Desulfurization liquid for absorbing H2S, desulfurization system and desulfurization method

A desulfurization system and desulfurization liquid technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as poor desulfurization effect, and achieve the effects of easy sedimentation and separation and large sulfur particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Preparation of iron-based ionic liquid-polyethylene glycol dimethyl ether compound desulfurization solution

[0057] (1) Preparation of iron-based ionic liquid

[0058] Add 759kg of chlorobutane to the autoclave, pump out 641kg of N-methylimidazole, heat to 70°C with steam or water bath, and turn on the mixer for constant temperature reaction for 72h.

[0059] After 72 hours, turn off the heating device, and slowly add ferric chloride to the high-pressure reactor. Since ferric chloride dissolves in the above-mentioned substances, it will generate heat. For safety reasons, ferric chloride can be divided into 20 minutes within 12 hours. For each dosing, a total of 1000kg of ferric chloride needs to be put in, and after all of it is put in, it is cooled to room temperature to obtain 1-butyl-3-methylimidazolium chloride iron-based ionic liquid.

[0060] (2) Compounding of iron-based ionic liquids and additives

[0061] Polyethylene glycol dimethyl ether: After the iron-ba...

Embodiment 2

[0065] Preparation of iron-based ionic liquid-sulfolane compound desulfurization solution:

[0066] After cooling the iron-based ionic liquid prepared in Example 1 to room temperature, continue to add 480-960 kg of sulfolane into the autoclave, and stir for 2 hours to obtain the iron-based ionic liquid-sulfolane compound desulfurization solution.

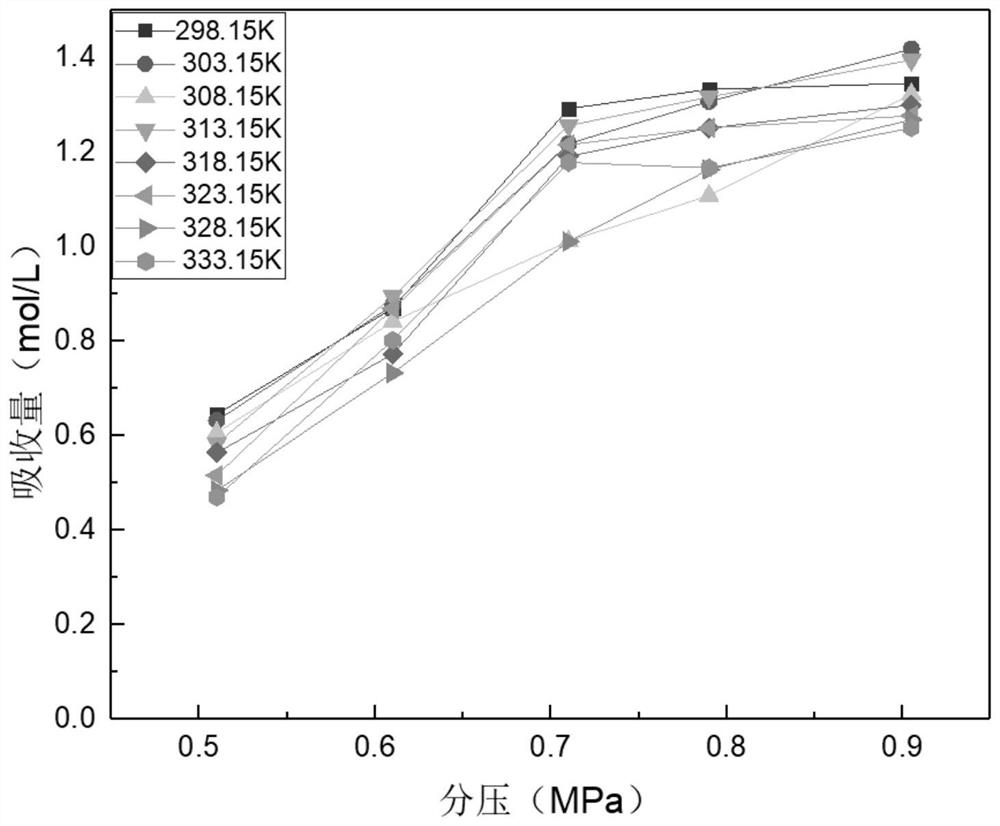

[0067] Advantages of choosing sulfolane:

