Method for carrying out oil-water separation on micro-emulsion by utilizing magnetic field

A technology of oil-water separation and microemulsion, which is applied in separation methods, liquid separation, immiscible liquid separation, etc., and can solve problems such as large demand and inability to recycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

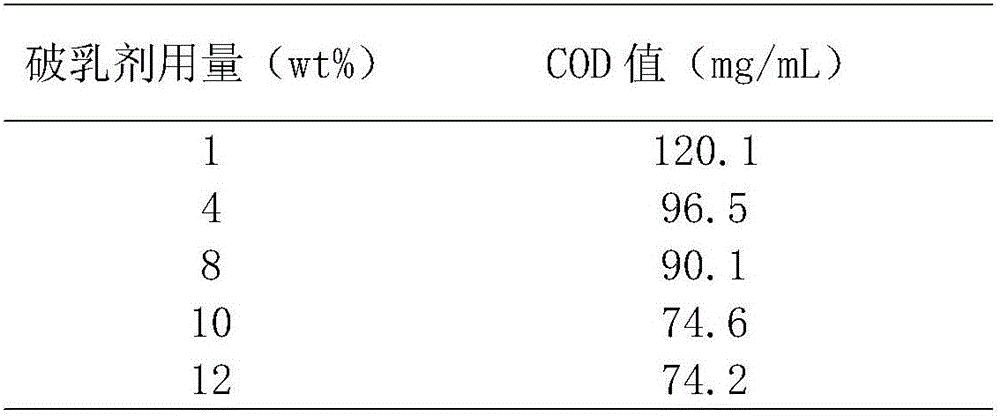

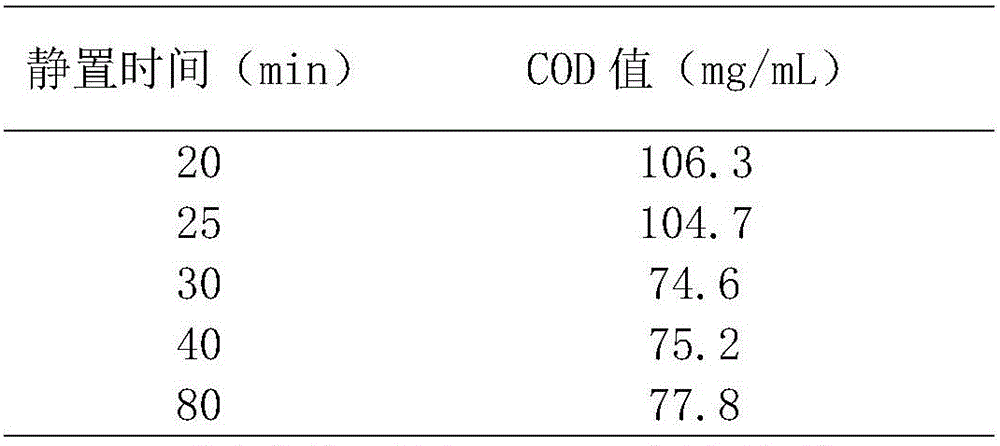

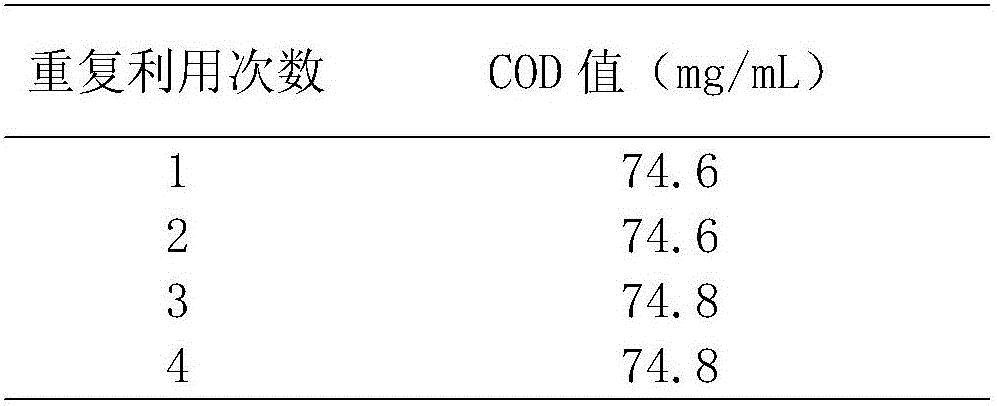

[0055] Sample: colored and transparent Tuha oilfield wastewater, COD value: 425mg / mL.

[0056] After demulsification by the above method, the COD value dropped to 74.6mg / mL.

Embodiment 2

[0058] Sample: Colorless and transparent banknote printing and papermaking wastewater, COD value: 342mg / mL.

[0059] After demulsification by the above method, the COD value dropped to 72.9mg / mL.

Embodiment 3

[0061] Sample: Colorless and transparent deinking papermaking wastewater, 166mg / mL.

[0062] After demulsification by the above method, the COD value dropped to 75.8mg / mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com