Method for preparing water-based polyurethane resin and water-based polyurethane resin

A water-based polyurethane and resin technology, applied in the field of polyurethane resin, can solve the problems of poor hydrolysis resistance, poor flame retardancy, and poor performance of water-based ecological synthetic leather, and achieve the effect of enhancing compatibility and compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

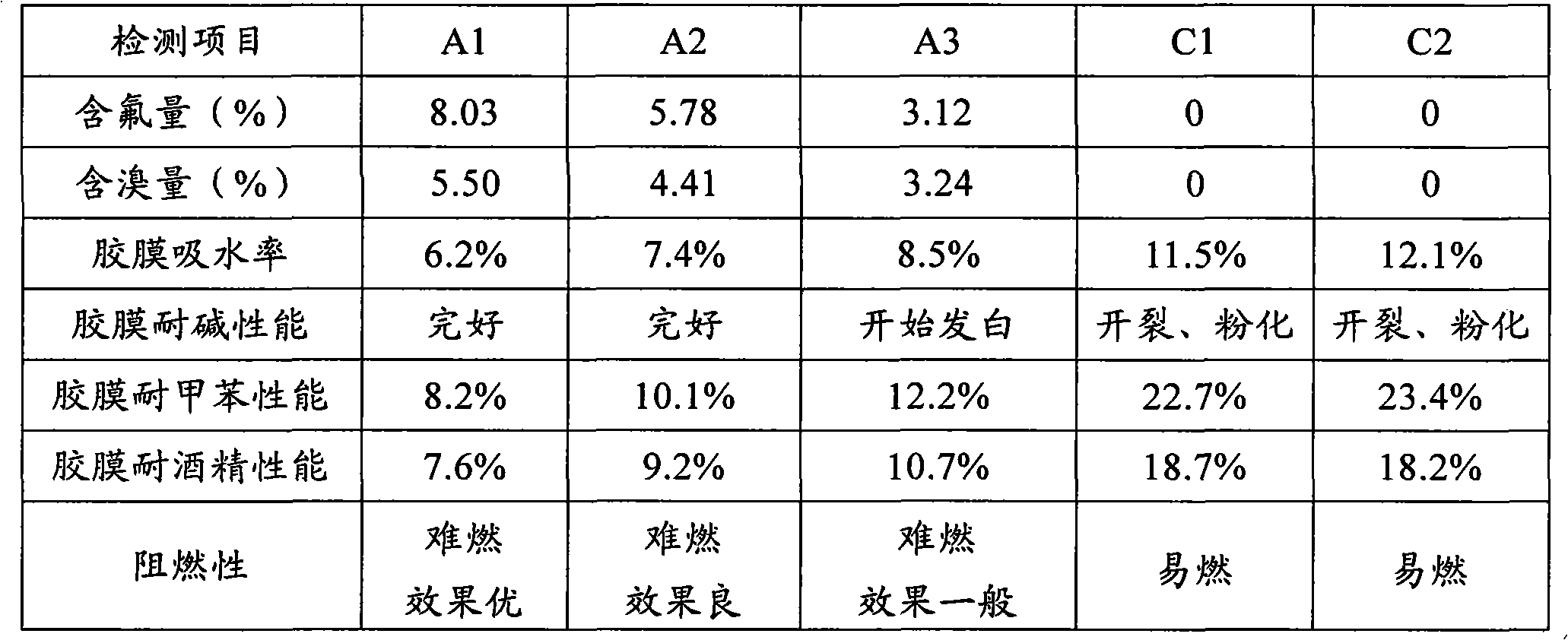

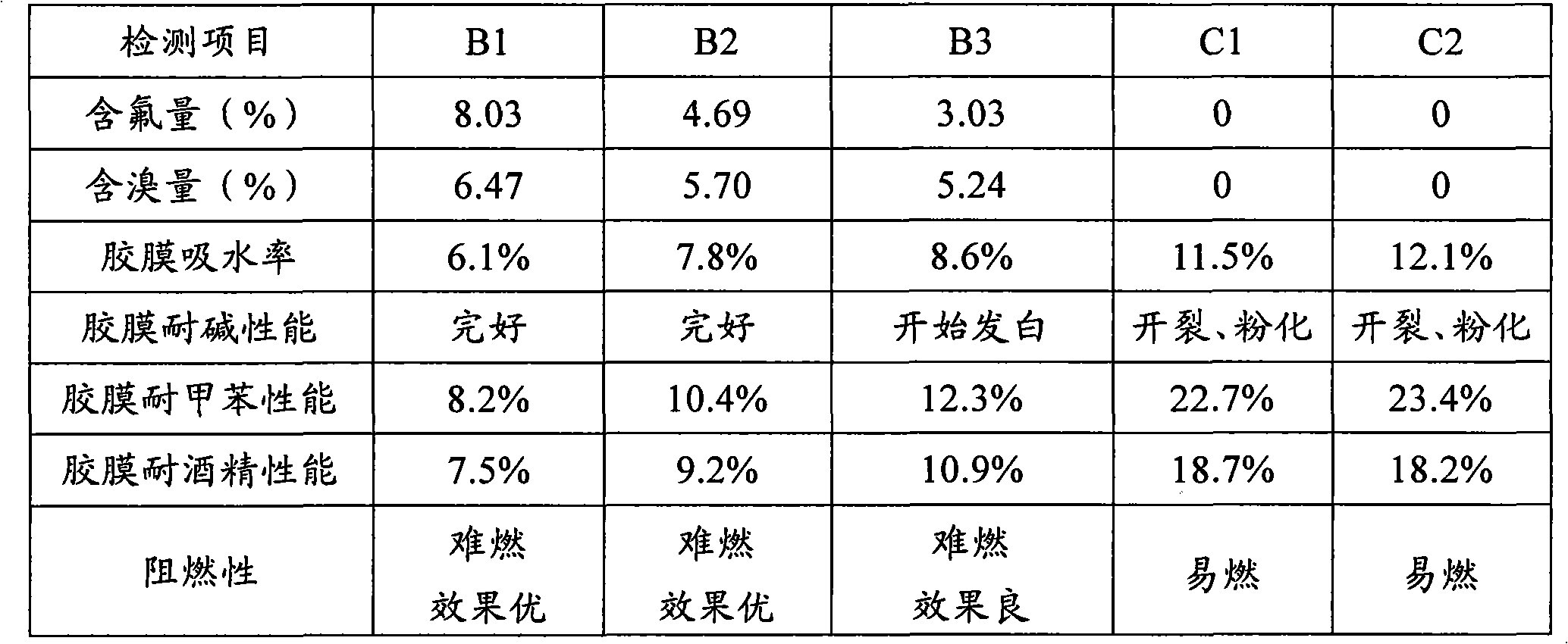

Embodiment 1

[0029] This embodiment is used to illustrate the preparation method of the waterborne polyurethane resin provided by the invention.

[0030] (1) Preparation of fluorine-containing diols

[0031] 20g of diethanolamine and 63.35g of dodecafluoroheptyl methacrylate were heated and refluxed at 80°C for 6 hours under the protection of nitrogen, and samples were taken every 30 minutes to measure their UV-vis spectra until the absorption peak remained basically unchanged. Wash 6 times with ethanol, 10ml each time, distill out acetocyanide and unreacted raw materials under reduced pressure to obtain 50.56g of product (yield rate: 63.2%).

[0032] (2) Preparation of prepolymer

[0033] Add 100.04g of isophorone diisocyanate to 100g of polytetrahydrofuran ether glycol (Mn=2000) and 50.5g (Mn=505.2) of the fluorine-containing diol mixed system prepared in step (1), at 80°C React for 120 minutes.

[0034] (3) Chain extension reaction

[0035]After step (2) finished, the reaction syste...

Embodiment 2

[0041] This embodiment is used to illustrate the preparation method of the waterborne polyurethane resin provided by the invention.

[0042] (1) Preparation of fluorine-containing diols

