Plugging bearing material for petroleum drilling, and preparation method and application thereof

A technology for oil drilling and pressure-bearing agent, applied in chemical instruments and methods, earth-moving drilling, wellbore/well components, etc., can solve the problems of poor construction safety, repeated leakage, early thickening, etc. The effect of pumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

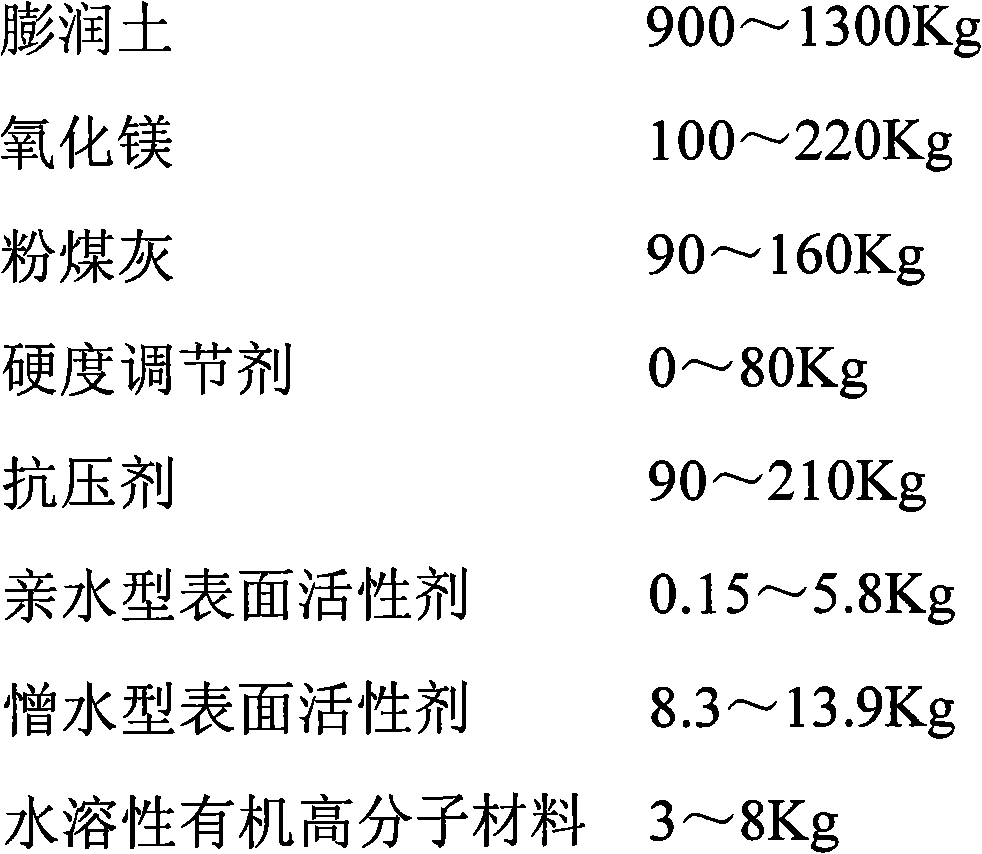

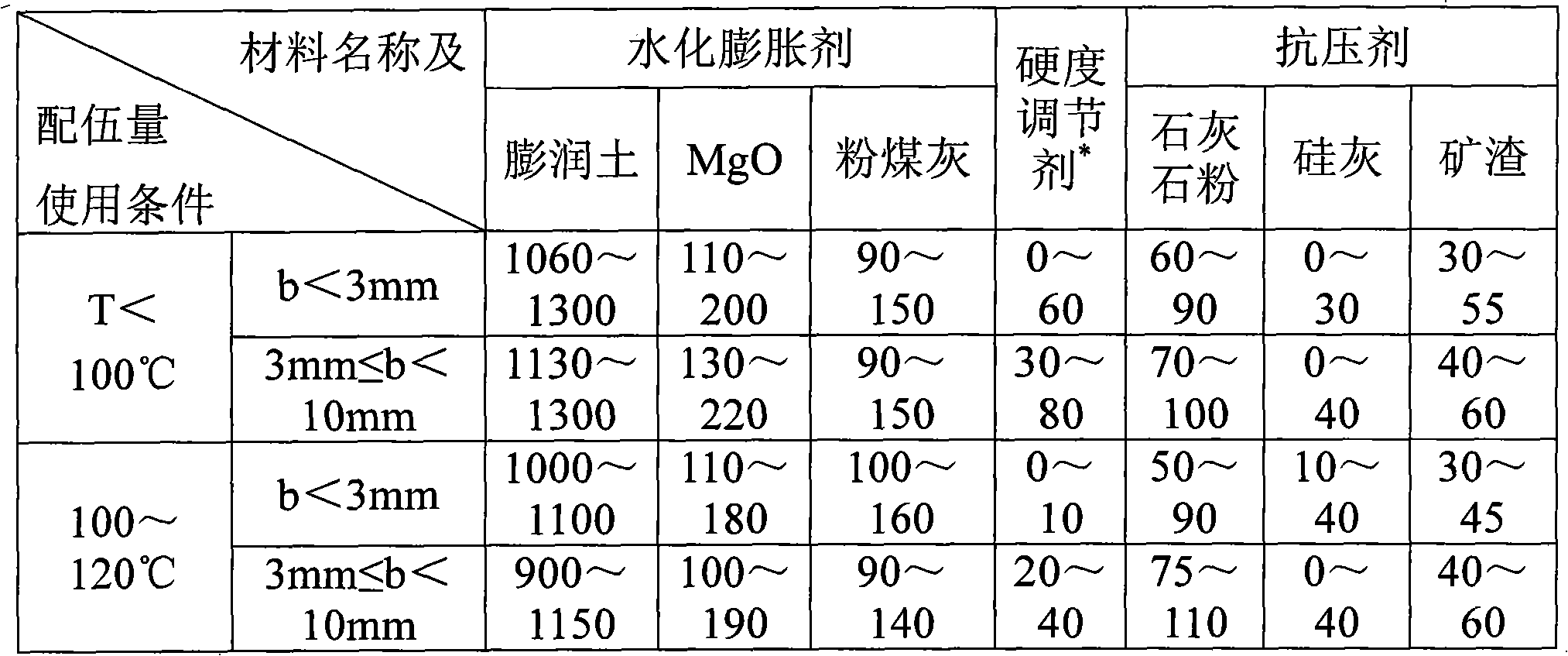

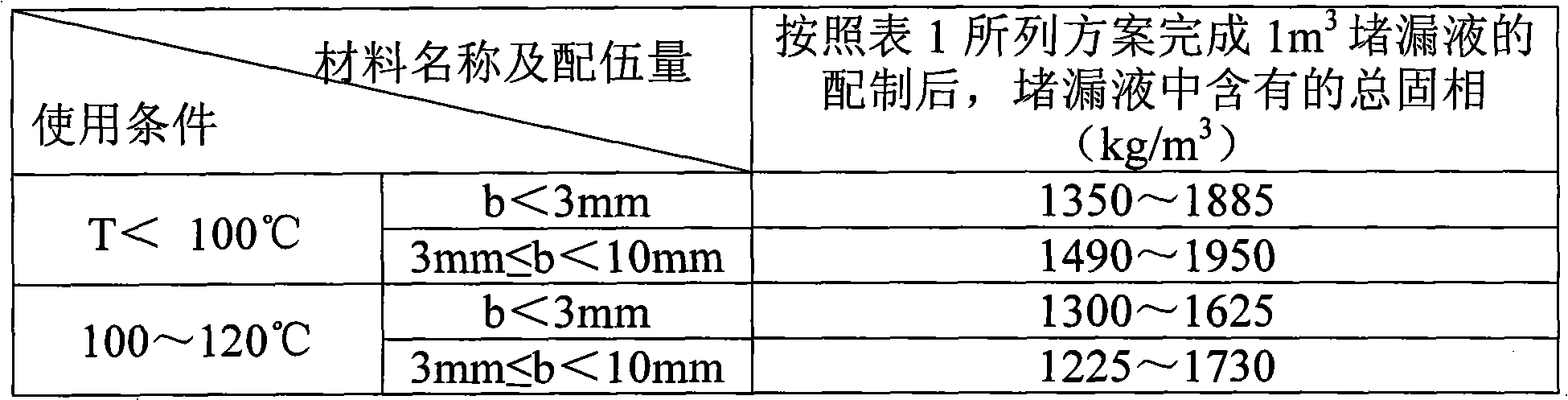

[0116]Material compatibility plan: powder material (hydration expansion agent + anti-pressure agent) + mineral oil + surfactant complex agent + polymer solution, the specific compatibility is as follows:

[0117] (1) Measure 100ml of diesel oil, add OA 0.95g, SP-850.15g to dissolve;

[0118] (2) Take a small amount of water and add K-120.28g to dissolve, then add to the solution obtained in step (1);

[0119] (3) Add 110 g of bentonite, 12 g of MgO, 10 g of fly ash, 7 g of limestone powder, and 3 g of slag in sequence to the solution obtained in step (2), and stir for 1 hour.

