Grading method of heavy oil hydrotreating catalyst

A heavy oil hydrogenation and catalyst technology, applied in chemical instruments and methods, hydrocarbon oil treatment, petroleum industry, etc., can solve the problem of poor hydrogenation saturation ability of polycyclic aromatic hydrocarbons, low content of hydrogenation active components, and insufficient hydrogenation conversion ability Strong and other problems, to achieve the effect of long service life, high denitrification activity and stability, and slow down the deactivation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

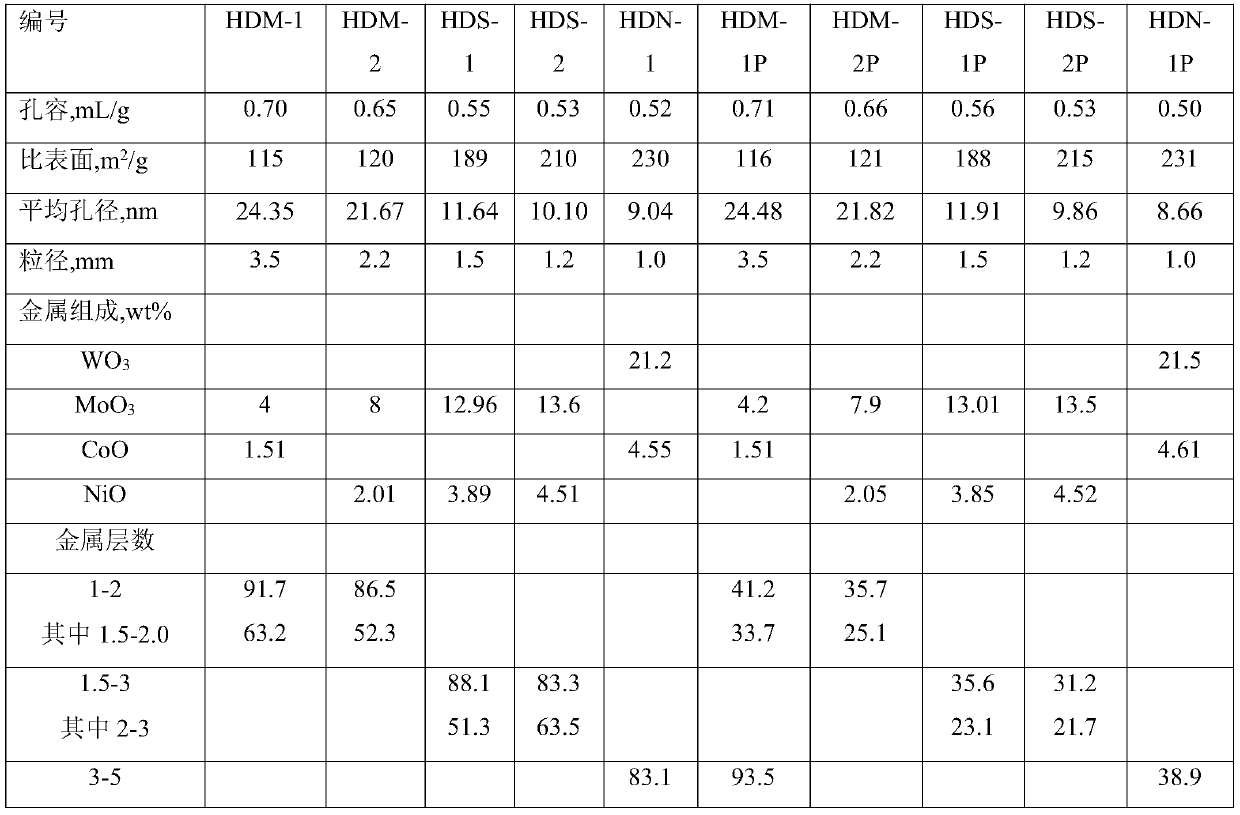

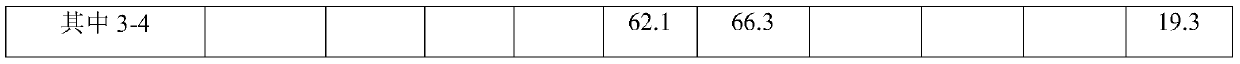

[0059] This example shows the preparation process of a graded combination of catalysts.

