Abandoned shell/nanometer Cu2O composite photocatalyst material as well as preparation and application thereof

A composite photocatalysis and shell technology, applied in catalyst activation/preparation, catalyst carrier, chemical instruments and methods, etc., can solve the problem of difficult to avoid the use and discharge of toxic organic reagents, and achieve the effect of easy sedimentation and separation and high catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

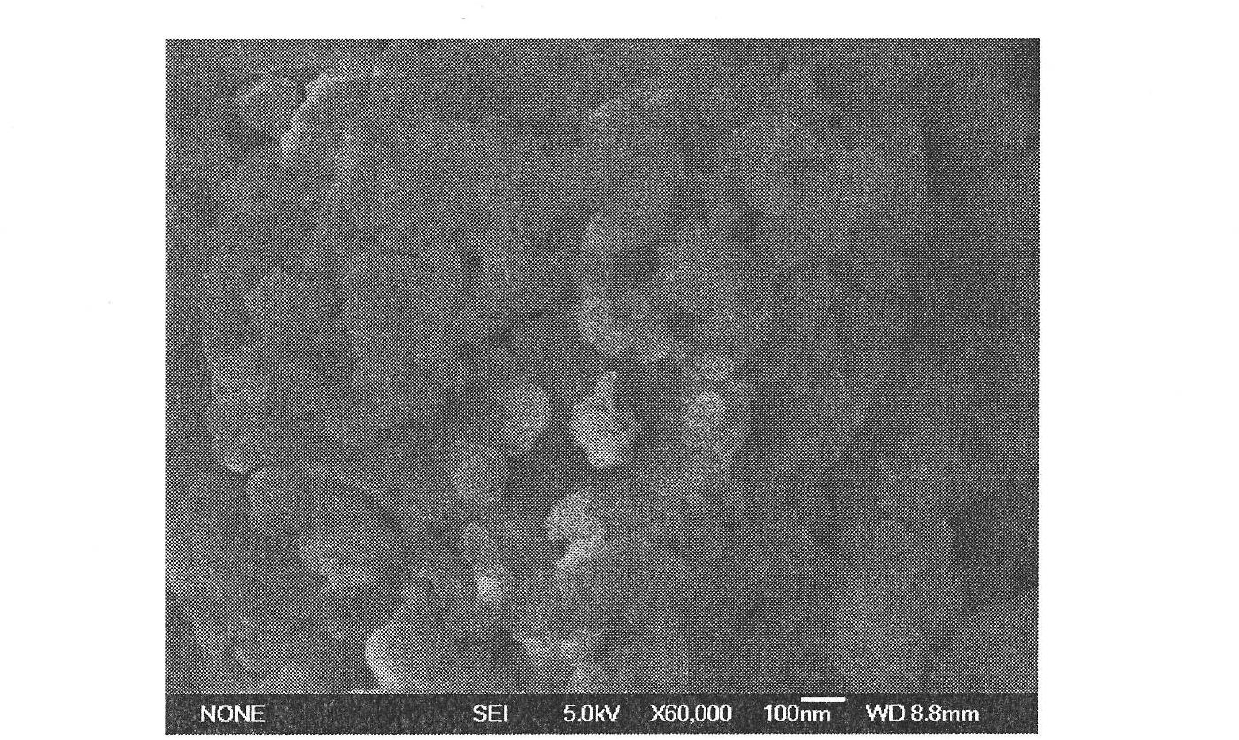

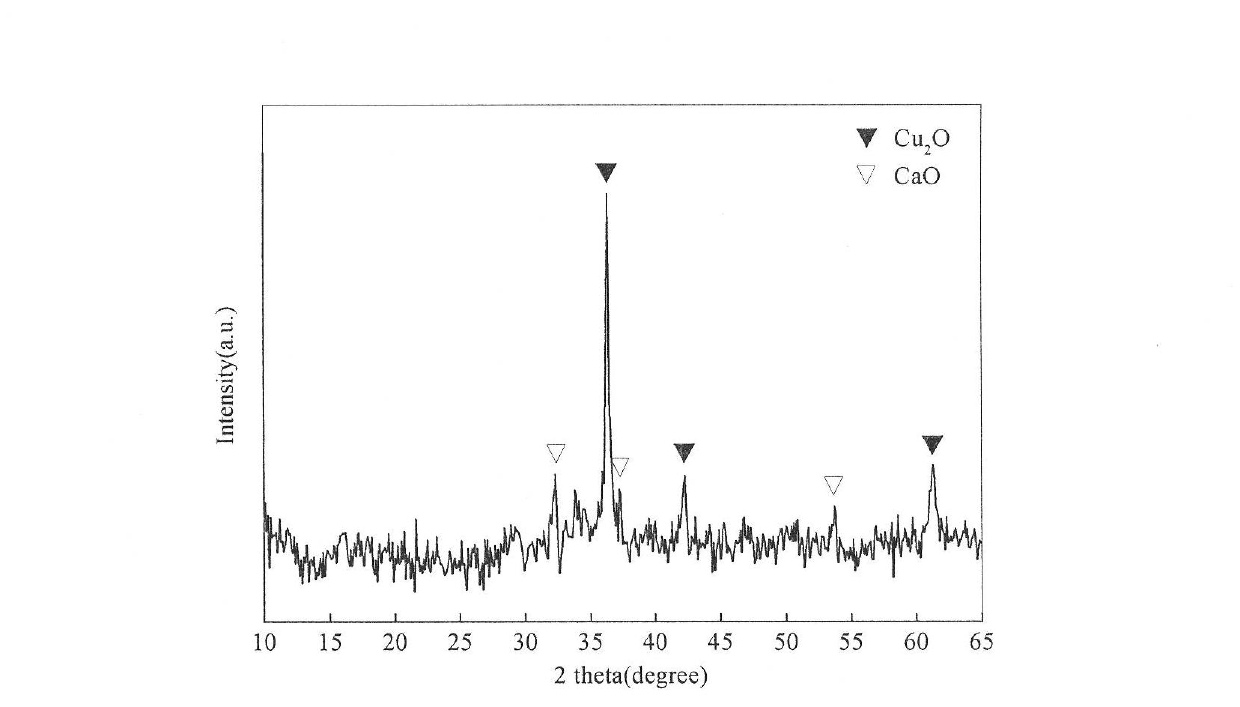

[0022] The pearl shells after pickling (soaked in dilute hydrochloric acid with a mass concentration of 0.1% for 0.5 h) and dried were calcined and activated in a muffle furnace at 1050 ° C for 2 h and crushed through a 100-mesh sieve; the NaCl concentration in the 200 mL micro-reaction system was 2.0mol / L, the concentration of sodium dodecylbenzenesulfonate is 5.0g / L, 2.0g CuCl and 2.0g activated pearl shell powder are added under magnetic stirring. The mass ratio of sodium dodecylbenzenesulfonate, CuCl and activated shell powder is 1:2:2. After continuous stirring and hydrolysis for 30min, suction filtration, ultrasonic washing (oscillation of ultrasonic cleaner for 5min), and 5 times of water washing, the obtained brown-yellow solid was dehydrated and dried at 60°C for 6h to obtain nano-Cu 2 O / shell composite photocatalytic material. Supported nano-Cu 2 The O particles are spherical and the particle size is less than 100 nm. figure 1 and figure 2 The scanning electron ...

Embodiment 2

[0025] After pickling (soaked in dilute hydrochloric acid with a mass concentration of 0.05% for 1 h) and dried, the clam shells were calcined and activated in a muffle furnace at 900 ° C for 2 h and crushed through a 100-mesh sieve; the NaCl concentration in the 100 mL micro-reaction system was 4.0 mol / L, the concentration of sodium dodecylbenzenesulfonate was 5.0g / L, 1.0g CuCl and 1.0g activated clam shell powder were added under magnetic stirring. The mass ratio of sodium dodecylbenzenesulfonate, CuCl and activated shell powder is 1:2:2. After continuous stirring and hydrolysis for 10 min, suction filtration, ultrasonic washing (oscillation with an ultrasonic cleaner for 3 min), and 5 water washings were performed, and the obtained brown-yellow solid product was dehydrated and dried at 60° C. for 6 h.

