Ethyl polyethylene polyamine polymethacrylate chelating flocculant and preparation method thereof

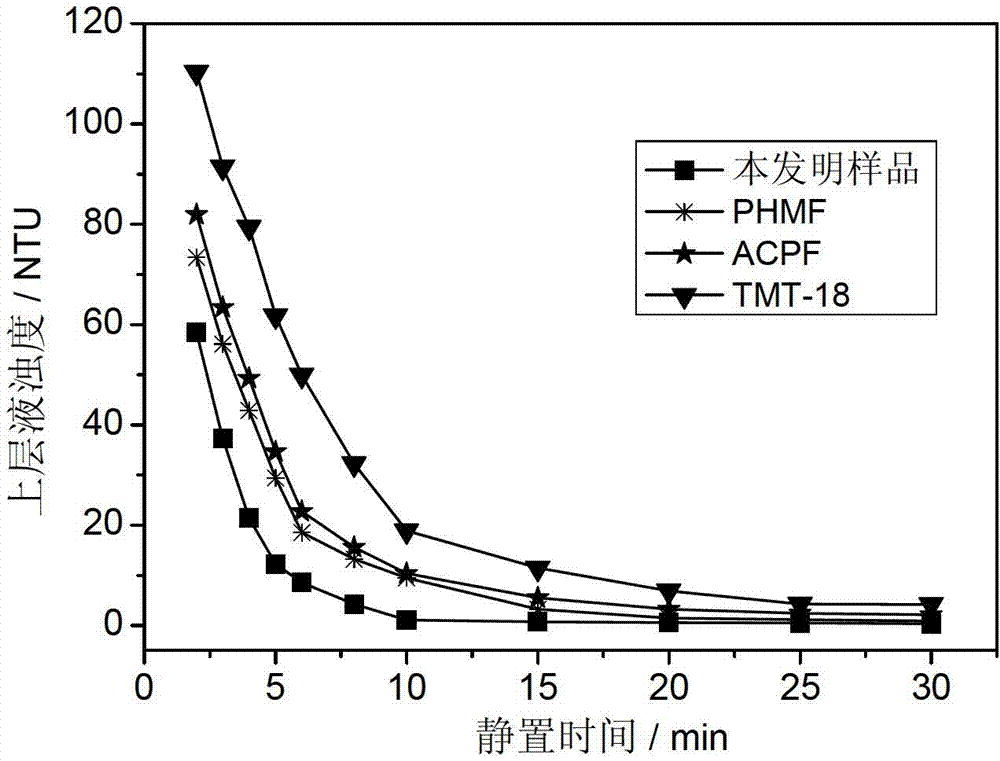

A technology of poly(ethylene polyamine ethyl ester) and poly(ethylene polyamine) polymethacrylate, applied in the direction of flocculation/precipitation water/sewage treatment, etc. Treatment effect, reduction of volume and moisture content, effect of promoting floc growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

