Non-ionic self-emulsifying aqueous epoxy hardener and preparation method and application thereof

A water-based epoxy, non-ionic technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of amino hydroxyl compounds, etc., can solve the problem of poor leveling effect of water-based coatings, poor self-emulsification effect, curing agent Problems such as large molecular weight, to achieve good flexibility and surface activity, good emulsifying effect, and good emulsifying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] 1. Preparation of biepoxy compound:

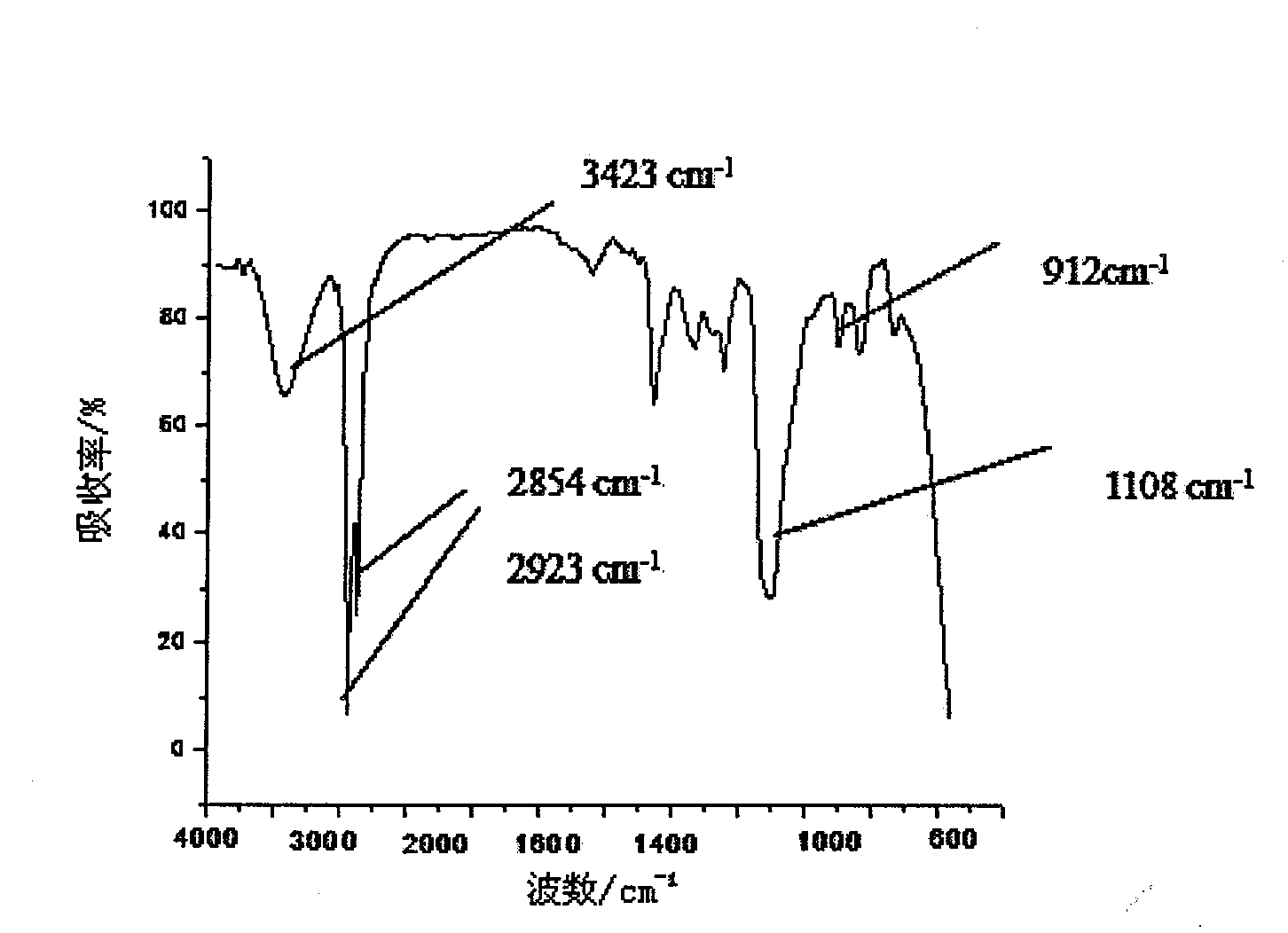

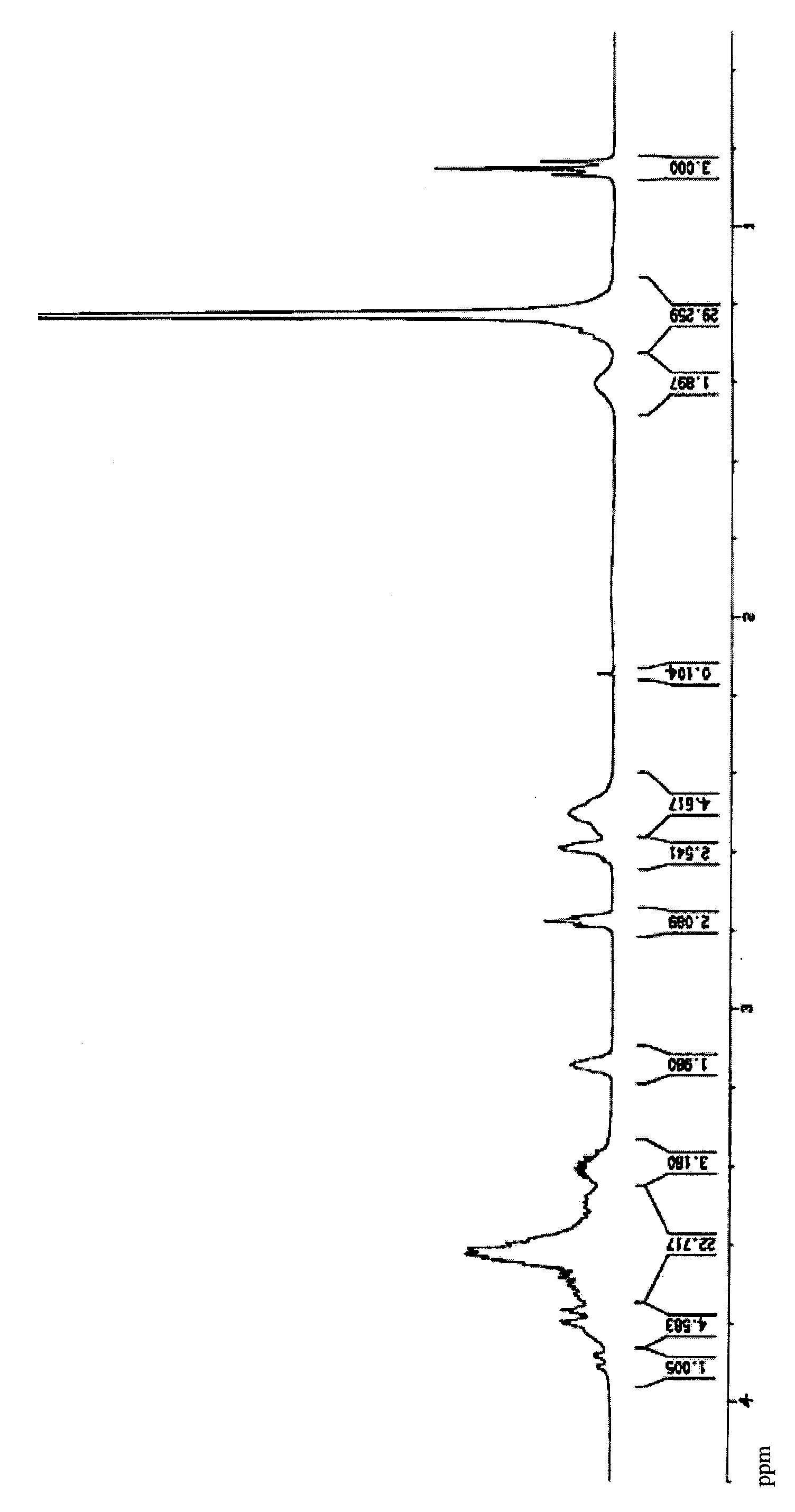

[0067] In a four-necked flask filled with nitrogen, equipped with a stirrer, a thermometer, a reflux tube, and a constant pressure funnel, add 0.24 moles of SY-669 (ethylene glycol bisglycidyl ether), raise the temperature to 65°C, and add 0.1 moles of Octadecylamine was dissolved in 40 g of propylene glycol methyl ether, placed in a constant pressure funnel, and then slowly dropped into the flask. Control the dropwise addition within 1 to 1.5 hours, then raise the temperature to 70°C, react for about 3 to 4 hours, and determine the end of the reaction by the hydrochloric acid acetone method. Take out the product, cool the product, the infrared spectrum of the product is as follows figure 1 As shown, the NMR spectrum is as figure 2 Shown.

[0068] Such as figure 1 As shown, it can be seen from the structural formulas of the two raw materials that both ends of the ethylene glycol and glycidyl ether molecules have an epoxy group (the c...

Embodiment 2

[0082] 1. Preparation of biepoxy compound:

[0083] In a four-necked flask filled with nitrogen, equipped with a stirrer, a thermometer, a reflux condenser, and a constant pressure funnel, add 0.24 moles of SY-669 (ethylene glycol bisglycidyl ether), raise the temperature to 65°C, and add 0.1 moles of The distilled tallow-based primary amine was dissolved in 40 g of propylene glycol methyl ether, placed in a constant pressure funnel and slowly dropped into the flask. Control the dropwise addition within 1 to 1.5 hours, then raise the temperature to 70°C, react for about 3 to 4 hours, and determine the end of the reaction by the hydrochloric acid acetone method. The product was taken out and cooled. Its structural formula is:

[0084]

