Hydrogenation method for catalytic cracking heavy cycle oil

A technology for catalytic cracking of heavy oil and catalysts, which is applied in the fields of hydroprocessing, petroleum industry, and hydrocarbon oil treatment. It can solve the problems of catalyst bed clogging, achieve the effects of improving cracking performance, efficient utilization, and reducing SOx emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

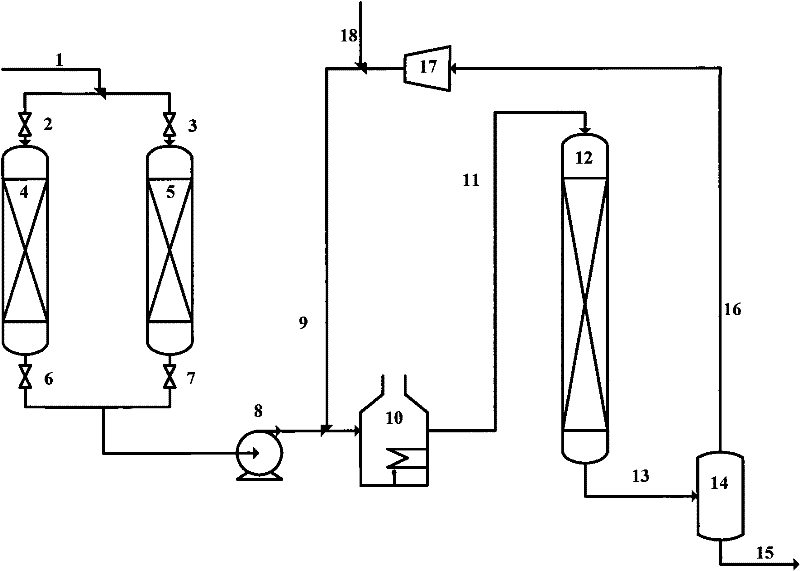

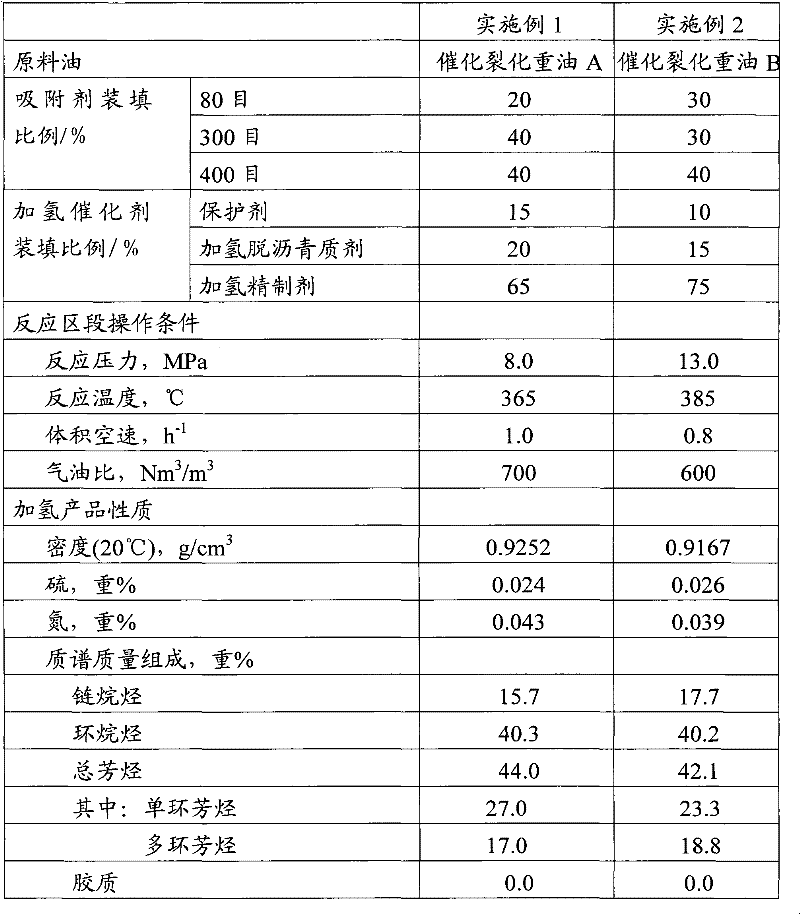

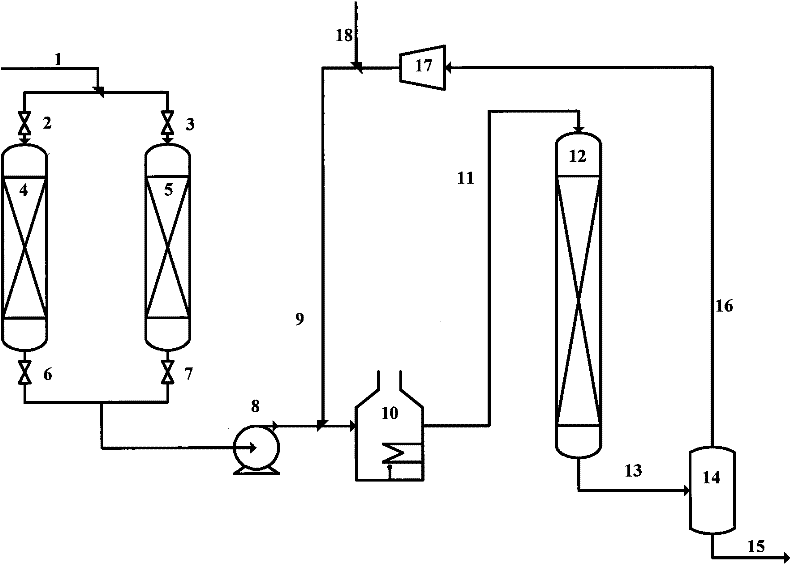

[0033] Catalytic cracking heavy oil A first passes through the protection reactor A, contacts with the adsorbent to filter out most of the catalytic cracking catalyst powder, is pressurized by the raw material oil pump and mixed with hydrogen, and then enters the heating furnace, and then enters the hydrogenation reactor after heating, which is followed by hydrogenation protection. agent, hydrodeasphalting agent, and hydrofining agent. The oil produced by hydrogenation is separated from gas and liquid by a high pressure separator, the liquid product is discharged from the device, and the gas is compressed by the compressor and mixed with new hydrogen and then mixed with the raw material oil. When the protection reactor A reaches the saturated adsorption capacity, blockage occurs, and the pressure difference rises, the protection reactor B is cut into the system, and the protection reactor A is cut out of the system at the same time, and the adsorbent in it is replaced.

[0034...

Embodiment 2

[0037] Catalytic cracking heavy oil B first passes through the protection reactor A, contacts with the adsorbent to filter out most of the catalytic cracking catalyst powder, is pressurized by the raw material oil pump and mixed with hydrogen, and then enters the heating furnace, and then enters the hydrogenation reactor after heating, and is followed by hydrogenation protection. agent, hydrodeasphalting agent, and hydrofining agent. The oil produced by hydrogenation is separated from gas and liquid by a high pressure separator, the liquid product is discharged from the device, and the gas is compressed by the compressor and mixed with new hydrogen and then mixed with the raw material oil. When the protection reactor A reaches the saturated adsorption capacity, blockage occurs, and the pressure difference rises, the protection reactor B is cut into the system, and the protection reactor A is cut out of the system at the same time, and the adsorbent in it is replaced.

[0038] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com