Ultrasonic oil-water separation device

An oil-water separation device, ultrasonic technology, applied in the direction of liquid separation, separation method, chemical/physical/physical-chemical process of applying energy, etc. Secondary pollution and other problems, to achieve considerable economic benefits, reduce mechanical strength, and increase the effect of solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

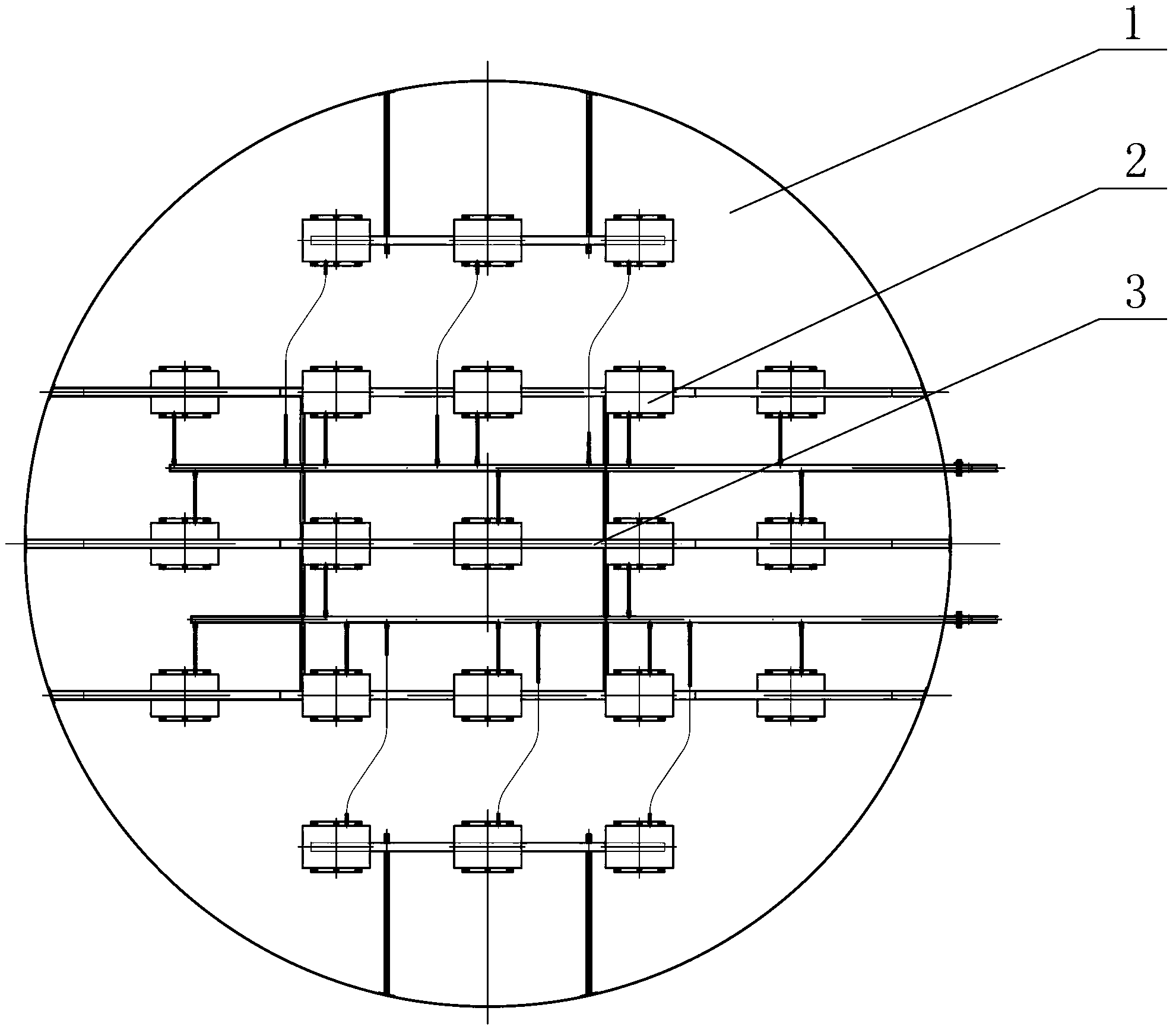

[0021] Such as figure 1 As shown, an ultrasonic oil-water separation device includes a water storage tank 1, a plurality of ultrasonic transmitting vibration boxes 2 are evenly distributed inside the water storage tank 1, and the distance between two adjacent ultrasonic transmitting vibration boxes 2 is 1800 mm ±100 mm, the optimum distance here is 1800mm. A plurality of ultrasonic transmitting vibration boxes 2 are fixed inside the water storage tank 1 with a 304 stainless steel bracket assembly 3 .

