Loaded and non-loaded catalyst and preparing method

A catalyst and protective agent technology, applied in the field of supported and unsupported metal catalysts and preparation, can solve the problems of reducing agent toxicity, difficult to control the particle size and crystal plane orientation of catalyst active components, etc., to achieve environmental friendliness, Reduce adverse effects, controllable particle size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

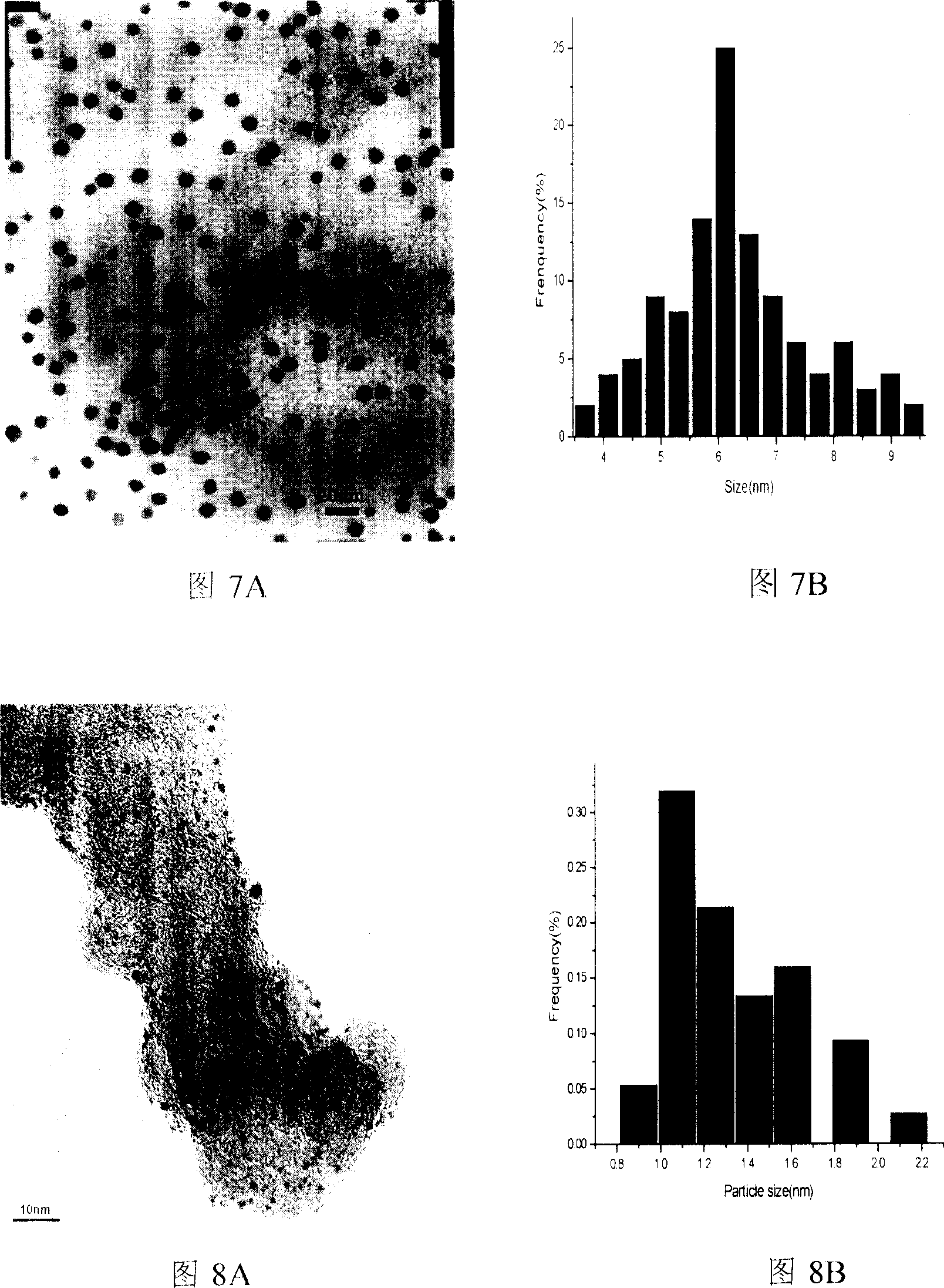

[0040] The preparation process of sample 1 is as follows: preparation of chloroplatinic acid solution: 1 gram of chloroplatinic acid is dissolved in a mixed solvent of 50 milliliters of water and 50 milliliters of ethylene glycol, and stirred evenly; preparation of protective agent solution: 1 gram of polyvinylpyrrolidone (PVP) was dissolved in a mixed solvent consisting of 50ml of water, 50ml of ethylene glycol, and 100% of ethanol, and stirred evenly. Mix the above two solutions, stir evenly, add 2ml 1mol / L NaOH ethylene glycol solution, raise the temperature to 130°C, stir, keep for 2 hours, cool down to room temperature, filter, wash with water, and centrifuge to collect the black sediment. Dry at 80° C. for 8 hours to obtain a platinum catalyst in which polyvinylpyrrolidone (PVP) is used as a protecting agent (stabilizer) and ethylene glycol is used as a reducing agent.

