Low-grade heavy-oil hydrotreatment process for maximally improving catalyst utilization rate

A low-quality heavy oil and hydrotreating technology, applied in the field of hydrogenation, can solve the problems of short operation cycle, and achieve the effect of slowing down the pressure drop, slowing down the rising speed, and prolonging the operation cycle of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Embodiment 1 (the described concentration % is mass %)

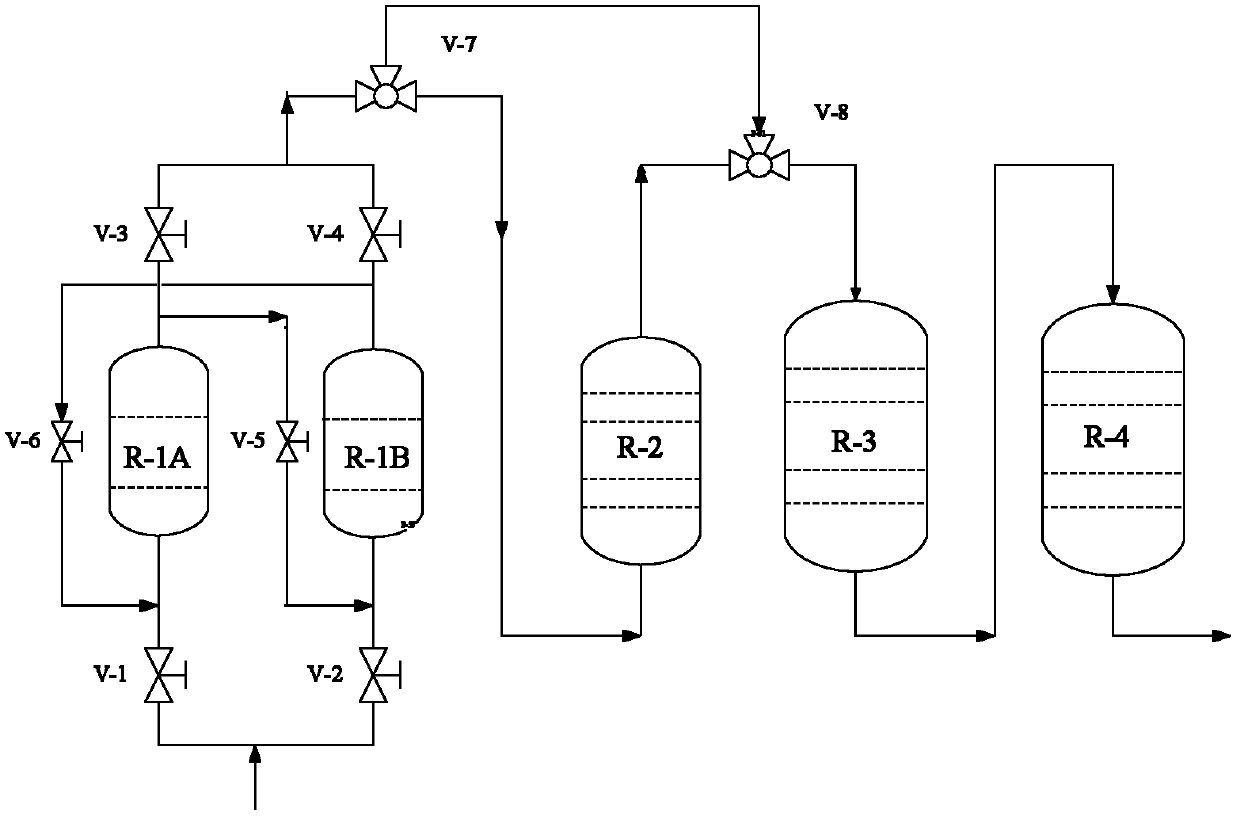