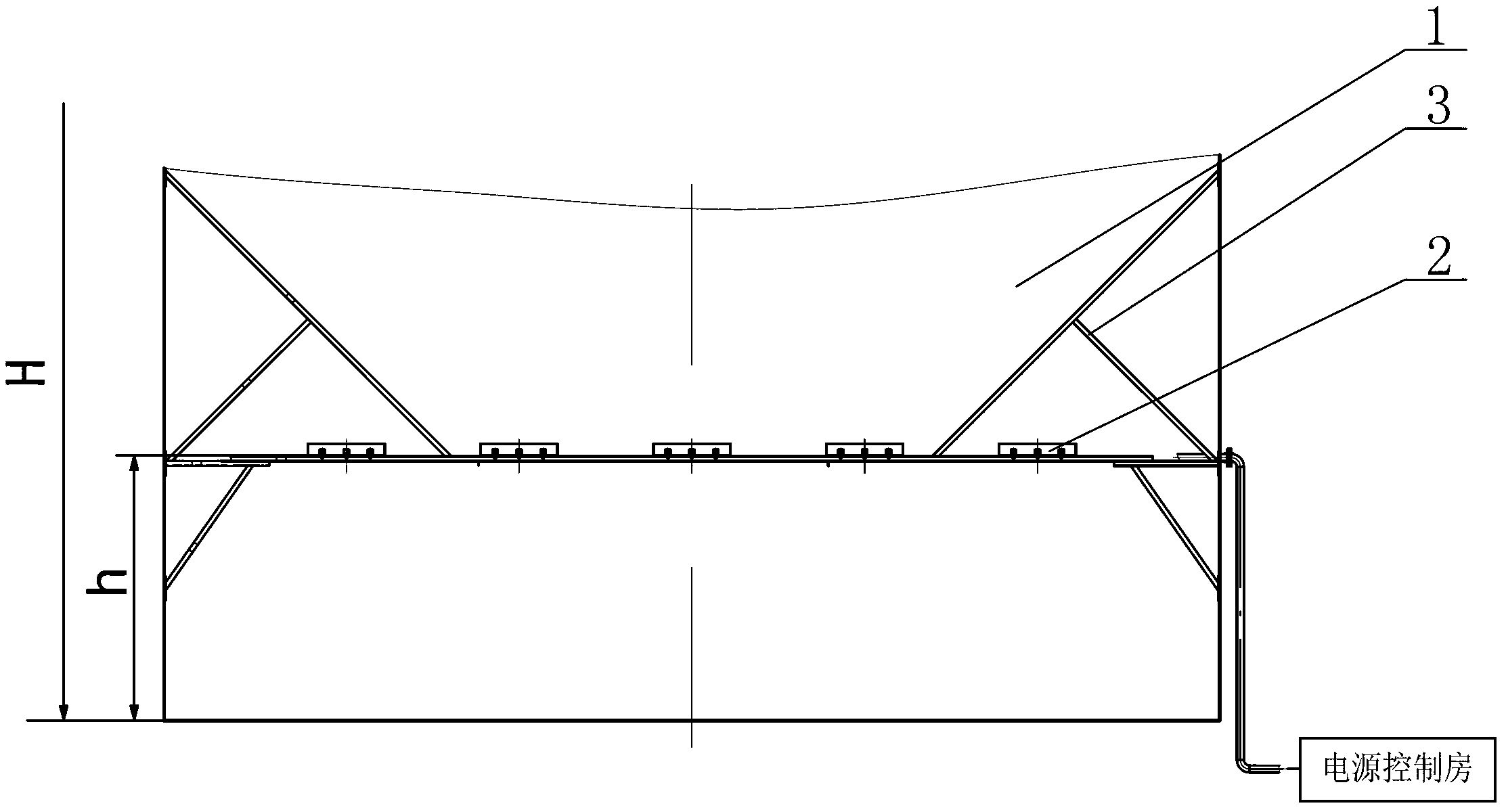

[0022] Such as figure 2 As shown, the height of the water storage tank 1 is H, and the distance between each ultrasonic transmitting vibration box 2 and the bottom of the water storage tank 1 is h, in the range of arrive between.

[0023] The interior of the water storage tank 1 is provided with an upper limit liquid level detection poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com