Real-liquid flowing electrical dewaterer evaluation device

A mobile electric dehydrator and evaluation device technology, applied in the direction of measuring devices, instruments, machine/structural parts testing, etc., can solve the problems affecting the subsequent treatment of oil products, low efficiency of centrifugal dehydration, high energy consumption of heating and dehydration, etc., to achieve structural Simplicity, increased speed, increased collision coalescence effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

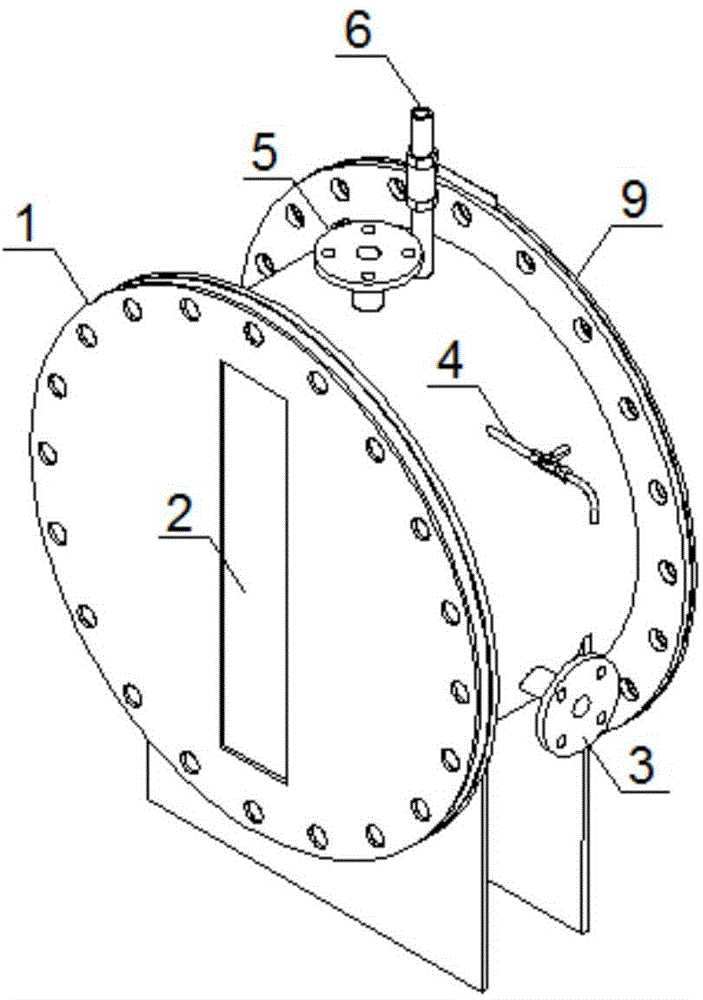

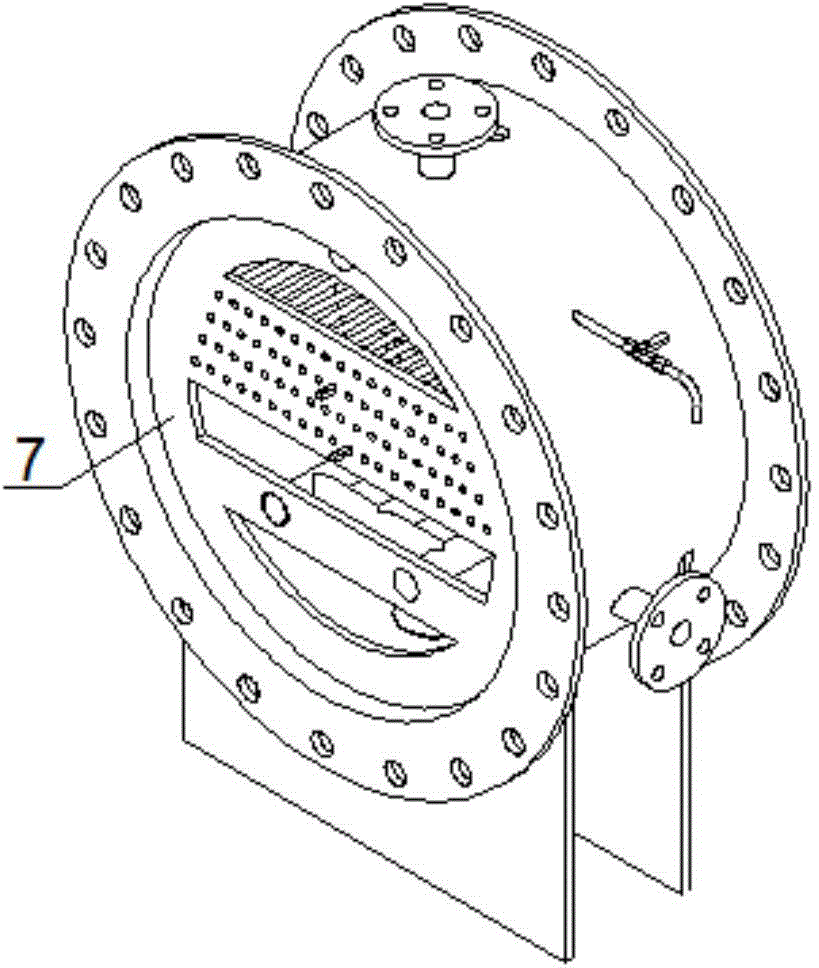

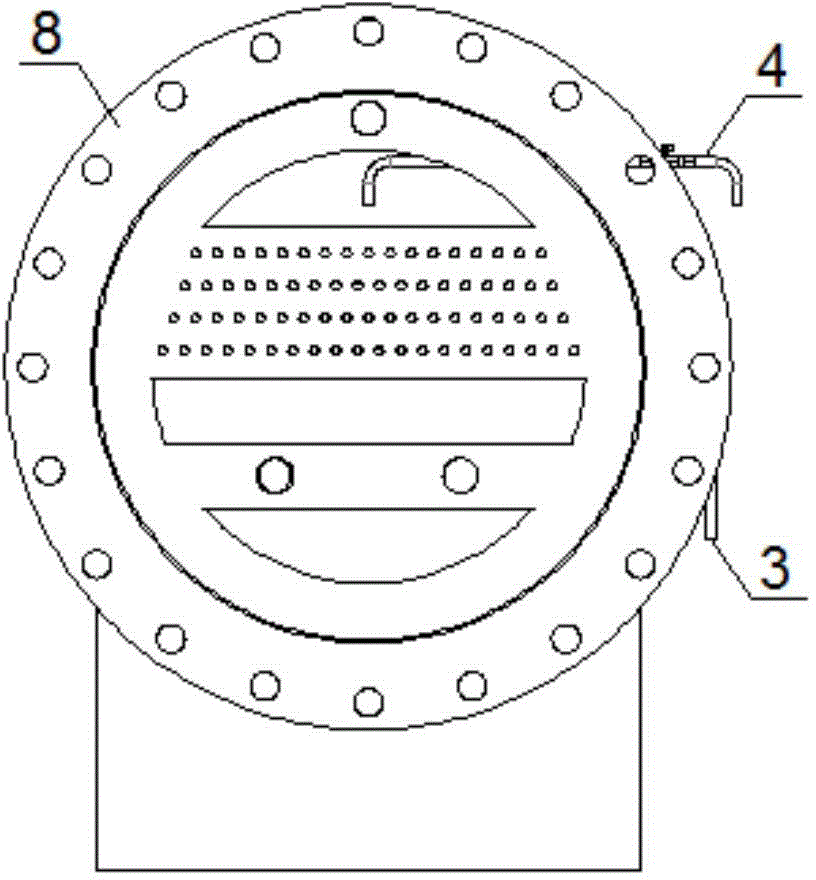

[0024] like Figure 1-7 As shown in the figure, the electric dehydrator evaluation device of the present invention is composed of a main shell 8, a liquid distribution pipe 3, a coalescing module 7, a liquid collecting pipe 5, a sampling device 4, a plexiglass end cover 2, a reinforcing plate 1, a venting Port 6, stainless steel end cover 9, etc.

[0025] The liquid distribution pipe 3 and the liquid collecting pipe 5 are connected to the main shell of the experimental prototype by welding, and the sampling device penetrates into the shell and faces the direction of incoming liquid. Liquid distribution holes are distributed on the lower side of the liquid distribution branch pipe 18 of the liquid distribution pipe 3, so that the emulsion entering the liquid distribution pipe 3 can be evenly distributed. There is a vortex breaker 14 above the water outlet 10 and is connected to the casing 8 by metal welding. The reinforcing plate 1 and the plexiglass end cover 2 are tightened...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com