Energy-saving environment-friendly efficient water drainage and silt removal device for flue gas desulfurization chimney

An energy-saving and environmentally friendly chimney technology, which is applied in the treatment of gaseous effluent wastewater, flocculation/sedimentation water/sewage treatment, and combustion product treatment, can solve the problems of chimney air tightness, deterioration of the operating environment, and high risk To achieve the effect of keeping the chimney unobstructed, easy to promote, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

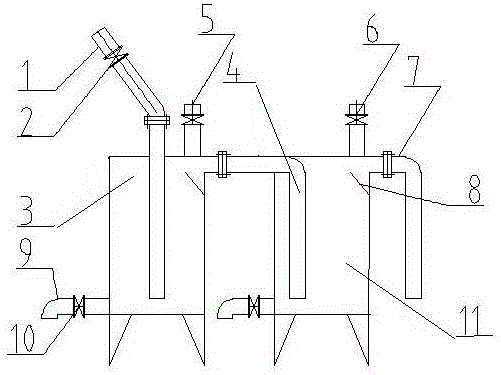

[0025] Further illustrate the present invention below in conjunction with accompanying drawing. These descriptions are for better expressing and understanding the beneficial effects of the present invention, rather than limiting the present invention.

[0026] Such as figure 1 As shown, this high-efficiency flue gas desulfurization chimney drainage and silt discharge device of the present invention includes a diversion pipe 1 for sewage discharge at the bottom of the high-altitude chimney. , and vertically stretch into the tank body simultaneously, the top of the drain tank has an upper conduit 4 connected with the top of the drain tank two and vertically stretches into the inside of the drain tank two, and the top of the two drain tanks has a water-adding pipe 5 and a ball valve 6. The outlet of the upper drainage pipe 7 of the drainage tank two is located at the overflow port, and the outlet reaches the ground collection ditch. The drainage baffles 8 of the two drain tanks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com