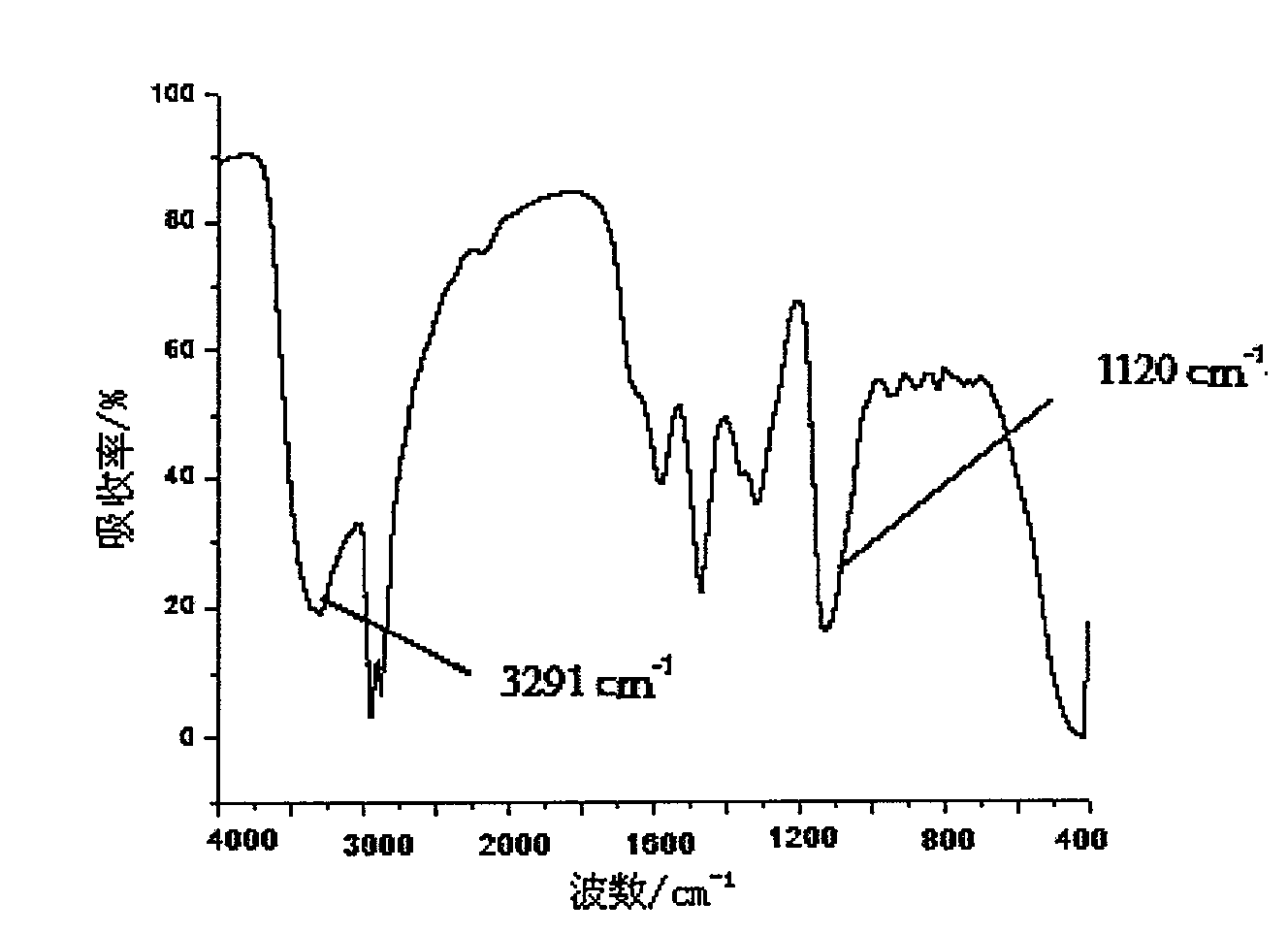

[0085] 2. Preparation of non-ionic self-emulsifying waterborne epoxy curing agent:

[0086] Dissolve 0.24 moles of triethylenetetramine in 20 g of propylene glycol methyl ether solution, put it into a four-necked flask filled with nitrogen, equipped...

Embodiment 3

[0095] 1. Preparation of biepoxy compound:

[0096] In a four-necked flask filled with nitrogen, equipped with a stirrer, a thermometer, a reflux condenser, and a constant pressure funnel, add 0.25 moles of butanediol diglycidyl ether, raise the temperature to 65°C, and dissolve 0.1 moles of dihydrogenated tallow amine The tetradecylamine solution in 40 g of toluene is placed in a constant pressure funnel, and then slowly dropped into the flask. Control the dropwise addition within 1 to 1.5 hours, then raise the temperature to 70°C, react for about 3 to 4 hours, and determine the end of the reaction by the hydrochloric acid acetone method. The product was taken out and cooled to room temperature. The structural formula of the resulting product is as follows:

[0097]

[0098] 2. Preparation of epoxy curing agent:

[0099] Dissolve 0.3 mole of triethylenetetramine in 40 g of propylene glycol methyl ether solution, put it into a four-necked flask filled with nitrogen, equipped with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com