Harmless treatment method of arsenic-bearing slag liquid of biological preoxidation-cyanidation gold extracting process of arsenic-bearing gold concentrate

A technology of harmless treatment and pre-oxidation, applied in the direction of improving process efficiency, can solve problems such as poor stability of arsenic-containing cyanide tailings, and achieve the effects of high stability, low slag rate and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

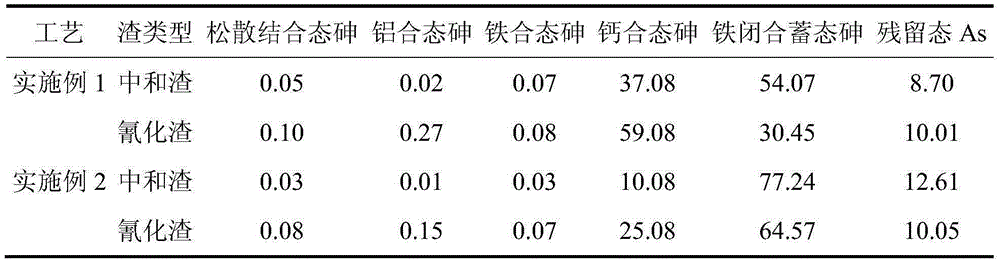

[0032] Embodiment 1 (comparative example)

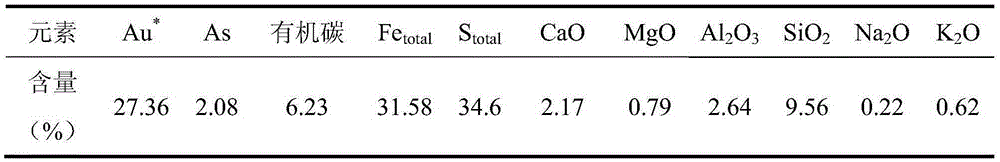

[0033] Conventional treatment process: Weigh 2kg of gold concentrate, use 9K medium as nutrients, gold concentrate -45μm particle size accounts for 75%, pulp concentration 18%, temperature 40-42°C, initial pH value of oxidation is 1.6, stirring speed is 550rpm, oxidation time of 6 days, dissolved oxygen amount of 1-2ppm, pH value of the solution after oxidation is 0.6, iron ion concentration of 17g / L, arsenic concentration of 2g / L, and finally the oxidation rate of sulfide is 90%. After oxidation, the liquid is adjusted to pH 4.0 with limestone, and then adjusted to pH 9.0 with lime. The concentration of iron ions is 0.44mg / L, and the concentration of arsenic is 0.01mg / L. The separation performance is poor, and the analysis results of the form distribution of arsenic in the slag are shown in Table 1; the carbon leaching conditions of the oxide slag are: time 24 hours, pH 10, activated carbon dosage 20g / L, sodium cyanide dosage 4kg / t ...

Embodiment 2

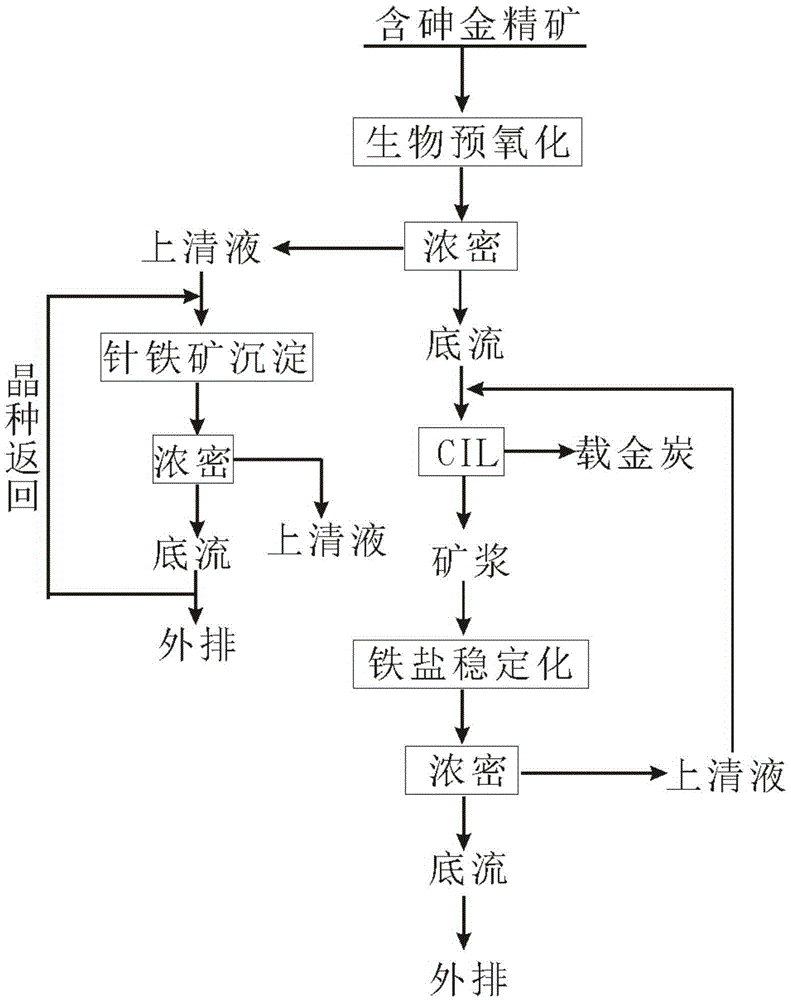

[0035] Such as figure 1 shown, including the following steps:

[0036](1) 2 kg of arsenic-containing gold concentrate is pre-oxidized with a bio-tank leaching process to obtain pre-oxidized ore pulp. The specific parameters of the bio-tank leaching are as follows: 9K medium is used as a nutrient substance, the ore-45 μm particle size accounts for 75%, and the temperature is 40-42°C, the time is 6 days, the pulp concentration is 18%, the initial pH is 1.6, the stirring speed is 550rpm, the dissolved oxygen is 1-2ppm, the pH of the obtained pre-oxidized pulp is 0.6, the iron ion concentration is 17g / L, The arsenic concentration is 2g / L, and the oxidation rate of sulfide is 90%;

[0037] (2) Carrying out solid-liquid separation to the above-mentioned preoxidized ore pulp to obtain the first supernatant and the first underflow;

[0038] (3) Pre-neutralize the first supernatant with gold concentrate to pH = 2.0-2.5 and then separate the solid and liquid to obtain the second super...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com