Embodiment 2

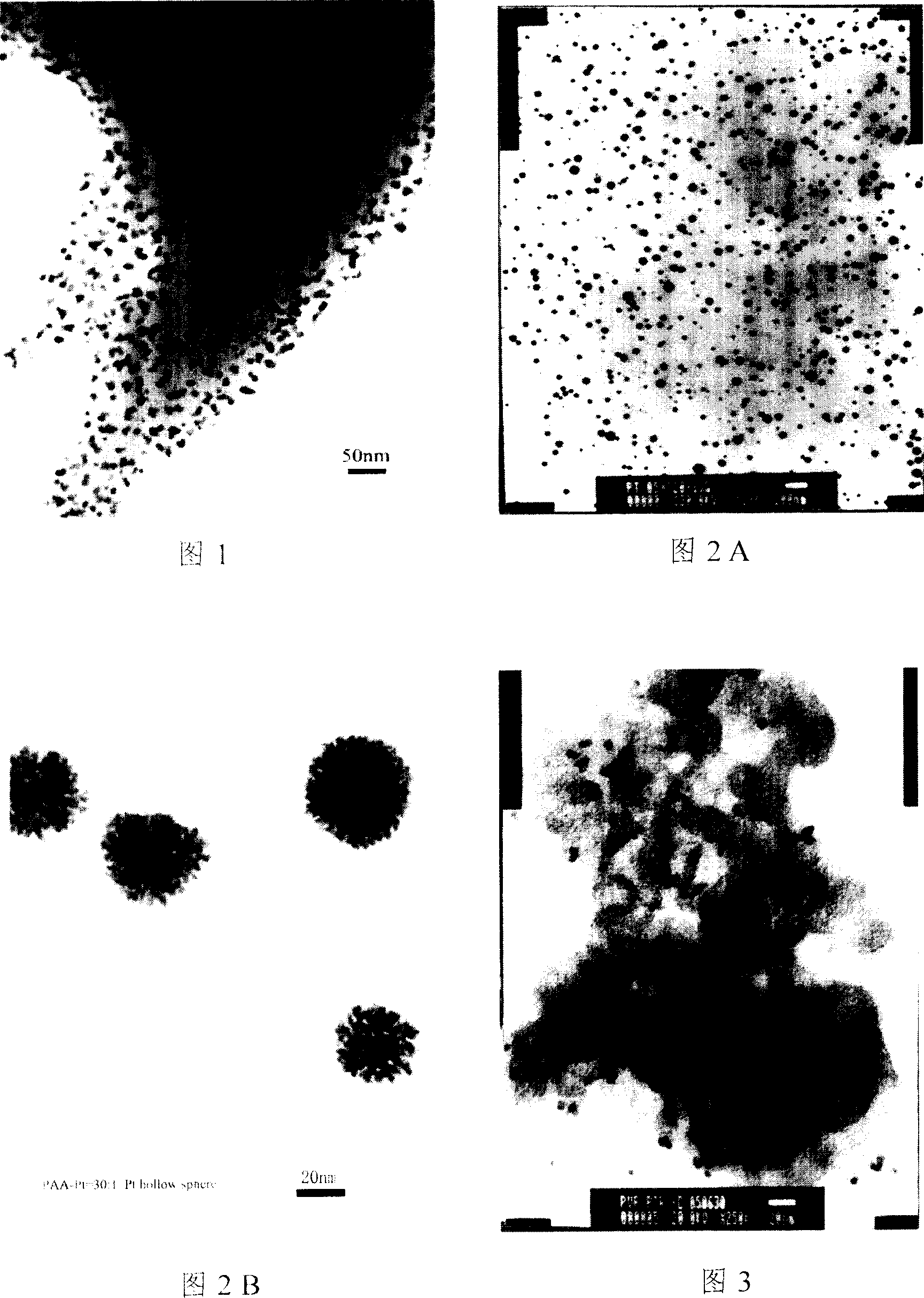

[0042] The preparation process of sample 2 is as follows: preparation of chloroplatinic acid solution: 1 gram of chloroplatinic acid is dissolved in a mixed solvent of 50 milliliters of water and 50 milliliters of ethylene glycol, and stirred evenly; preparation of protective agent solution: 500 milligrams of sodium polyacrylate (PAA) was dissolved in a mixed solvent consisting of 50ml of water, 50ml of ethylene glycol, and 100% of ethanol, and stirred evenly. Mix the above two solutions, stir evenly, add 2ml 1mol / L NaOH ethylene glycol solution, stir evenly, pass in hydrogen gas, keep for 10 minutes, continue stirring for 6 hours, filter, wash with water, add a mixed solution of acetone and ethanol as Sedimentation agent, centrifugal separation, collect black sedimentation material, dry at 80°C for 8 hours to obtain sodium polyacrylate (PAA) as protective agent (stabilizer), hydrogen and ethanol as reducing agent, mixed solution of acetone and ethanol as sedimentation agent p...

