Oil solubility compound-type suspended bed hydrocracking catalyst as well as preparation method thereof

A hydrocracking and catalyst technology, which is applied in physical/chemical process catalysts, chemical instruments and methods, hydrocarbon oil cracking, etc., can solve the problems of low effective metal content, large impact on the environment and people, and high catalyst preparation costs, reaching Avoid agglomeration and particle size, low toxicity and corrosion, and maintain the effect of long-term operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

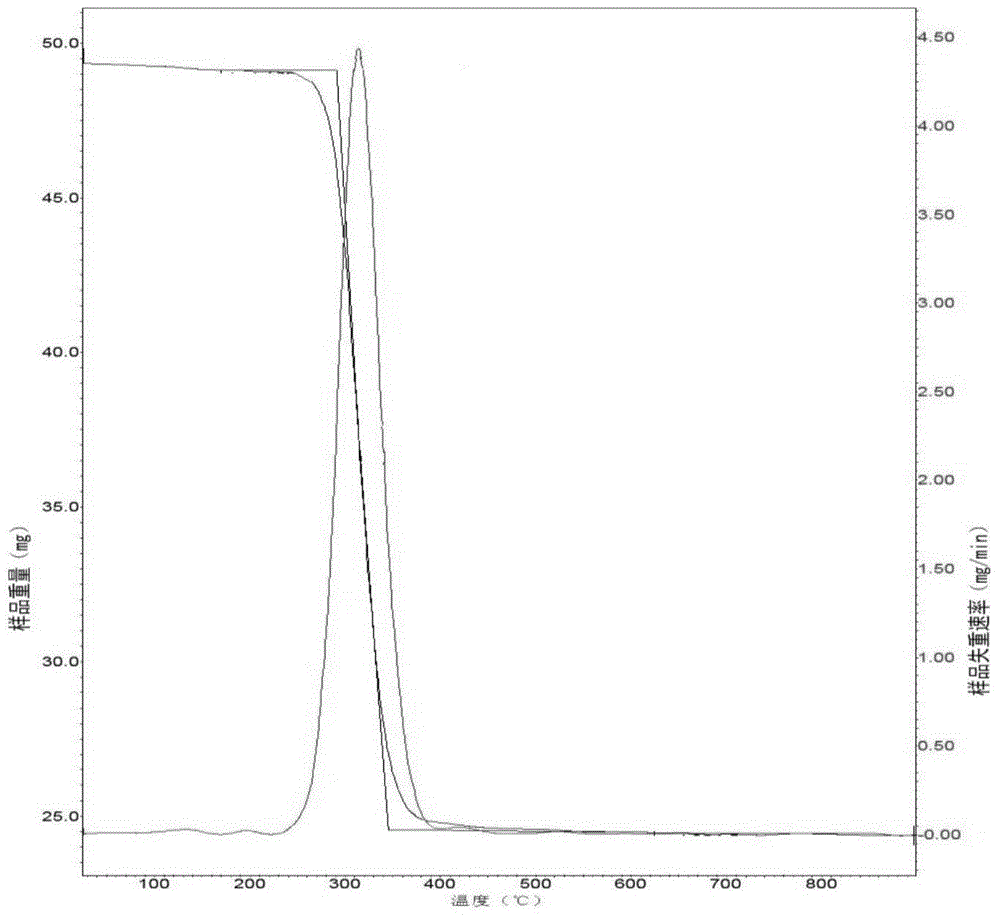

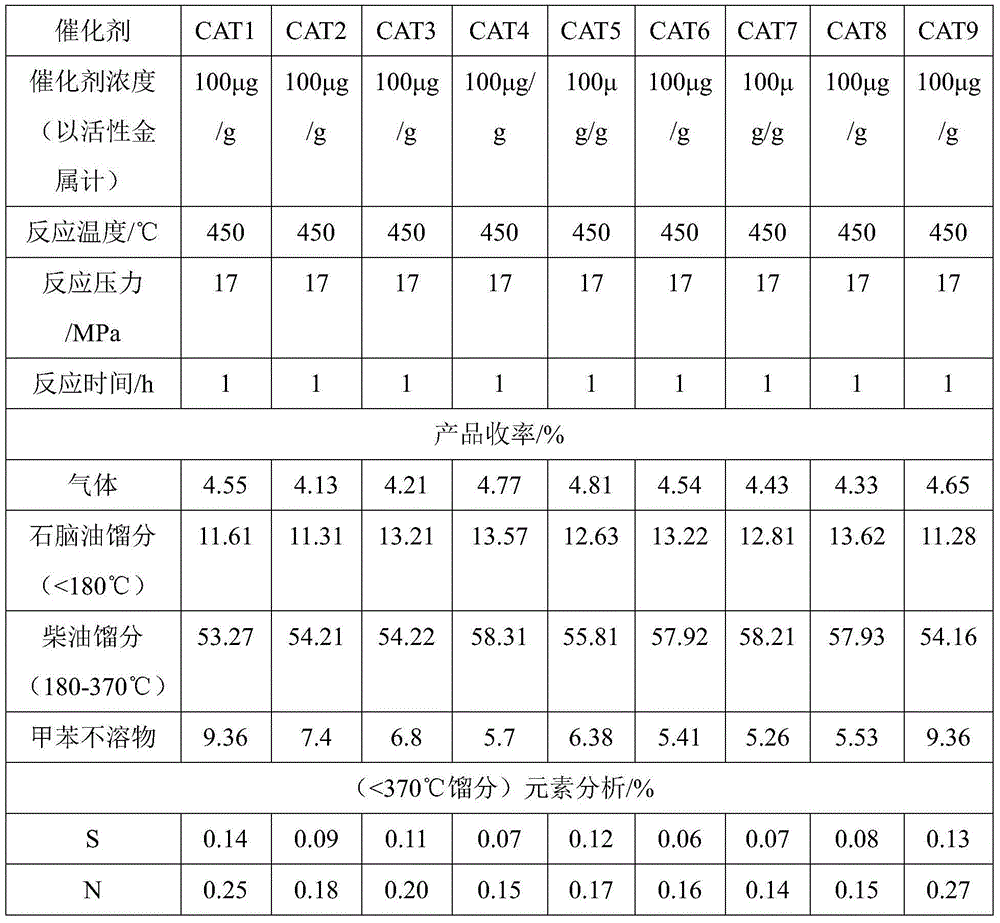

[0040] In a 250ml reaction bottle, add 0.05mol of molybdenum trioxide to an aqueous solution containing 0.23mol of sodium sulfide, stir at room temperature until completely dissolved, add 20ml of petroleum ether and dropwise add 10g of 30% sulfuric acid, and then add 0.03mol of dinormal Butylamine and 0.03mol carbon disulfide were heated to 74°C, reacted for 4 hours, filtered and washed with denatured alcohol to obtain a yellow solid catalyst product (CAT1), with a yield of 80% and a molybdenum content of about 27%. figure 1 is the TG-DTG curve of CAT1, by figure 1 It can be seen that the catalyst of the present invention remains stable and does not decompose when the temperature is lower than 200°C, and decomposes when the temperature rises to around 340°C after entering the hydrogenation reactor.

Embodiment 2

[0042] In a 500ml reaction flask, add 0.25mol of tellurium dioxide to 250ml of 1mol / L Na2S solution, heat to 45°C until the tellurium dioxide is completely dissolved, then add 0.03mol of di-n-butylamine and 0.03mol of carbon disulfide to control the reaction temperature At 60°C, add 15% hydrochloric acid dropwise under stirring to adjust the pH value between 3 and 5, react for 4 hours, filter and wash with industrial alcohol to obtain a yellow solid catalyst product (CAT2), with a yield of 80% and a tellurium content of 19%.

Embodiment 3

[0044] In a 250ml reaction bottle, add 0.05mol sodium tungstate dihydrate, 0.23mol sodium sulfide, 100ml deionized water, and add 30% sulfuric acid to adjust the pH value to 2-4. After completion, add 0.05mol of di-n-butylamine, 25ml of petroleum ether, slowly add 0.05ml of carbon disulfide at room temperature, stir for 30 minutes, heat up to 80°C, react for 6h, filter and wash with denatured alcohol, and obtain a beige solid catalyst product (coded as CAT3 ), the yield is 85%, and the tungsten content is 15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com