[0068] (1) Low viscosity and reduced surface tension make the system less prone to foaming; (2) Compared with iron-based ionic liquid-polyethylene glycol dimethyl ether compound desulfurization liquid, it is easier to absorb hydrogen sulfide under high pressure conditions; (3) The absorption of methane is very small; (4) the sulfolane compound desulfurization liquid absorbs CO 2 Compared with the polyethylene glycol dimethyl ether system, the capacity increased by 20%.

Embodiment 3

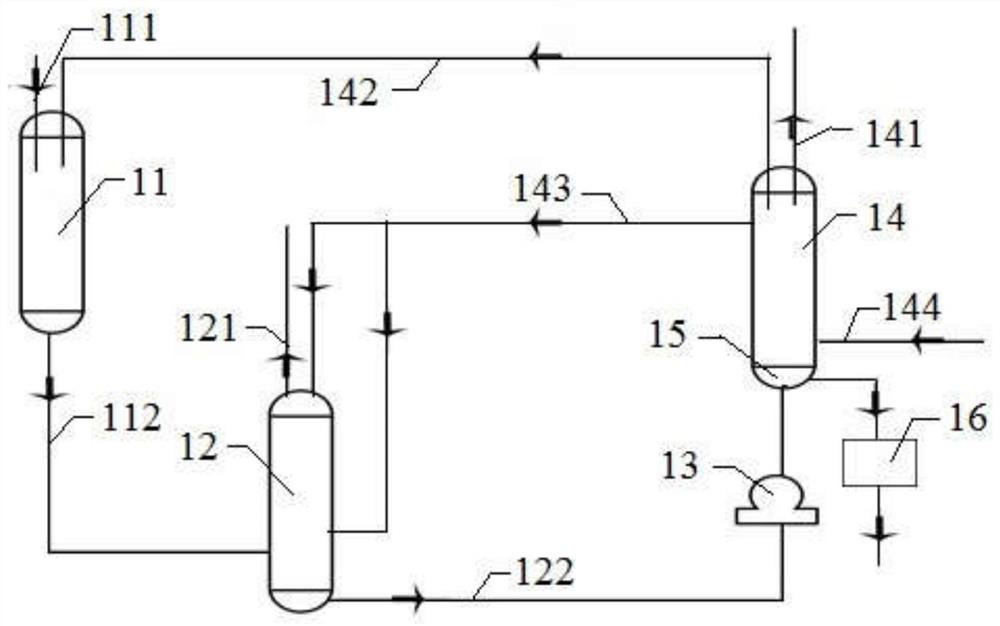

[0070] Adopt the desulfurization liquid prepared in embodiment 1 and embodiment 2 to absorb H 2 S desulfurization system, such as figure 1 As shown, the desulfurization system includes a primary desulfurization tower 11, a secondary desulfurization tower 12, a slurry pump 13, a regeneration tower 14, a sulfur separation device 15, and a sulfur melting kettle 16;

[0071] The desulfurization liquid is filled in the primary desulfurization tower 11, the feed gas inlet 111 is provided on the top of the primary desulfurization tower 11, the first pipeline 112 is installed at the lower end of the primary desulfurization tower 11, the primary desulfurization tower 11 and the secondary desulfurization tower 12 are communicated through the first pipeline 112;

[0072] Desulfurization liquid is filled in the secondary desulfurization tower 12, and the top of the secondary desulfurization tower 12 is provided with a purified gas outlet 121, and a second pipeline 122 is installed under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com