Embodiment 3

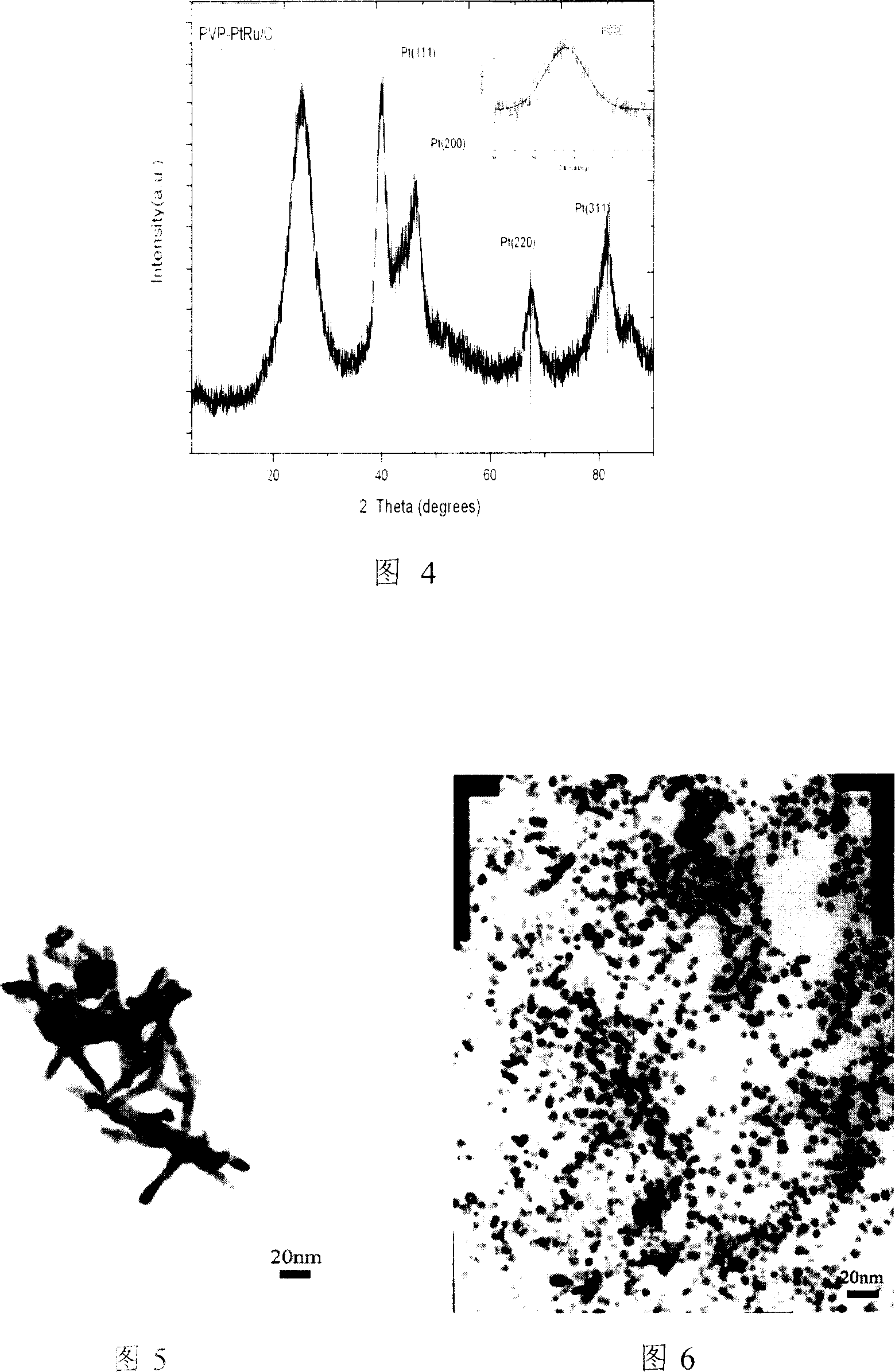

[0044] The preparation process of sample 3 is as follows: preparation of chloroplatinic acid solution: 1 gram of chloroplatinic acid is dissolved in a mixed solvent of 150 milliliters of water and 150 milliliters of ethylene glycol, and stirred evenly; preparation of ruthenium trichloride solution: 1 gram of trichloride Ruthenium chloride trihydrate is dissolved in the mixed solvent that 50 milliliters of water, 50 milliliters of ethylene glycols and 100 milliliters of ethanols form, stir well; Configure protective agent solution: 1 gram of polyvinylpyrrolidone (PVP) is dissolved in 50ml water, 50 milliliters In a mixed solvent composed of ethylene glycol and 100% ethanol, stir well. Mix the above three solutions, stir evenly, add 8ml 1mol / L NaOH glycol solution, stir evenly, pass in hydrogen, keep for 15 minutes, continue stirring for 6 hours, add 5g of XC-72R dispersed in ethylene glycol Carbon powder, add 1.5mol / L hydrochloric acid aqueous solution as a sedimentation agent,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com