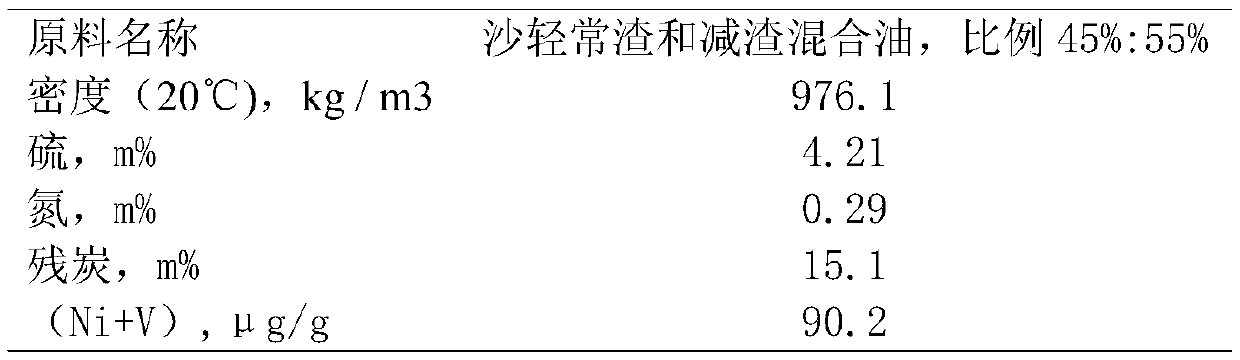

[0060] The following catalyst gradation assembly scheme is adopted, and several catalysts are loaded in the reactor, and the bed is filled with hydrodemetallization catalyst HDM-1, hydrodesulfurization catalyst HDS-1 and hydrodenitrogenation catalyst HDN-1 from top to bottom , the mass proportions added are respectively 45%, 20%, and 35%.

[0061] Hydrodemetallization catalyst HDM-1 has an average pore size of 24.35nm and a particle size of 3.5mm; hydrodesulfurization catalyst HDS-1 has an average pore size of 11.64nm and a particle size of 1.5mm; The average pore diameter is 9.04nm, and the particle diameter is 1.0mm. When the catalyst is loaded along the flow direction, the catalyst activity gradually increases, the pore size gradually decreases, the particle size gradually decreases, and the porosity gradually decreases.

[0062] Then, wet vulcanization is adopted, and the vulcanizin...

Embodiment 2

[0070] This example shows the preparation process of a graded combination of catalysts.

[0071] The following catalyst grading assembly scheme is adopted, and several catalysts are loaded in the reactor, and the bed is filled with hydrodemetallization catalyst HDM-2, hydrodesulfurization catalyst HDS-2 and hydrodenitrogenation catalyst HDN-1 respectively from top to bottom , the mass proportions added are respectively 35%, 20%, and 45%.

[0072] Hydrodemetallization catalyst HDM-2 has an average pore size of 21.67nm and a particle size of 2.2mm; hydrodesulfurization catalyst HDS-2 has an average pore size of 10.10nm and a particle size of 1.2mm; The average pore diameter is 9.04nm, and the particle diameter is 1.0mm. When the catalyst is loaded along the flow direction, the catalyst activity gradually increases, the pore size gradually decreases, the particle size gradually decreases, and the porosity gradually decreases.

[0073] Then, wet vulcanization is adopted, the vul...

Embodiment 3

[0082] This example shows the preparation process of a graded combination of catalysts.

[0083] The following catalyst grading assembly scheme is adopted. Several catalysts are loaded in the reactor, and the bed is filled with hydrodemetallization catalysts (HDM-1, HDM-2, the mass ratio is 1:1) and hydrogenation catalysts from top to bottom. Desulfurization catalyst (HDS-1, HDS-2, the mass ratio is 1:1) and hydrodenitrogenation catalyst HDN-1P, the mass proportions added are 30%, 45%, and 25%, respectively.

[0084] The average pore diameter of the hydrodemetallization catalyst HDM-1 is 24.35nm, and the particle size is 3.5mm; the average pore diameter of the hydrodemetallization catalyst HDM-2 is 21.67nm, and the particle size is 2.2mm; The average pore size is 11.64nm and the particle size is 1.5mm; the average pore size of the hydrodesulfurization catalyst HDS-2 is 10.10nm and the particle size is 1.2mm; the average pore size of the hydrodenitrogenation catalyst HDN-1 is 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com