Sulfur deposition agent composition and method for improving liquid phase catalytic oxidation desulphurization effect

A technology of sulfur sedimentation and composition, which is applied in the field of improving the effect of liquid-phase catalytic oxidation desulfurization, can solve the problems of increasing the amount of foam and surfactant, affecting the rapid sedimentation of sulfur particles, etc., to promote agglomeration and sedimentation, facilitate separation, and suppress sulfur foam the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of the sulfur precipitant composition of the present invention has no special requirements, as long as the flocculant, the alkylphenol polyoxyethylene ether with a polymerization degree of 8-12, the alkylphenol polyoxyethylene ether with a polymerization degree of 4-6 The ether and co-solvent can be fully mixed, and there is no special requirement on the order of adding the components.

[0023] In a preferred situation of the present invention, the sulfur precipitating agent composition further contains water, and the content of the water is such that the sulfur precipitating agent composition can form a uniform solution. Preferably, the content of water is 7-18.5 parts by weight relative to 1 part by weight of flocculant. By making the sulfur precipitant composition in the form of a solution, it can be beneficial to the use and addition of the sulfur precipitant composition in practical applications, and when used in a liquid-phase catalytic oxid...

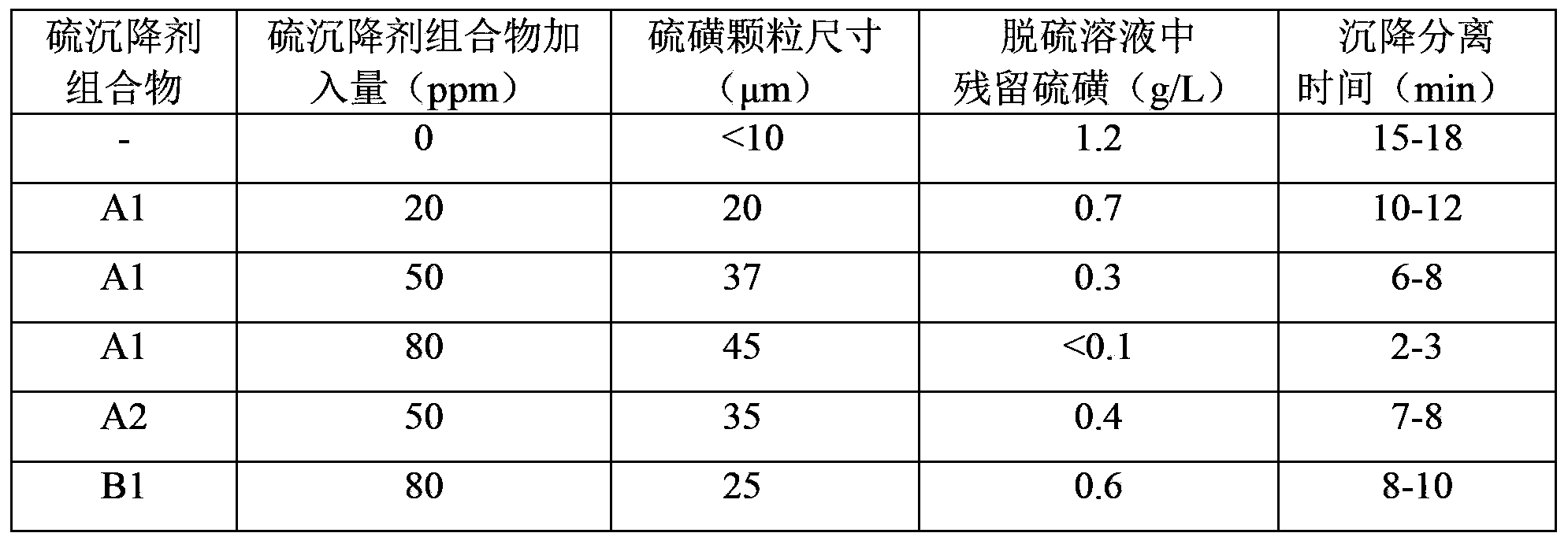

Embodiment 1

[0042] Mix 6g of nonylphenol ethoxylate (NP-10) and 0.5g of octylphenol ethoxylate (OP-4) with 3g of isopropanol, and then mix them with 8g of polyaluminum chloride (purchased from Henan Huamingshui Treatment Materials Co., Ltd.) and 82.5g of water were mixed to obtain sulfur precipitant composition A1.

Embodiment 2

[0046] A sulfur sedimentation agent composition was prepared according to the method of Example 1, except that the flocculant polyaluminum chloride was replaced by sorbitan of the same weight. The sulfur precipitating agent composition A2 was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com