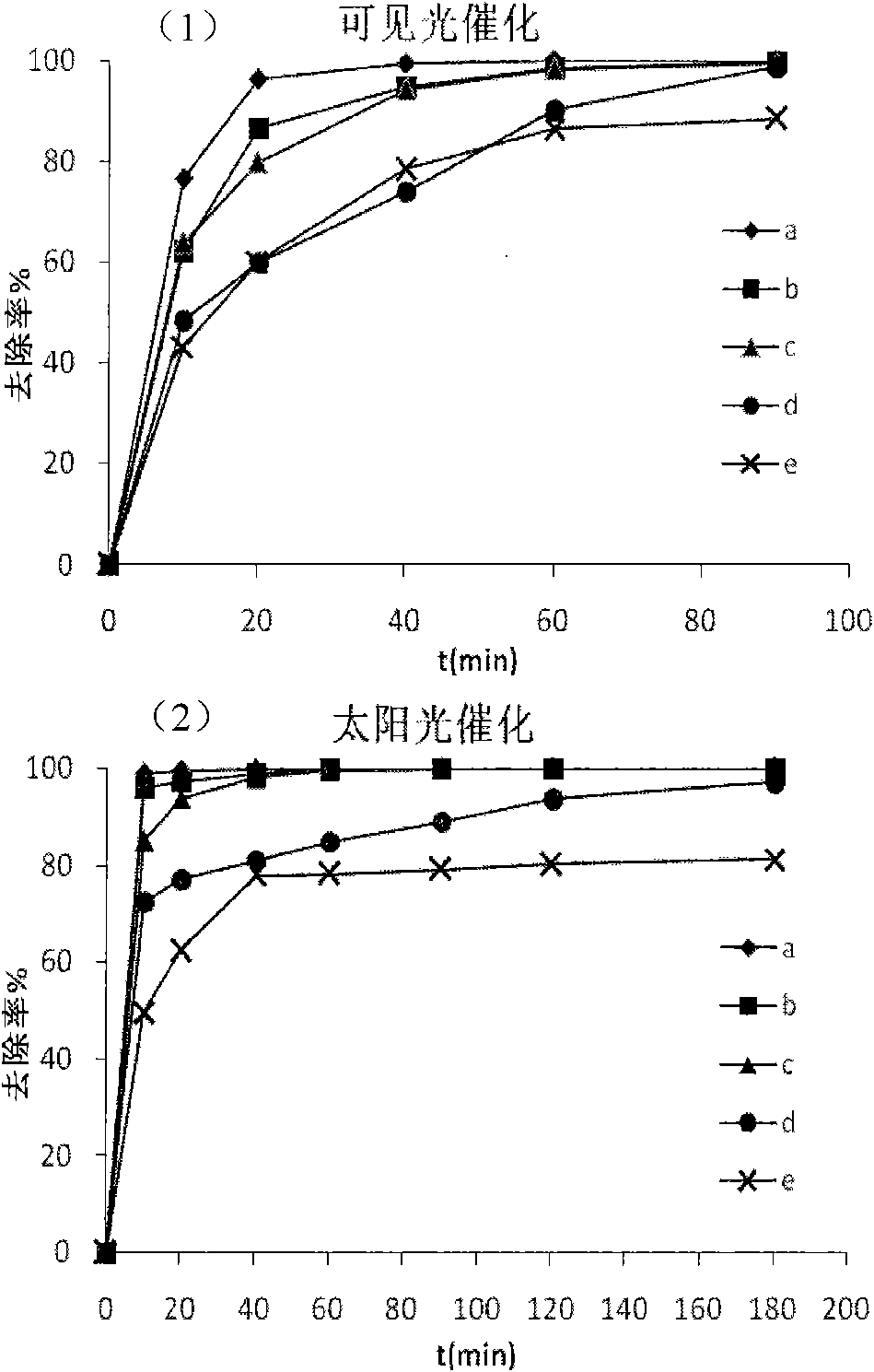

[0026] In the photocatalytic experiment, a large test tube with a diameter of 38mm was used as the reactor, and a 500w iodine-tungsten lamp was used as the light source. Aft...

Embodiment 3

[0028] The oyster shells after pickling (soaked in dilute hydrochloric acid with a mass concentration of 0.1% for 0.5h) and dried were calcined and activated in a muffle furnace at 1050°C for 2h and pulverized through a 100-mesh sieve. The NaCl concentration in the 100mL micro-reaction system was 2.0mol / L, the concentration of sodium dodecylbenzenesulfonate is 5.0g / L, 1.0g CuCl and 1.0g activated oyster shell powder are added under magnetic stirring. The mass ratio of sodium dodecylbenzenesulfonate, CuCl and activated shell powder is 1:2:2. After continuous stirring and hydrolysis for 20 min, suction filtration, ultrasonic washing (oscillation with an ultrasonic cleaner for 2 min), and 4 water washings were performed, and the obtained brown-yellow solid product was dehydrated and dried at 60° C. for 6 h.

[0029] In the photocatalytic experiment, a test tube with a diameter of 18 mm was used as the reactor, and visible light was used as the light source. Table 1 shows that un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com