Hydrogenation technological method for reducing skimming of catalyst

A catalyst and catalyst bed technology, applied in chemical instruments and methods, petroleum industry, chemical/physical processes, etc., can solve problems such as complex operation, and achieve the effects of improving economic benefits, simple methods, and increasing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

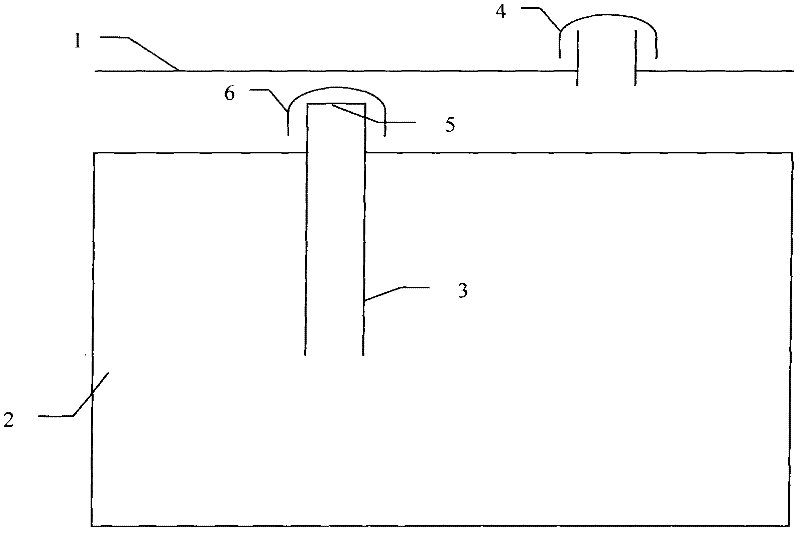

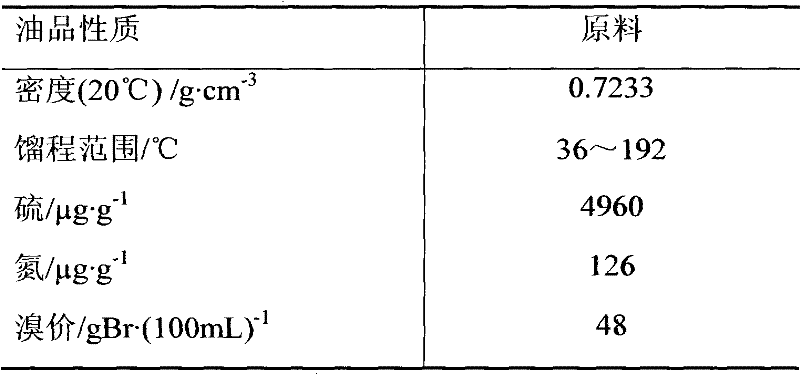

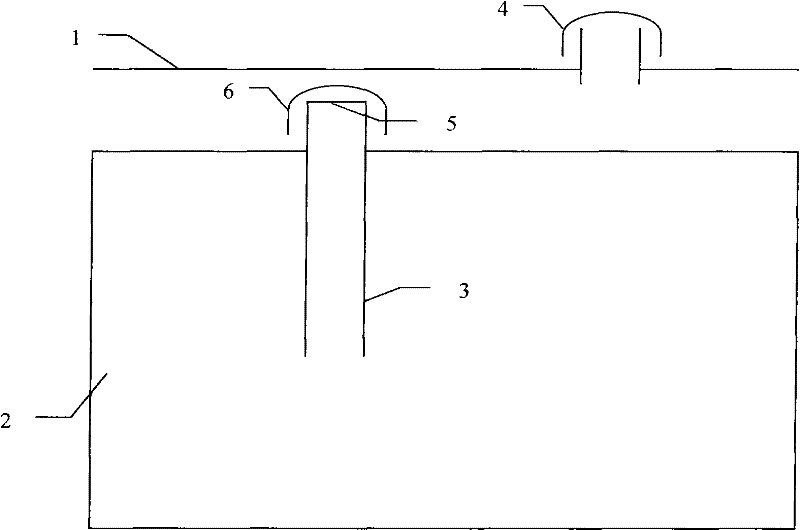

[0031] FHRS-1 (hydrogenation silicon scavenger), FZC-102B (hydrogenation protection agent) and FH-40C (main hydrorefining catalyst) developed and produced by Fushun Petrochemical Research Institute are used. according to figure 1 As shown in the schematic structure, the reactor is equipped with two catalyst beds, the first catalyst bed is filled with FHRS-1, and the long center pipe on the gas-liquid distribution plate extends downward to the middle of the bed. The second catalyst bed is filled with FZC-102B and FH-40C. The properties of raw oil are shown in Table 1, and the process conditions and product properties after 100 days of operation are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com