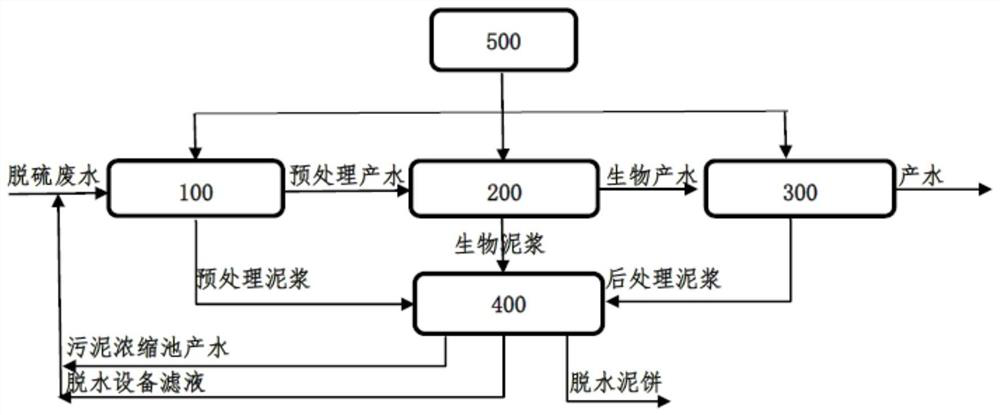

Biological treatment system for removing pollutants in flue gas desulfurization wastewater

A technology for biological treatment and desulfurization of wastewater, applied in gaseous effluent wastewater treatment, dehydration/drying/concentrated sludge treatment, water/sewage treatment, etc. The effect of reducing the amount of nitrogen and ammonia nitrogen, reducing equipment investment and operating costs, and resisting system shocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

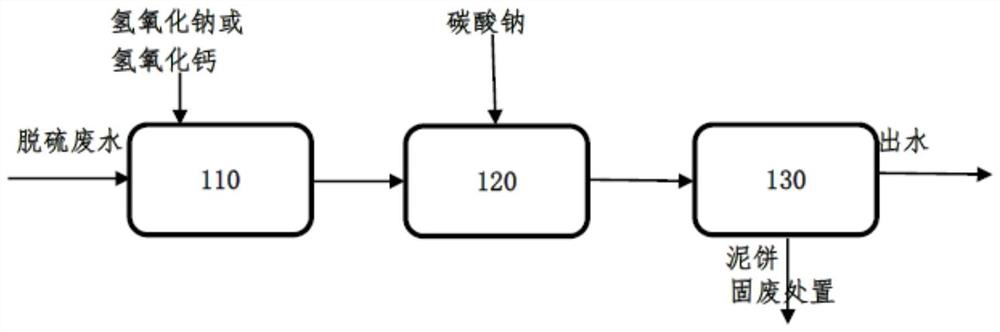

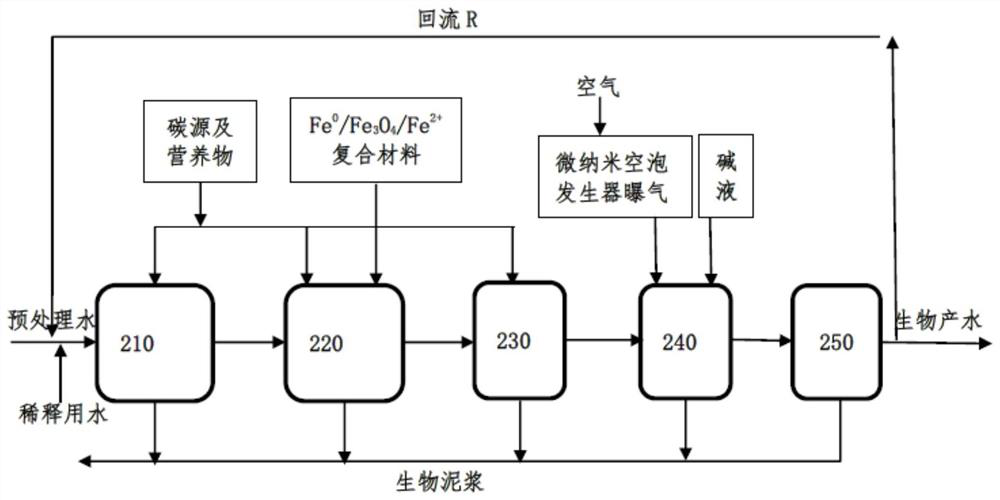

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0106] The preparation method of the porous microbial carrier comprises the following steps:

[0107] S110, weighing: weigh each component according to the formula mass ratio, and set aside;

[0108] S120, put polyether 330, adsorbent, triethylenediamine, water, and additives into the reactor, stir for 10-20min, and mix well; then add MZL type polymer absorbent into the reactor, And add 2,4-toluene diisocyanate and 2,6-toluene diisocyanate under stirring, and stir for 2-5 minutes;

[0109] S130. Evenly coat the inner surface of the foaming mold with a release agent, evenly coat the prefabricated mixture in the mold, close the mold, place it at 40° C. for 24 hours or at room temperature for more than 36 hours, and perform foaming. A porous microbial carrier shaped body;

[0110] S140, put the porous microbial carrier molded body into the reactor, soak and react in 10% sodium carbonate solution for 6-12 hours, then wash to neutral; then soak in 2% acetic acid solution for 6-12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com