Modified graphene-loaded polyurethane sponge and preparation method thereof

A polyurethane sponge, graphene technology, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as unresearched

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] For the preparation method of graphite oxide, please refer to the literature: Singh, E., Chen, Z., Houshmand, F., Ren, W., Peles, Y., Cheng, H. M. and Koratkar, N., Superhydrophobic graphene foams, Small, 2013 , 9(1): 75-80.

[0022] (2) Test sponge

[0023] Polyurethane sponge (density 0.025g / cm 3 ), purchased from local manufacturers.

[0024] (3) Experimental instruments and equipment

[0025] Heat-collecting magnetic stirrer, FA1004B—analytical balance, vacuum drying oven, oven, ultrasonic cleaning machine, high-speed centrifuge, water bath, vacuum filter pump, magnetic stirring oil bath

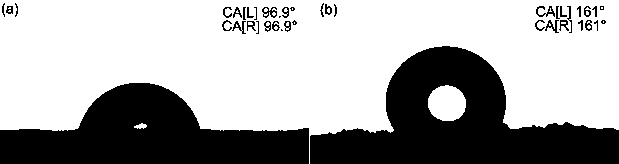

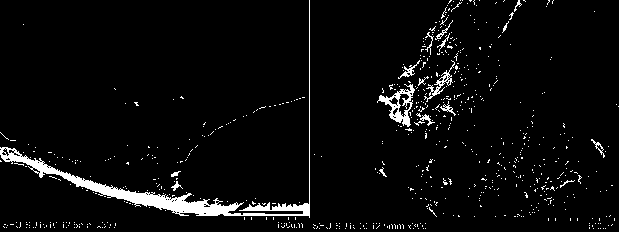

[0026] 2. Treatment of sponges and determination of their hydrophobic and lipophilic properties

[0027] (1) Disposal of sponge

[0028] The sponges were ultrasonically cleaned with deionized water and ethanol until use.

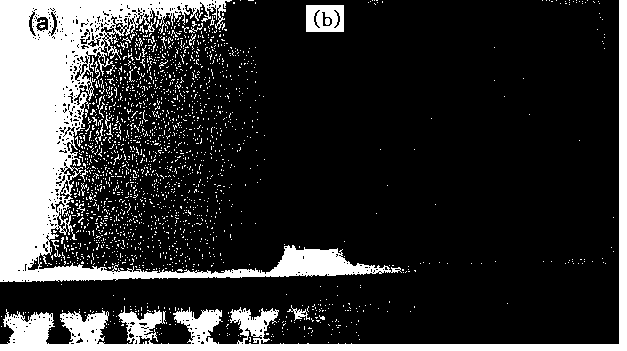

[0029] (2) Test oil

[0030] Zero Diesel (Sinopec Minghe Gas Station).

Embodiment 1

[0032] 1) Preparation of graphene oxide (GO). The main method is to add 2g of natural flake graphite to a 500mL beaker in an ice-water bath, and then add 46mL of concentrated H 2 SO 4 (98%), add 1g NaNO 3 , control the temperature below 20°C, add 6g KMnO while stirring 4 , raise the temperature to 35~36°C, keep the solution at this temperature for 1.5h, at this time, gas will be released; slowly add 92mL deionized water into the mixture, then raise the temperature of the water bath to 98°C, and keep it there for 15min , to increase the degree of oxidation of GO; dilute the mixture with 280mL deionized water, and dilute 6mL 30% H 2 o 2 Slowly add the solution to the above solution. If no bright yellow is formed, continue to add dropwise until bright yellow is formed. The mixture is filtered or centrifuged, and washed with 5% HCl solution for several times until it is washed with BaCl 2 SO not detected 4 2- , and then washed with deionized water several times to remove th...

Embodiment 2

[0036] 1) Preparation of graphene oxide (GO). The main method is to add 2g of natural flake graphite to a 500mL beaker in an ice-water bath, and then add 46mL of concentrated H 2 SO 4 (98%), add 1g NaNO 3 , control the temperature below 20°C, add 6g KMnO while stirring 4 , raise the temperature to 35~36°C, keep the solution at this temperature for 1.5h, at this time, gas will be released; slowly add 92mL deionized water into the mixture, then raise the temperature of the water bath to 98°C, and keep it there for 15min , to increase the degree of oxidation of GO; dilute the mixture with 280mL deionized water, and dilute 6mL 30% H 2 o 2 Slowly add the solution to the above solution, if no bright yellow is formed, continue to add dropwise until bright yellow is formed, the mixture is filtered or centrifuged, washed with 5% HCl solution for several times until it is washed with BaCl 2 SO not detected 4 2- , and then washed with deionized water several times to remove the ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com