Treatment method for wastewater of oil and gas field

A treatment method and technology of oil and gas fields, applied in mining wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc. Chemical utilization rate, easy automatic control, low water content in solid phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

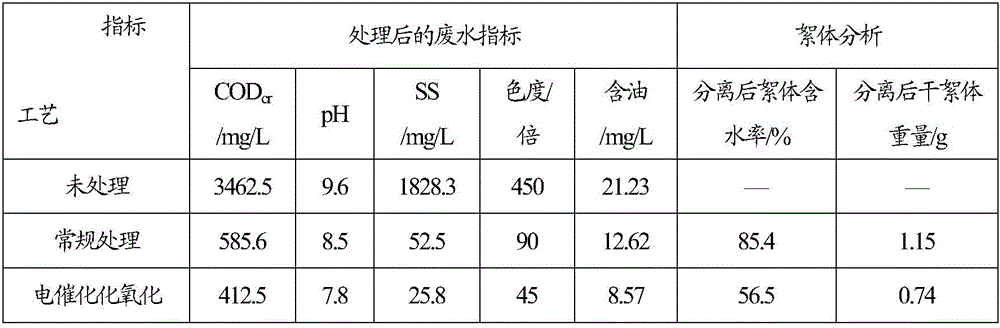

[0040] Comparison of treatment effect between electrocatalytic oxidation and conventional treatment technology

[0041] Experimental conditions for the control group: Take 500mL of drilling wastewater, add gel-breaking coagulant PAC (polyaluminum chloride) 6000mg / L, stir and coagulate for 15min, use sodium hydroxide to adjust the pH to 9-10, add PAM (polyacrylamide) 30mg / L, using a pulse power supply to stir slowly for 2-3 minutes, and then centrifuged to separate the aqueous phase COD, pH, SS, chroma, oil content, floc moisture content, floc moisture content, and dry floc weight.

[0042] Experimental conditions of the present invention: Take 500mL of drilling wastewater, control the electrocatalytic oxidation time for 30 minutes, add surface organically modified permanent magnet powder as a magnetic flocculant, the dosage is 6g / L drilling wastewater, stir flocculation and sedimentation for 10 minutes, and use a disk for solid-liquid separation , after the separation, the mag...

Embodiment 2

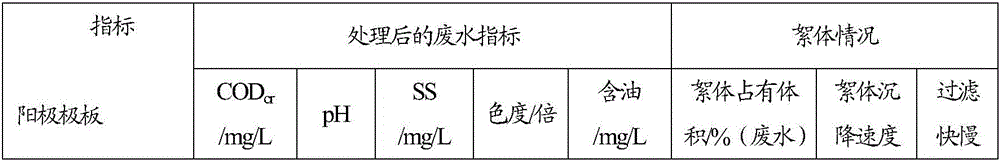

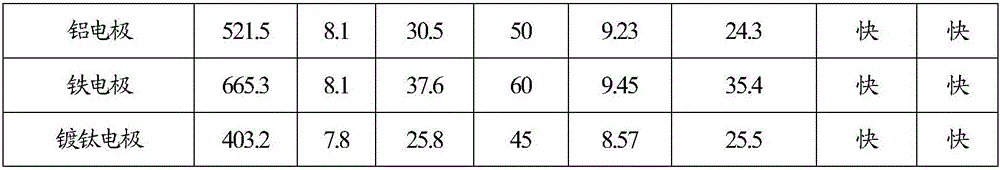

[0046] Comparative Study of Electrode Plates

[0047] Take 500mL of drilling wastewater, use aluminum electrode, iron electrode, and titanium-plated electrode as anode respectively, use graphite as cathode, use pulse power supply, control the electrocatalytic oxidation time for 30min, and use powdered titanium dioxide (particle size: 200 mesh) as the catalyst, and the amount of titanium dioxide used is 10wt% of the waste water, adding surface organically modified permanent magnet powder as a magnetic flocculant, the dosage is 6g / L drilling wastewater, stirring flocculation and sedimentation for 10min, using a disk for solid-liquid separation, and the separated solid phase is oscillated to recover the magnetic flocculant , fine filtration of the water phase after separation, test and analysis of COD after fine filtration cr, pH, SS, chroma, oil content, floc water content, floc sedimentation velocity and filtration speed, the results are shown in Table 2.

[0048] Table 2 Effe...

Embodiment 3

[0052] Effect of power supply type on processing effect

[0053] Aluminum electrodes and titanium-plated electrodes are used as anodes, and graphite is used as cathodes. DC power supply and pulse power supply are used to treat drilling wastewater respectively. The catalyst uses powdered titanium dioxide (particle size: 200 mesh), and the amount of titanium dioxide used is 10wt% of the wastewater. Keep the same conditions, add surface organically modified permanent magnet powder as a magnetic flocculant, the dosage is 6g / L drilling wastewater, stir and flocculate for 10 minutes, use a disk for solid-liquid separation, the separated solid phase oscillates to recover the magnetic flocculant, separate After fine filtration of the water phase, test and analyze COD after fine filtration cr , pH, SS, chroma, oil content, the results are shown in Table 3.

[0054] Table 3 Effects of different plates and different power types on drilling wastewater treatment

[0055]

[0056] It c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com