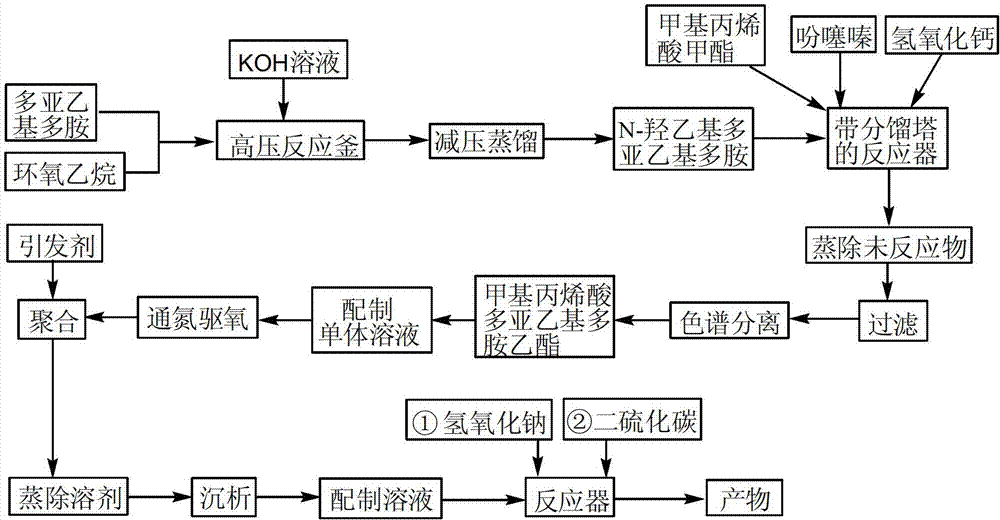

Method used

Image

Examples

Embodiment 1

[0032] (1) According to the molar ratio of ethylenediamine and ethylene oxide is 2:1, add 301g of ethylenediamine into a 1L autoclave, and then add 16.4g of potassium hydroxide with a concentration of 10% by mass Solution, heated to boiling, then passed through 110.1g of ethylene oxide, reacted at 160°C and 0.5MPa for 3h, decompressed to 1333Pa, collected fractions at 102-104.5°C, and obtained 242.5g of N-hydroxyethylethylenediamine;

[0033] (2) Add N-hydroxyethylethylenediamine and 467g of methyl methacrylate obtained in step (1) into a 1.5L reactor with a stirrer, a thermometer and a fractionation tower, and then add 25.9g of calcium hydroxide and 6.5g of phenothiazine, reacted at 70°C for 4h, decompressed to 1333Pa to distill off unreacted methyl methacrylate and N-hydroxyethylethylenediamine, then filtered to remove calcium hydroxide, separated and purified by column chromatography to obtain 347.9 g ethylenediamine ethyl methacrylate;

[0034] (3) Dissolve the ethylened...

Embodiment 2

[0039] (1) According to the molar ratio of ethylenediamine and ethylene oxide of 2.05:1, add 308.5g of ethylenediamine into a 1L high-pressure reactor, and then add 21g of potassium hydroxide with a concentration of 10% by mass Solution, heated to boiling, then passed through 110.1g of ethylene oxide, reacted at 170°C and 0.65MPa for 2.5h, decompressed to 1333Pa, collected fractions at 102-104.5°C, and obtained 243.6g of N-hydroxyethylethylenediamine ;

[0040] (2) Add N-hydroxyethylethylenediamine and 515.4g of methyl methacrylate obtained in step (1) into a 1.5L reactor equipped with a stirrer, thermometer and fractionation tower, and then add 29.5g of calcium hydroxide and 7g of phenothiazine, reacted at 80°C for 3.5h, decompressed to 1333Pa to evaporate unreacted methyl methacrylate and N-hydroxyethylethylenediamine, then filtered to remove calcium hydroxide, and purified by column chromatography to obtain 352.2g ethylenediamine ethyl methacrylate;

[0041] (3) Dissolve ...

Embodiment 3

[0045] (1) According to the molar ratio of ethylenediamine and ethylene oxide is 2.1:1, add 316g of ethylenediamine into a 1L high-pressure reactor, and then add 26g of potassium hydroxide solution with a concentration of 10% by mass , heated to boiling, then passed 110.1g of ethylene oxide, reacted at 180°C and 0.8MPa for 2h, decompressed to 1333Pa, collected fractions at 102-104.5°C, and obtained 243.2g of N-hydroxyethylethylenediamine;

[0046] (2) Add N-hydroxyethylethylenediamine and 561.1g of methyl methacrylate obtained in step (1) into a 1.5L reactor equipped with a stirrer, thermometer and fractionation tower, and then add 31.1g of calcium hydroxide and 7.45g of phenothiazine, reacted at 90°C for 3h, decompressed to 1333Pa to evaporate unreacted methyl methacrylate and N-hydroxyethylethylenediamine, then filtered to remove calcium hydroxide, and purified by column chromatography to obtain 349.5g ethylenediamine ethyl methacrylate;

[0047] (3) Dissolve ethylenediami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com