[0120] (4) Measure 100ml of water, add 0.5g of polyacrylamide, after complete dissolution, add 3g of walnut shells with a particle size range of 0.1-5mm to form a stable dispersion. Use the polymer dispersion with a rated displacement of 20-30m 3 / h small centrifugal pump evenly and slowly added to the solution obtained in step (3), and continued to stir for 30 minutes until a stable mixed fluid was f...

Embodiment 2

[0124] Material compatibility scheme: powder material (hydration expansion agent + hardness modifier + anti-pressure agent) + mineral oil + surfactant complex agent + polymer glue (that is, polymer aqueous solution), the specific compatibility is as follows:

[0125] (1) Measure 100ml of diesel oil, add OA 1g, EO-500.13g to dissolve;

[0126] (2) A small amount of water was added to G-2630.35g to dissolve, and then added to the solution obtained in step (1);

[0127] (3) add 117g bentonite, 15g MgO, 13g fly ash, 5g cement, 8g limestone powder, 4g slag, 2g silica fume successively in the solution that step (2) obtains, stir 1 hour;

[0128] (4) Measure 100ml of water, add 0.6g of polyacrylamide, after completely dissolving, add 3.5g of walnut shells with a particle size ranging from 0.1 to 5mm to form a stable dispersion. Use the polymer dispersion with a rated displacement of 20-30m 3 / h small centrifugal pump evenly and slowly added to the solution obtained in step (3), and...

Embodiment 3

[0132] Material compatibility scheme: powder material (hydration expansion agent + anti-pressure agent) + mineral oil + surfactant complex agent + polymer glue liquid, the specific compatibility is as follows:

[0133] (1) Measure 100ml of diesel oil, add OA 0.15g, SP-850.8g, EO-500.3g to dissolve;

[0134] (2) A small amount of water was added to G-2630.15g to dissolve, and then added to the solution obtained in step (1);

[0135] (3) add 100g bentonite, 13g MgO, 12g fly ash, 3g cement, 7g limestone, 4.5g slag, 1g silica fume successively in the solution that step (2) obtains, stir 1 hour;

[0136] (4) Measure 100ml of water, add 0.65g of polyacrylamide, after complete dissolution, add 3.5g of walnut shell with a particle size range of 0.1-5mm, and 0.5g of Lett fiber material to form a stable dispersion. Use the polymer dispersion with a rated displacement of 20-30m 3 / h small centrifugal pump evenly and slowly added to the solution obtained in step (3), and continued to st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com