[0043] 12.28g of diethanolamine and 38.88g of dodecafluoroheptyl methacrylate were heated and refluxed at 80°C for 6 hours under the protection of nitrogen, and samples were taken every 30 minutes to measure their UV-vis spectra until the absorption peak remained basically unchanged. Wash with ethanol 6 times, 10ml each time, and distill out acetocyanide and unreacted raw materials under reduced pressure to obtain 30.9g (60.4% yield) of the product.

[0044] (2) Preparation of prepolymer

[0045] Add 73.36g of isophorone diisocyanate to 100g of polytetrahydrofuran ether glycol (Mn=2000) and 30.3g (Mn=505.2) of the fluorine-containing diol mixed system prepared in step (1), at 80°C React for 120 minutes.

[0046] (3) Chain extension reaction

[0047] After step (2) finished, the reaction s...

Embodiment 3

[0053] This embodiment is used to illustrate the preparation method of the waterborne polyurethane resin provided by the invention.

[0054] (1) Preparation of fluorine-containing diols

[0055] 7.94g of diethanolamine and 25.12g of dodecafluoroheptyl methacrylate were heated and refluxed at 75°C for 6 hours under nitrogen protection, and samples were taken every 30 minutes to measure their UV-vis spectra until the absorption peak remained basically unchanged. Wash with ethanol 6 times, 10ml each time, and distill out acetocyanide and unreacted raw materials under reduced pressure to obtain 21.07g of the product (63.76% yield).

[0056] (2) Preparation of prepolymer

[0057] Add 73.36g of isophorone diisocyanate into 160g of polytetrahydrofuran ether glycol (Mn=2000) and 20.2g (Mn=505.2) of the fluorine-containing diol mixed system prepared in step (1), and react at 80°C 120 minutes.

[0058] (3) Chain extension reaction

[0059] After step (2) finished, the reaction syste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com