Core-shell type amorphous metal oxide adsorbent, as well as preparation method and application thereof

An amorphous alloy and amorphous technology, applied in the field of core-shell amorphous metal oxide adsorbent and its preparation and application, can solve the problems of easy deactivation and aggregation, difficult settlement, difficult recovery and reuse, etc. problems, to achieve the effect of easy sedimentation separation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

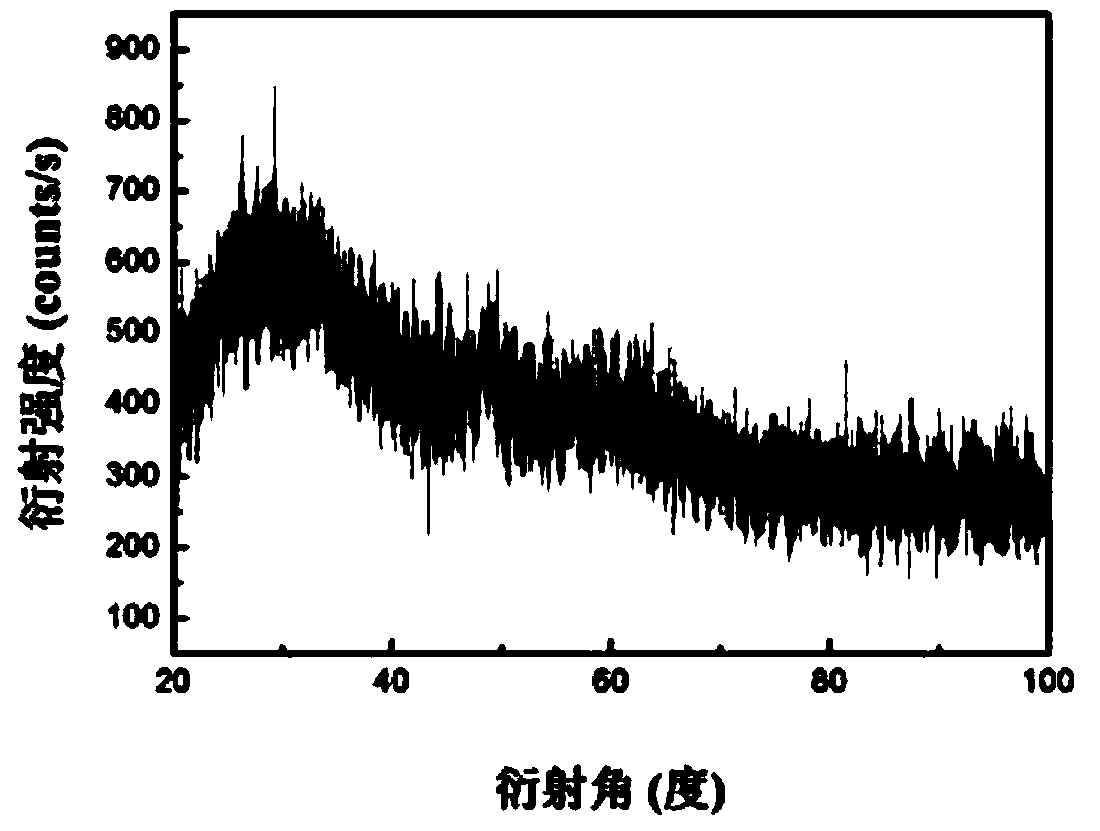

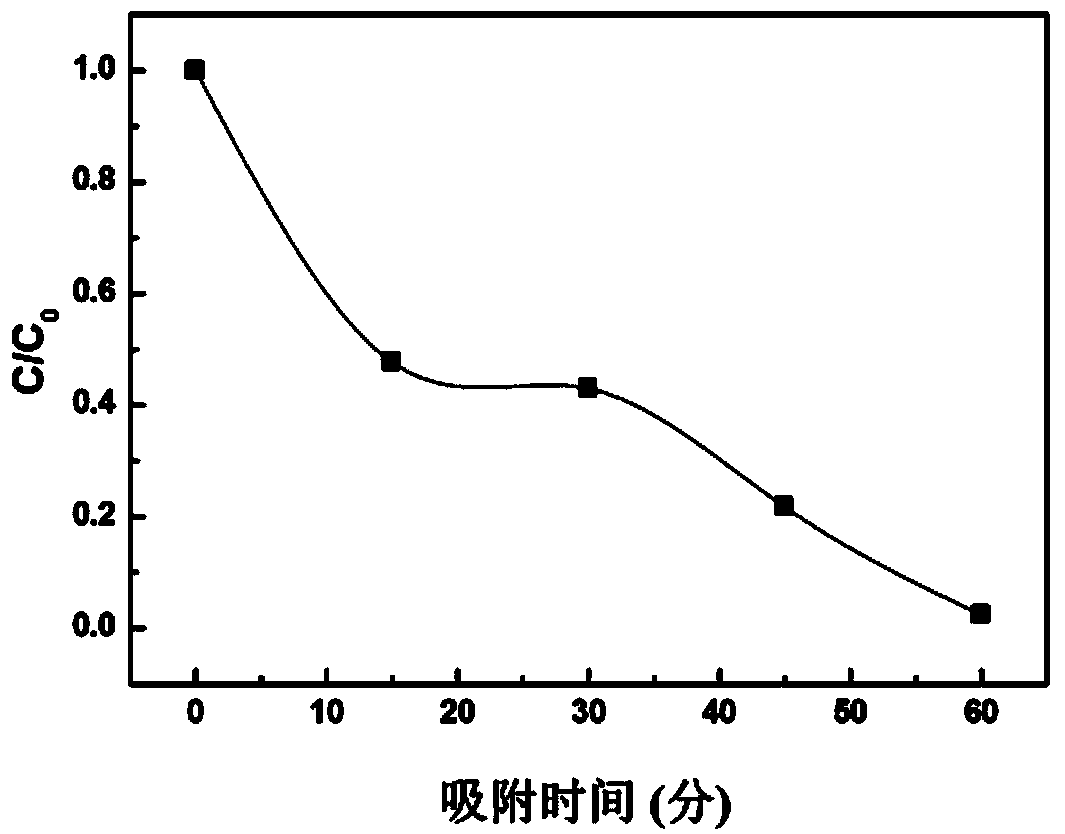

[0012] Specific embodiment 1: In this embodiment, the core-shell amorphous metal oxide adsorbent is prepared by hydrothermal method from amorphous alloy powder with a particle size of 3 μm to 50 μm, and the particle size is 3 μm to 50 μm. The chemical formula of amorphous alloy powder is Ti 40~50 Cu 40~45 Zr 5~10 Ni 0.5~5 sn 0.5~5 .

[0013] Alloys are materials with metallic properties formed by two or more metals or metals and nonmetals. In recent years, many researchers have synthesized a variety of functional nanomaterials by using alloys as raw materials and combining chemical reaction methods. Among many alloy systems, Ti-based alloys have the advantages of high specific strength, good corrosion resistance, and good biocompatibility. In addition, compared with traditional inorganic metal salts or organometallic compounds used as raw materials to prepare metal oxide adsorbents, due to the higher density of Ti alloys (about 4-5 g / cm3), the composition of Ti alloys in...

specific Embodiment approach 2

[0020] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the chemical formula of the amorphous alloy powder with a particle size of 3 μm to 50 μm is Ti 42.5 Cu 40 Zr 10 Ni 5 sn 2.5 . Others are the same as the first embodiment.

specific Embodiment approach 3

[0021]Specific embodiment three: This embodiment is a preparation method of a core-shell amorphous metal oxide adsorbent, which is specifically completed according to the following steps: 1. Put sodium hydroxide and water into a closed reaction vessel, and the The mass ratio of sodium hydroxide to water is (0.01 ~ 0.25): 1, and then add amorphous alloy powder with a particle size of 3 μm to 50 μm for reaction, and the amorphous alloy powder with a particle size of 3 μm to 50 μm The mass ratio to water is (0.01-0.5): 1, react at a temperature of 140-180°C and a pressure of 0.1MPa-5MPa for 0.5h-50h, and then cool naturally to room temperature to obtain a reaction product; Adding water to the product, adjusting the pH value of the reaction product to neutral, then standing and separating to obtain a solid product, drying the solid product to a constant weight, and obtaining a core-shell amorphous metal oxide adsorbent; in step 1 The chemical formula of the amorphous alloy powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com