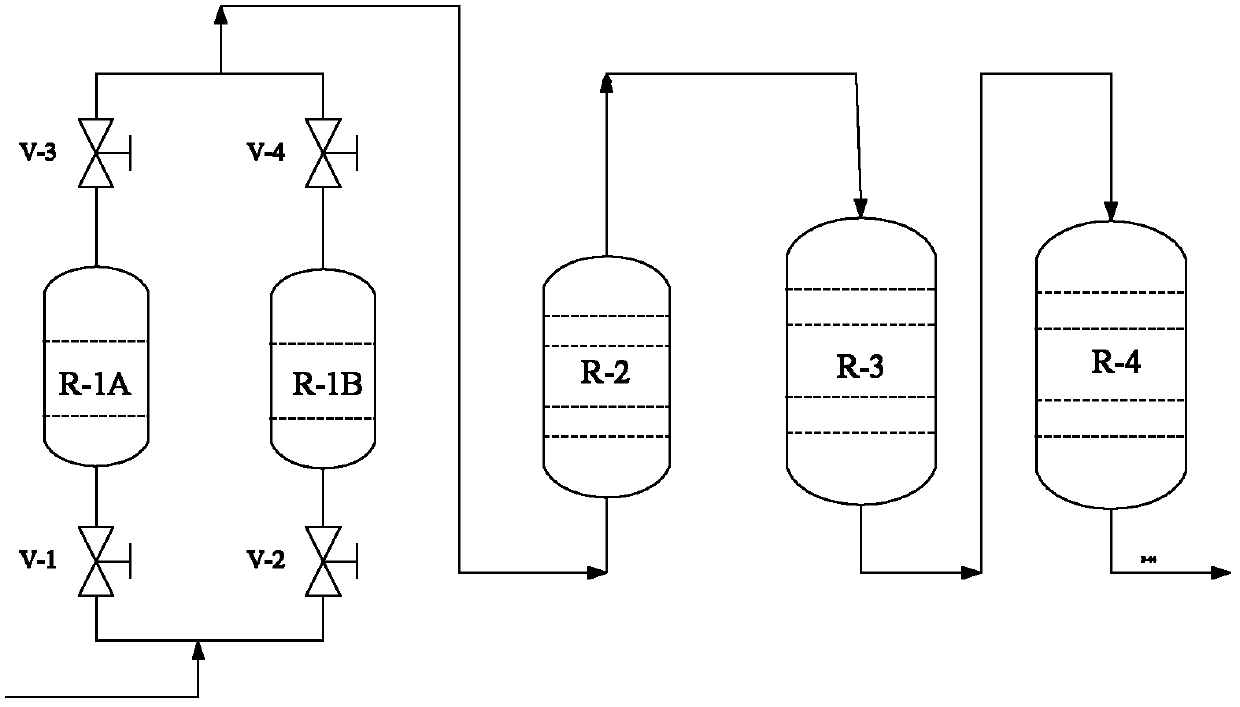

[0069] Example 1 uses figure 1 The hydrogenation process combination shown includes 5 reactors, including 2 upflow de-iron and decalcification reactors, 1 upflow demetallization reactor, 1 desulfurization reactor and 1 denitrogenation reactor.

[0070] The upflow de-iron and decalcification reactor is filled with a hydrogenation de-iron and decalcification agent, numbered DFC-1#, and the preparation method of the catalyst is as follows:

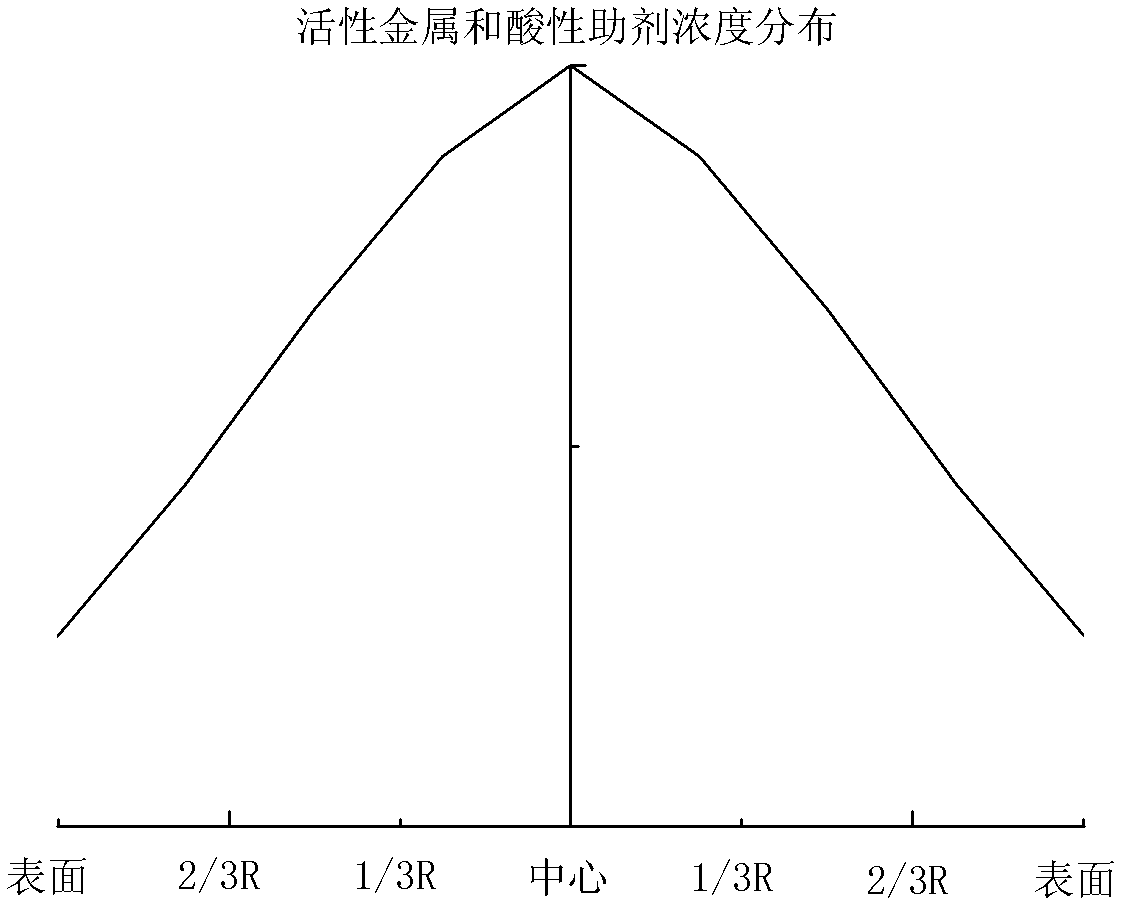

[0071] In this embodiment, the hollow gear shape Al 2 o 3 As a carrier, the catalyst with active metal components of Mo and Ni was prepared by saturated spray-dipping method.

[0072] Weigh 150g of Al with a water absorption rate of 1.10ml / g 2 o 3 Carrier, spray immersion 50ml containing 4.3g ammonium molybdate (containing MoO 3 82%, Beijing Chemical Reagent Company) impregnating solution, in the process of spraying and soaking, drip 115ml concentration at a uniform speed a...

Embodiment 2

[0098] The hydrogenation process combination in the embodiment includes 5 reactors, including 2 upflow de-iron and decalcification reactors, 1 upflow demetallization reactor, 1 desulfurization reactor and 1 denitrogenation reactor.

[0099]The upflow fixed-bed de-iron and decalcification reactor is filled with a hydrode-iron and decalcification catalyst, numbered DFC-2#, and the preparation method is as follows:

[0100] Select Pentagon Al 2 o 3 As a carrier, weigh 150g of Al with a water absorption rate of 1.10ml / g 2 o 3 Carrier, spray immersion 50ml containing 8.6g ammonium molybdate (containing MoO 3 82%, Beijing Chemical Reagent Company) and the ammonia solution of 3.10g nickel nitrate (containing NiO25.2%, Beijing Chemical Reagent Company), in the process of spraying, dripping 115ml concentration at a constant speed is the ammonia solution of 15% in the above-mentioned solution and Stir, and spray and soak while dripping, and spray and soak in 5 minutes. After homoge...

Embodiment 3

[0108] The hydrogenation process combination in the embodiment includes 5 reactors, including 2 upflow de-iron and decalcification reactors, 1 upflow demetallization reactor, 1 desulfurization reactor and 1 denitrogenation reactor.

[0109] The upflow fixed-bed iron and decalcification reactor is filled with a hydrodeferrification and decalcification catalyst DFC-1#, and the catalyst is the same as in Example 1.

[0110] The upflow demetallization reactor is filled with a hydrodemetallization agent DM-2#, and the catalyst is the same as in Example 1.

[0111] The desulfurization reactor is filled with a hydrodesulfurization agent, numbered DS-2# respectively. Catalyst is with embodiment 1.

[0112] The fixed-bed denitrogenation reactor is filled with a hydrodenitrogenation catalyst DN-2#, the catalyst is the same as in Example 2.

[0113] The raw material oil C used in the evaluation is a residual oil raw material, and its properties are shown in Table 3. The operation of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com